Pigment ink and preparation method thereof

A technology of pigment ink and color paste, which is applied in the field of pigment ink and its preparation, can solve problems such as clogging, unstable pigments, substandard nozzles, etc., and achieve good stability, strong water resistance, and good fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

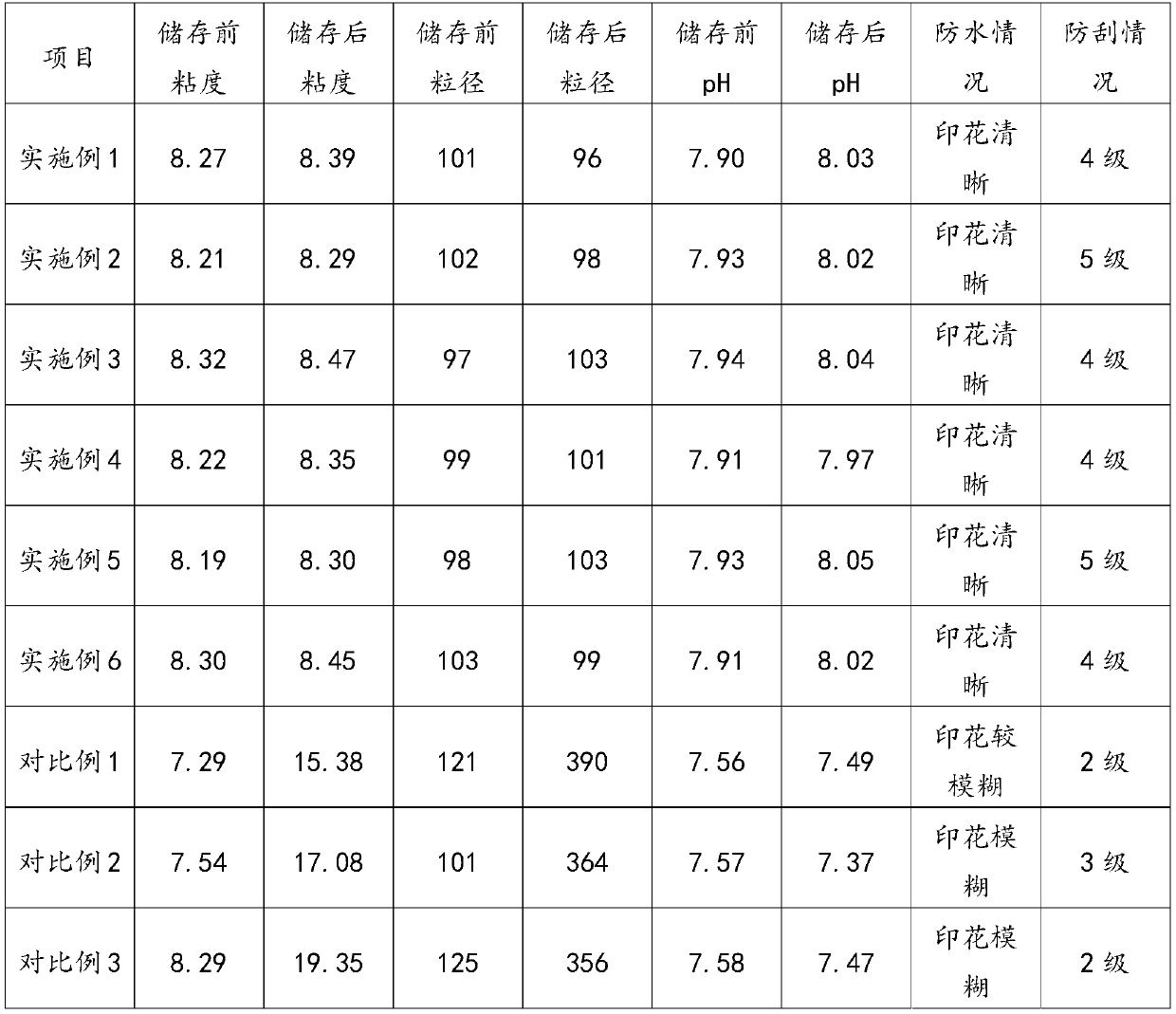

Examples

Embodiment 1

[0035] Weigh pigment red C.I.P.R.209, DISPERS 750W, and deionized water at a mass ratio of 30:15:55, mix them evenly, and add them to a sand mill equipped with zirconia balls after fully stirring. The filling rate of zirconia balls is 80 %, the diameter of the zirconium ball is 1mm, turn on the sand mill to increase the shear force to 12m / s, and carry out the production of color paste. During the production, the temperature is controlled at 34-40°C, and the particle size is monitored in real time. When D50<100, stop the machine , filter with a 0.5 micron PES filter membrane (purchased from PALL's polyethersulfone material) to obtain a color paste. 18.5 parts of polyvinyl alcohol, 2 parts of 2-methyl-4-isothiazolin-3-one, 1 part of triethanolamine, 10 parts of BYK800N, 5 parts of polyurethane resin, 10 parts of acrylic resin and 80 parts of deionized water , mixed at room temperature, fully stirred for 1 hour to obtain a mixed solution; 30 parts of color paste was added to the ...

Embodiment 2

[0037] Weigh Pigment Yellow C.I.P.Y.17, Corning Hydropalat 100, and deionized water at a mass ratio of 20:10:70, mix them evenly, and add them to a sand mill equipped with zirconia balls after fully stirring. The filling rate of zirconia balls is 80 %, the diameter of the zirconium ball is 2mm, turn on the sand mill to increase the shear force to 12m / s, and carry out the production of color paste. The temperature is controlled at 34-40°C during production, and the particle size is monitored in real time. When D50<100, stop , filter with a 0.3 micron PES filter membrane (purchase the polyethersulfone material of Sub-PALL Company) to prepare the color paste. Mix 10 parts of glycerol, 1 part of 2-methyl-4-isothiazolin-3-one, 2 parts of sodium hydroxide, 0.5 parts of air chemical 609, 6 parts of polyurethane resin and 65.5 parts of deionized water at room temperature Mix and fully stir for 1 hour to obtain a mixed solution; add 15 parts of color paste to the mixed solution, and fu...

Embodiment 3

[0039] Weigh Pigment Yellow C.I.P.Y.17, Corning Hydropalat 100, and deionized water at a mass ratio of 40:18:42, mix them evenly, and add them to a sand mill equipped with zirconia balls after fully stirring. The filling rate of zirconia balls is 80 %, the diameter of the zirconium ball is 2mm, turn on the sand mill to increase the shear force to 12m / s, and carry out the production of color paste. The temperature is controlled at 34-40°C during production, and the particle size is monitored in real time. When D50<100, stop , filter with a 0.3 micron PES filter membrane (purchase the polyethersulfone material of Sub-PALL Company) to prepare the color paste. Mix 10 parts of glycerol, 1 part of 2-methyl-4-isothiazolin-3-one, 2 parts of sodium hydroxide, 0.5 parts of air chemical 609, 6 parts of polyurethane resin and 65.5 parts of deionized water at room temperature Mix and fully stir for 1 hour to obtain a mixed solution; add 15 parts of color paste to the mixed solution, and fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com