Harvesting device suitable for automatic production of cordyceps taishanensis

A cordyceps fungus and clamping device technology, applied in application, harvester, gardening, etc., can solve problems such as unclean decomposition, inability to meet mass production, and incompliance with food safety, etc., and achieve the effect of facilitating later production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

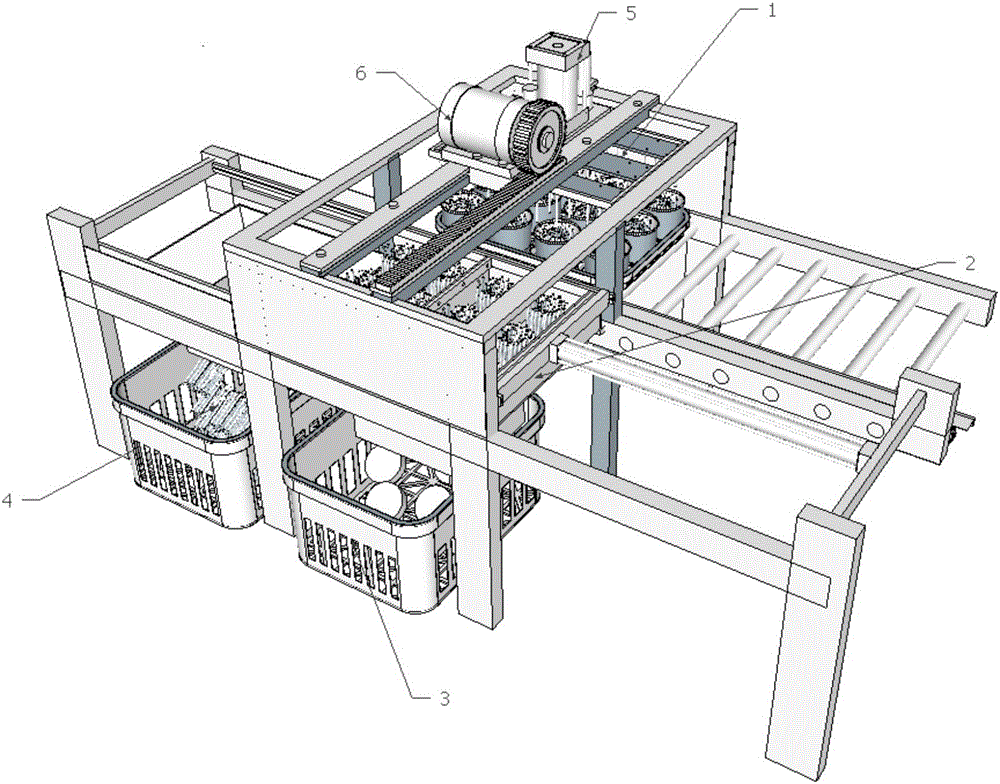

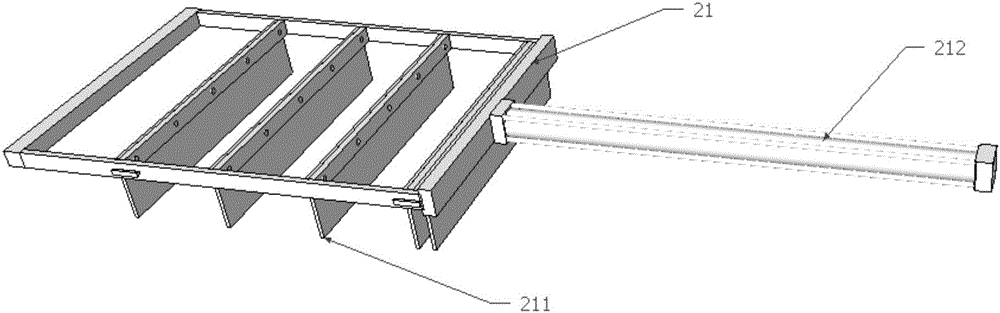

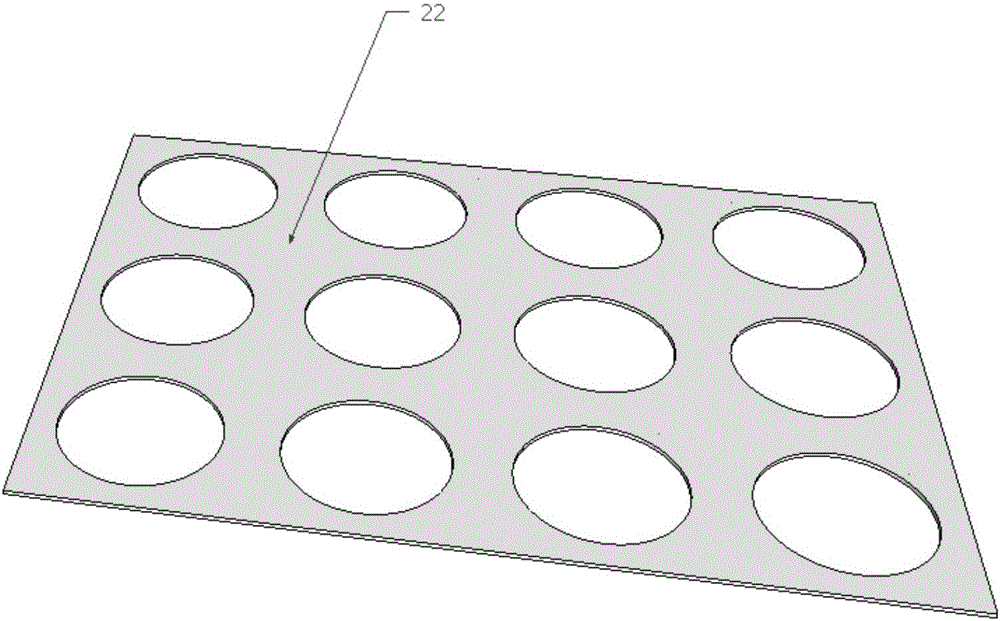

[0027] Such as figure 1 As shown, the harvesting device of the automatic production of Cordyceps fungus of the present invention includes a grabbing device and a cutting device 2, and the grabbing device is made up of a pin type grabbing plate 1, a longitudinal moving device 5 and a lateral moving device 6, and the longitudinal moving device 5 The pin-type grabbing plate 1 is connected below, and the lateral moving device 6 is connected with the longitudinal moving device 5 . The vertical moving device 5 moves downwards to grab the medium 7 for growing Cordyceps fungus in the breeding cup, and then the vertical moving device 5 is lifted upwards; at this time, the horizontal moving device 6 drives the vertical moving device and the medium 7 to move laterally to the cutting device 2 on.

[0028] The lateral moving device 6 moves to the top of the cutting device 2, auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com