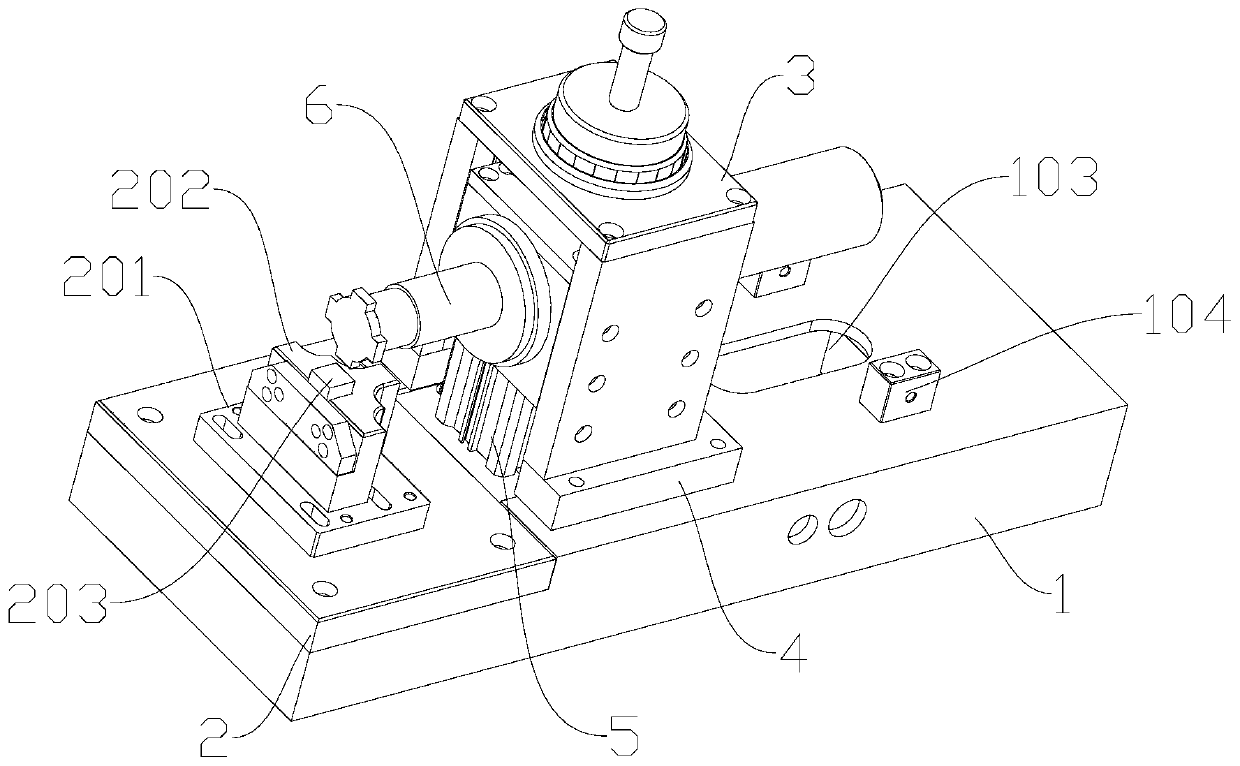

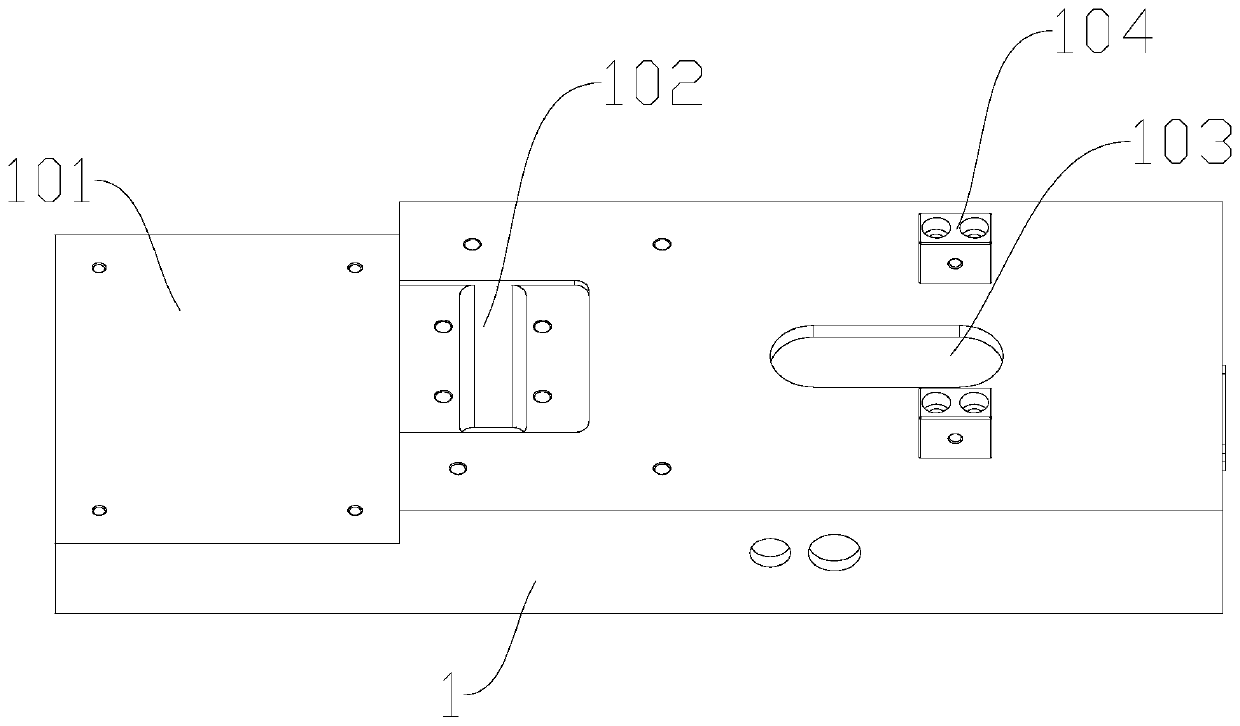

Ultrasonic welding device applied to vapor chamber and tailless sealing technology thereof

A technology of ultrasonic welding and uniform temperature plate, which is applied in the field of machinery, can solve the problems of low argon welding yield rate, low conversion rate of laser machine, insufficient bonding force, etc., and achieve good welding effect, good fusion effect and uniform internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

