High-power white-light LED light source based on transparent ceramic fluorescent tube

A technology of LED light source and transparent ceramics, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of uneven light intensity distribution, development and application limitations, poor light uniformity, etc., achieve uniform light emission, improve light efficiency, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

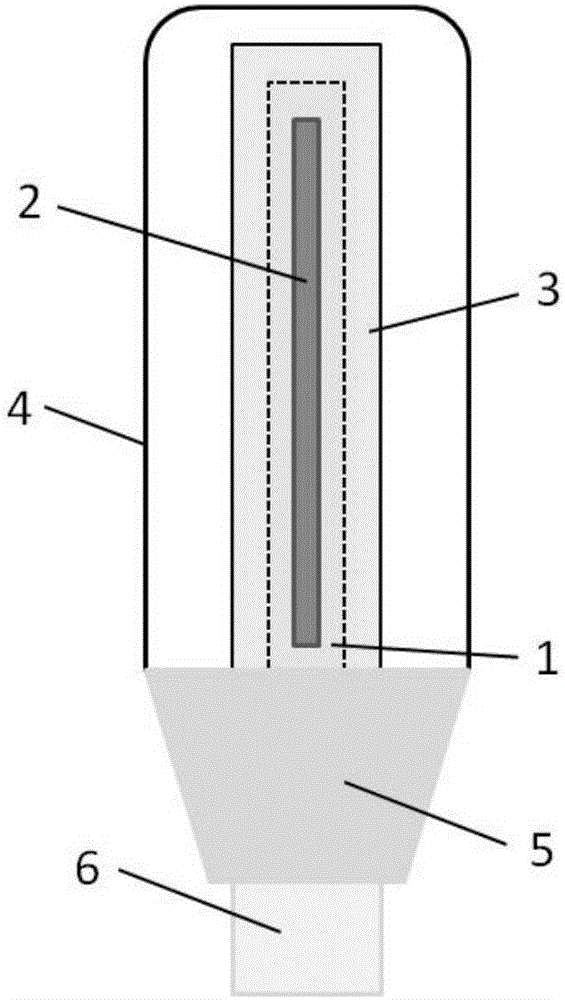

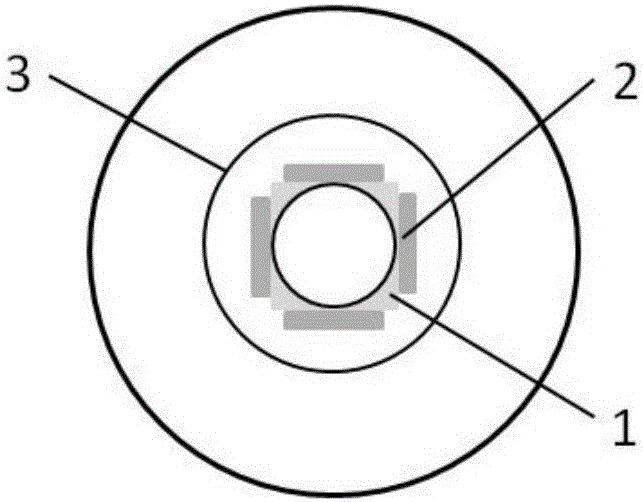

[0026] (1) Prepare mutually suitable metal heat-conducting columns 1, blue light chips 2, transparent ceramic fluorescent tubes 3, high light-transmitting packaging shells (polypropylene) 4, heat sinks 5 and electrodes 6;

[0027] (2) Arrange the COB blue-ray chips 2 with a thickness of 2mm in a linear and vertical manner at an interval of 3mm, and paste them on the rectangular metal heat conduction column 1 with a bottom side length of 15mm and a height of 100mm through silica gel. 1 70% of the surface area;

[0028] (3) A tubular Ce:YAG transparent ceramic fluorescent tube 3 is arranged outside the regular rectangular parallelepiped metal heat conduction column 1 with the COB blue light chip 2, and its transmittance at 550nm is 70%, and its density is 99.7%. Keep a distance of 20mm between them;

[0029] (4) The transparent ceramic tube 3 and the metal heat conduction column 1 are placed on the upper surface of the heat sink 5, and the commercially available screw electrode...

Embodiment 2

[0034] (1) Prepare mutually suitable metal heat-conducting columns 1, blue light chips 2, transparent ceramic fluorescent tubes 3, high light-transmitting packaging shells (polypropylene) 4, heat sinks 5 and electrodes 6;

[0035] (2) Arrange the blue LED lamp beads 2 with a thickness of 4mm linearly and vertically at an interval of 4mm, and paste them on the metal heat-conducting column 1 with a regular triangular prism shape with a bottom side length of 10mm and a height of 200mm through silica gel. 80% of the surface area of column 1;

[0036] (3) A hollow Ce:YAG transparent ceramic fluorescent tube 3 is set outside the regular triangular prism-shaped metal heat-conducting column 1 pasted with blue LED lamp beads 2, and its transmittance at 550nm is 75%, and its density is 99.0%. Keep a distance of 40mm between the two;

[0037] (4) The transparent ceramic tube 3 and the metal heat conduction column 1 are placed on the upper surface of the heat sink 5, and the commercial...

Embodiment 3

[0041] (1) Prepare mutually suitable metal heat-conducting columns 1, blue light chips 2, transparent ceramic fluorescent tubes 3, high light-transmitting packaging shells (polypropylene) 4, heat sinks 5 and electrodes 6;

[0042] (2) Arrange the COB Blu-ray chips 2 with a thickness of 2mm in a linear and vertical manner at an interval of 4mm, and paste them on the metal heat-conducting column 1 with a bottom side length of 15mm and a height of 40mm on the metal heat-conducting column 1 with a thickness of 2mm. 1 50% of the surface area;

[0043](3) A hollow Ce:YAG transparent ceramic fluorescent tube 3 is set outside the regular triangular prism-shaped metal heat-conducting column 1 with the COB blue-ray chip 2 attached, and its transmittance at 550nm is 72%, and its density is 99.3%. Keep a distance of 10mm between them;

[0044] (4) The transparent ceramic tube 3 and the metal heat conduction column 1 are placed on the upper surface of the heat sink 5, and the commercially...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com