Heat dissipation structure, manufacturing method therefor, and device employing heat dissipation structure

A technology of heat dissipation structure and manufacturing method, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., and can solve the problems of affecting the computing efficiency of electronic equipment, high manufacturing cost, and poor heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

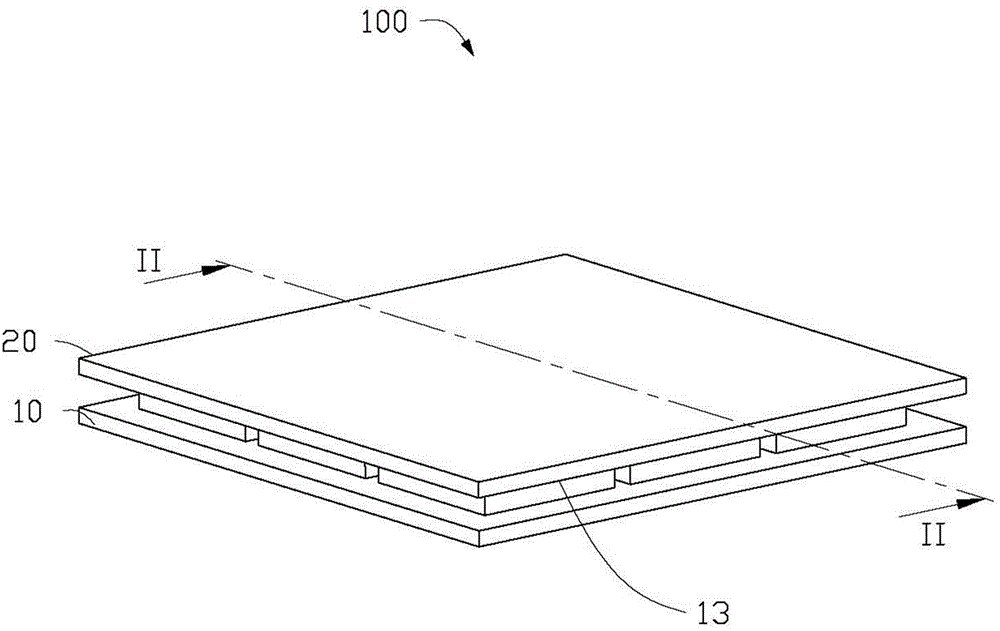

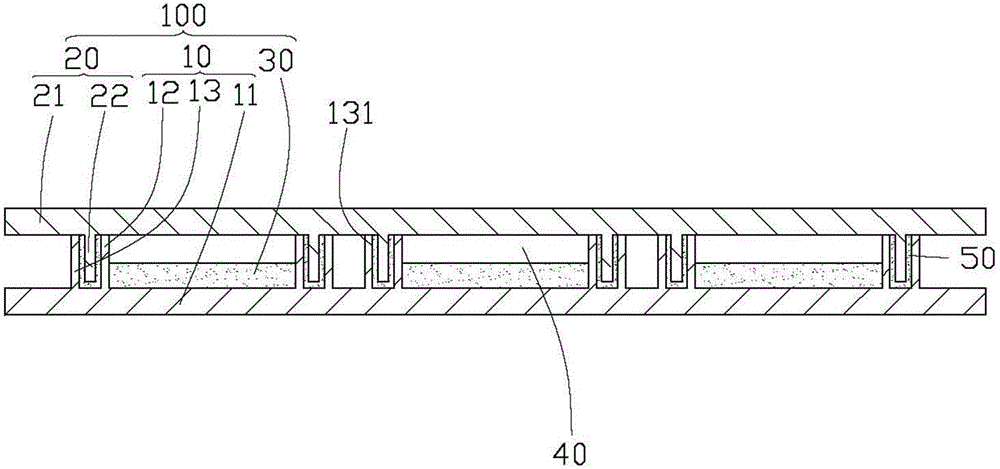

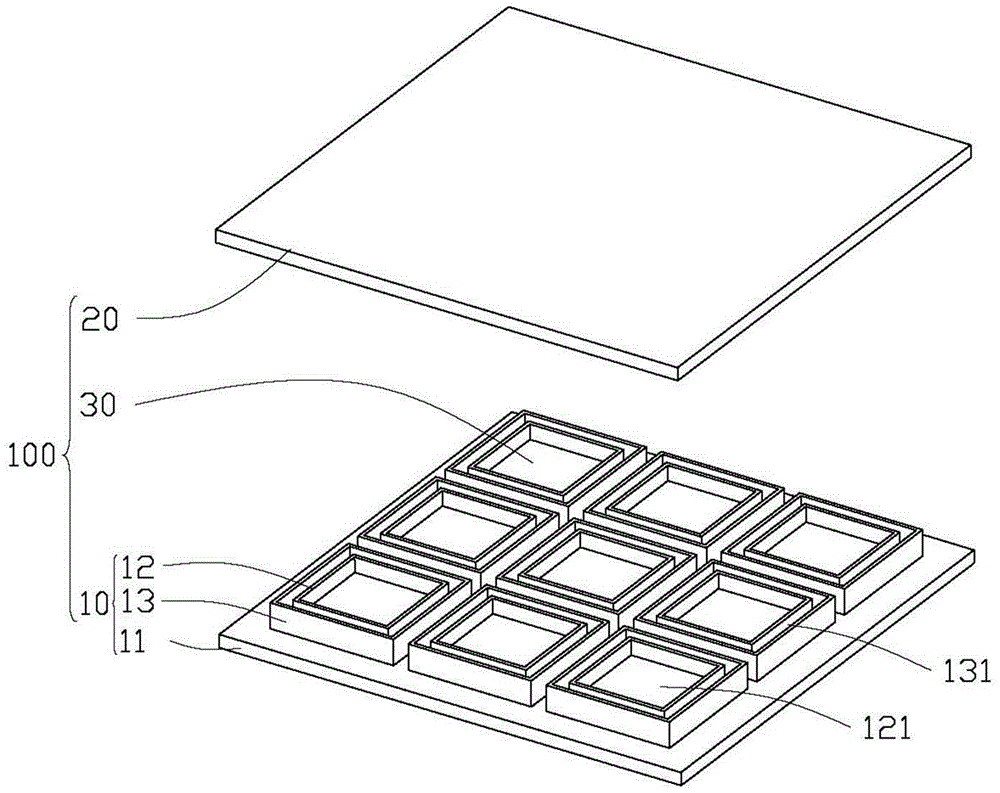

[0033] see Figure 1~2 , a preferred embodiment of the present invention provides a heat dissipation structure 100, which is used for heat-generating components (such as microprocessors, memory modules, cache memory, etc.) memory chips, etc.) for heat dissipation. The heat dissipation structure 100 includes a base 10 and a cover 20 covering the base 10 . At least one airtight cavity 40 is formed between the cover body 20 and the base 10 , and each airtight cavity 40 is filled with a radiator 30 .

[0034] Both the base 10 and the cover 20 are made of heat-conducting materials. The heat conducting material can be metal, and the metal is preferably copper.

[0035] The radiator 30 does not completely fill the airtight cavity 40 , and the radiator 30 is made of phase change material (PCM-PhaseChangMaterial). When the cooling body 30 absorbs heat to increase its temperature to the phase transition temperature, the cooling body 30 undergoes a phase change and further absorbs an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com