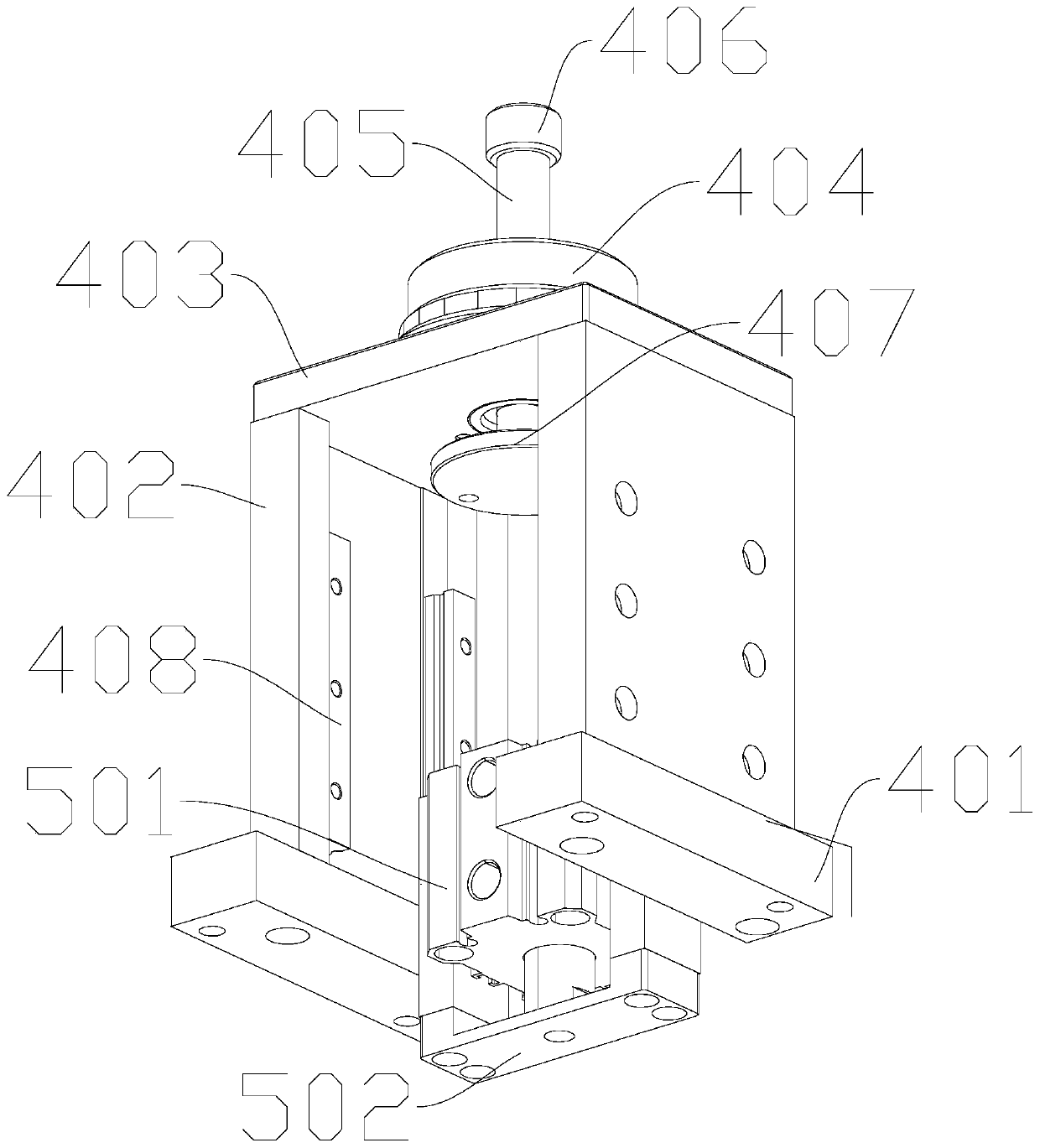

[0043] The specifications of the welded joints on the uniform temperature plate: copper metal substrate (length: 30mm, width: 5mm, thickness: 0.5mm); copper metal cover plate (length: 30mm, width: 5mm, thickness: 0.5mm); tube body.

[0044] Use the above-mentioned ultrasonic welding device applied to the vapor chamber to implement the tailless sealing process on the vapor chamber. The working frequency of the ultrasonic component is set to 20khz, the working amplitude is 60um, and the working time is 0.5 seconds. After the end sealing treatment is completed, pull-out test and air-tight test are carried out on the welded part of the vapor chamber, and the following welding results are obtained: the pull-out force reaches 200N, and it does not leak in an air-tight environment of -2bar.

Embodiment 2

[0046] The specifications of the welded part of the surplus part on the uniform temperature plate: copper metal substrate (length: 20mm, width: 4mm, thickness: 0.3mm); copper metal cover plate (length: 20mm, width: 4mm, thickness: 0.3mm); tube body.

[0047] Use the above-mentioned ultrasonic welding device applied to the vapor chamber to implement the tailless sealing process on the vapor chamber. The working frequency of the ultrasonic component is set to 30khz, the working amplitude is 30um, and the working time is 0.6 seconds. After the end sealing treatment is completed, pull-out test and air-tight test are carried out on the welded part of the vapor chamber, and the following welding results are obtained: the pull-out force reaches 100N, and it does not leak in an air-tight environment of -1 bar.

Embodiment 3

[0049] The specifications of the welded part of the surplus part on the uniform temperature plate: copper metal substrate (length: 15mm, width: 3mm, thickness: 0.2mm); copper metal cover plate (length: 15mm, width: 3mm, thickness: 0.2mm); tube body.

[0050] Adopt the above-mentioned ultrasonic welding device applied to the vapor chamber to implement the tailless sealing process on the vapor chamber. The working frequency of the ultrasonic component is set to 40khz, the working amplitude is 20um, and the working time is 0.8 seconds. After the end sealing treatment is completed, pull-out test and air-tight test are carried out on the welded part of the vapor chamber, and the following welding results are obtained: the pull-out force reaches 100N, and it does not leak in an air-tight environment of -1bar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com