IGBT device with high latching resisting capability

A latch and device technology, applied in the field of semiconductor devices, can solve the problems of IGBT device design and process difficulty, large conduction voltage drop of IGBT devices, and insignificant conductance modulation effect, so as to improve the anti-latch ability and reduce conduction. Pressure drop, downsizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific drawings and embodiments.

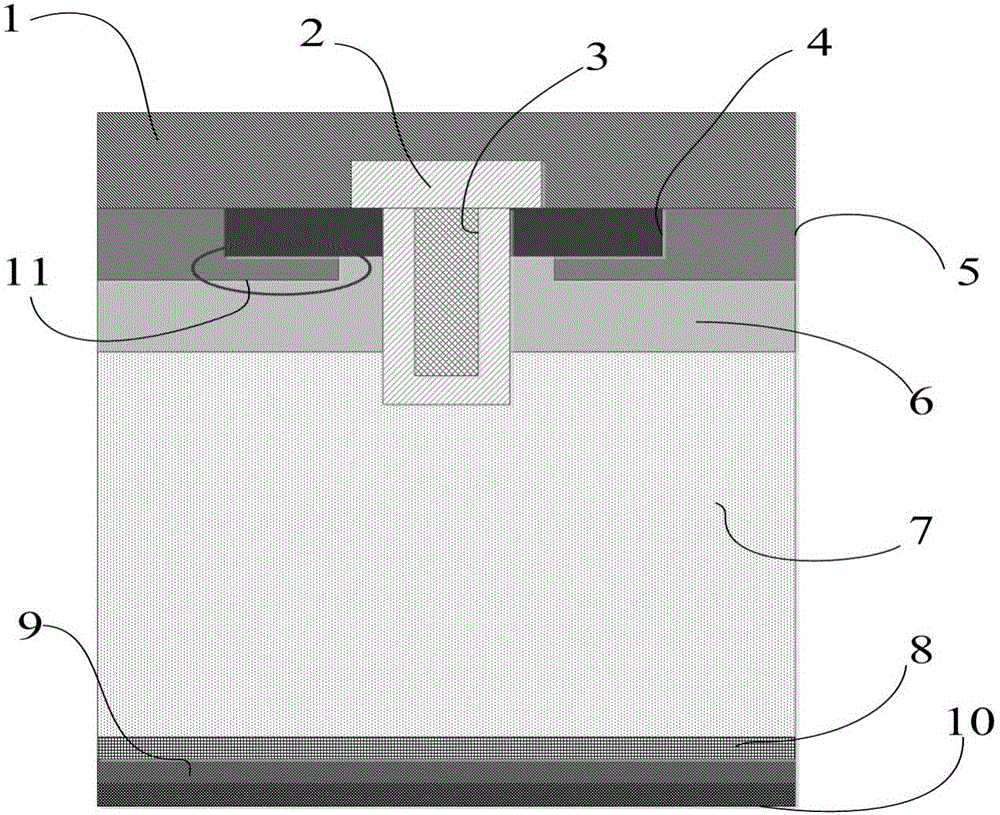

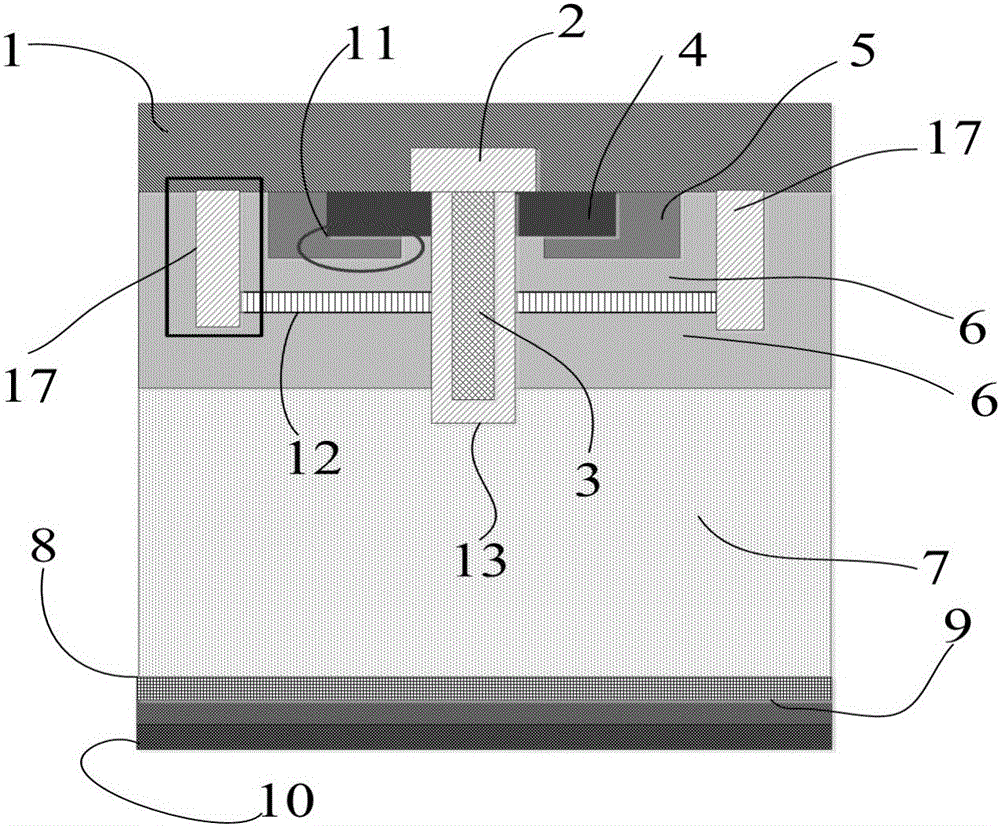

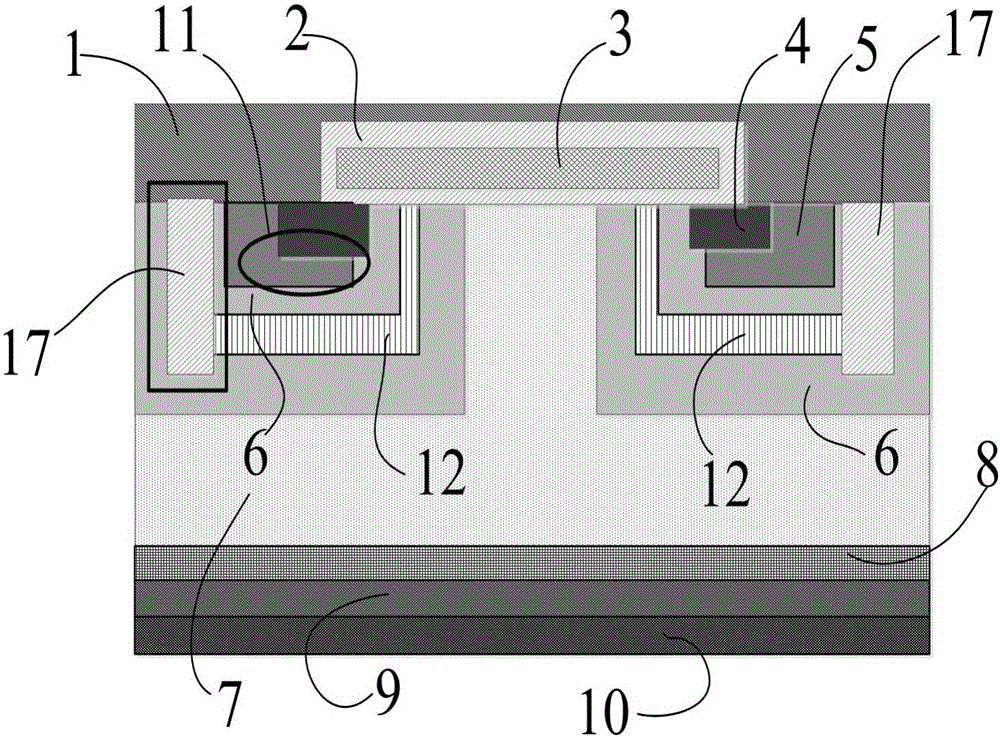

[0037] In order to effectively reduce the risk of latch-up and provide a basis for reducing the conduction voltage drop, taking an N-type IGBT device as an example, the present invention includes a semiconductor substrate with two opposite main surfaces, and the two opposite main surfaces of the semiconductor substrate include the first A main surface and a second main surface corresponding to the first main surface; an N-type base region 7 is included between the first main surface and the second main surface of the semiconductor substrate; several regular rows are arranged in the N-type base region 7 of the semiconductor substrate The active cells 16 distributed parallel to each other, the active cells 16 include the P-type base region 6 located in the upper part of the N-type base region 7 and the N+ source region 4 located in the P-type base region 6 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com