Full-automatic garlic clove tip aligning device

A fully automatic, garlic clove technology, applied in the field of agricultural and forestry machinery, can solve the problems of difficult popularization and application, uneven germination, low applicability, etc., and achieve the effect of excellent long-term operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

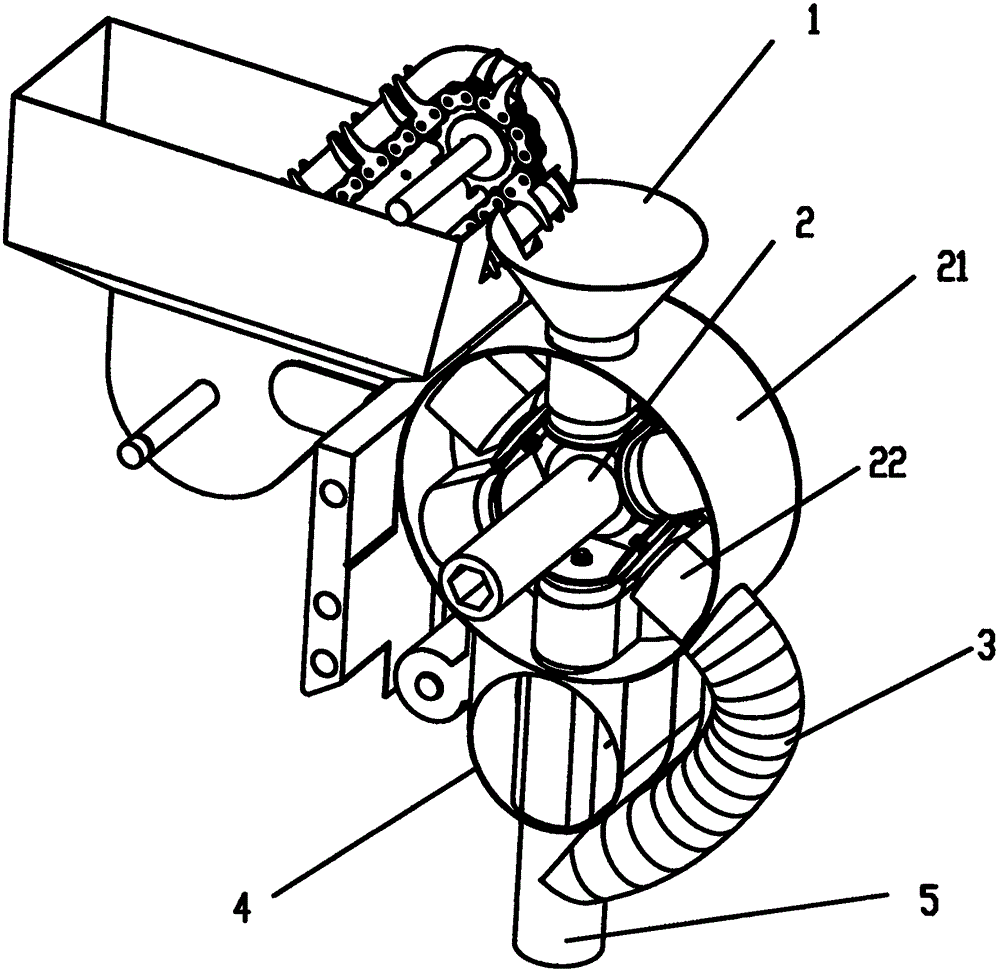

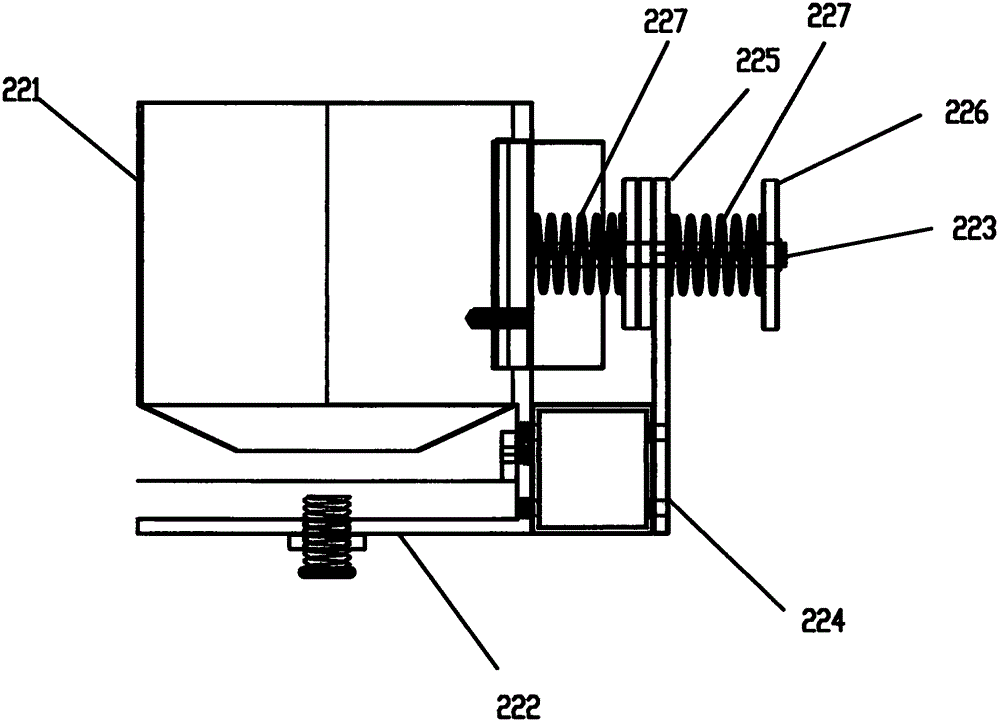

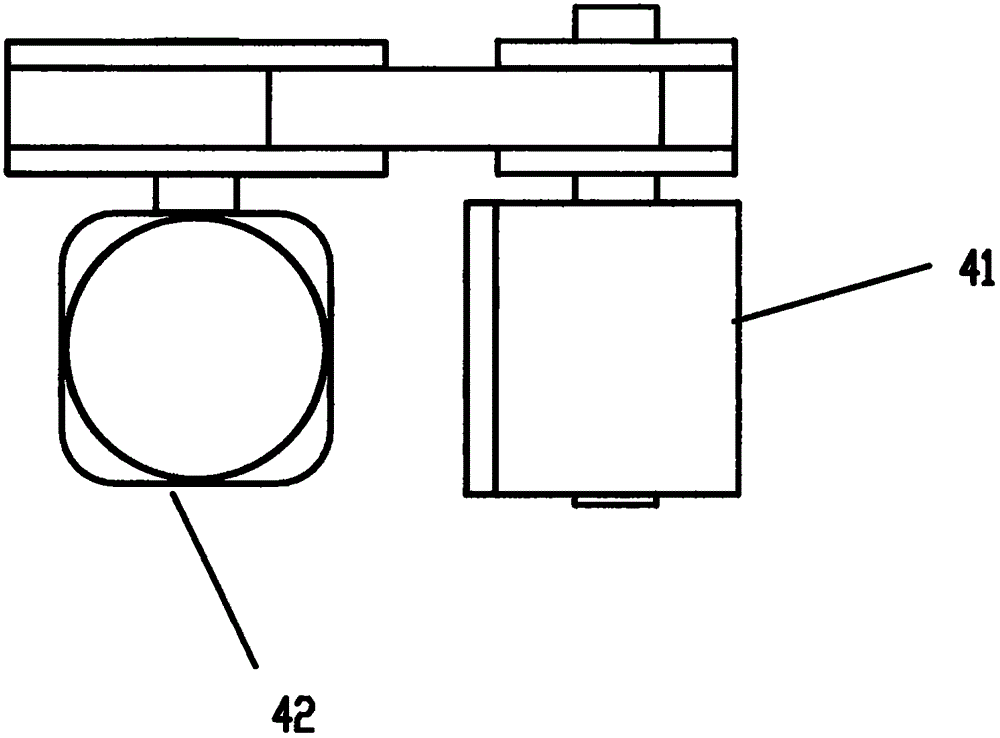

[0023]Referring to the accompanying drawings, the structure of a specific embodiment of the present invention includes a garlic receiving funnel 1, a rotary garlic storage mechanism 2 that accepts the garlic cloves dropped from the garlic receiving funnel 1, and a garlic delivery corrugated device arranged on one side of the rotary garlic storage mechanism 2. Pipe 3, the valve tip turning mechanism 4 arranged under the rotary garlic storage mechanism 2 and the garlic delivery tube 5 arranged below the valve tip turning mechanism 4; wherein, the upper end of the garlic delivery bellows 3 is arranged at the lower part of the rotary garlic storage mechanism 2 side and It is movably docked with the identification garlic storage cylinder 221 that is stepping and rotating; the rotating garlic storage mechanism 2 is installed under the garlic receiving funnel 1, which includes a set of rotatable stepping turntables 21 connected to the power mechanism and the stepping turntables set her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com