A poultry electric heating tube heating depilation machine

An electric heating tube and hair removal machine technology, applied in poultry depilation machines, poultry processing, processed meat, etc., can solve the problems of affecting eating effect and aesthetics, skin damage of broilers, affecting health, etc., and achieves simple structure and rapid depilation , reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

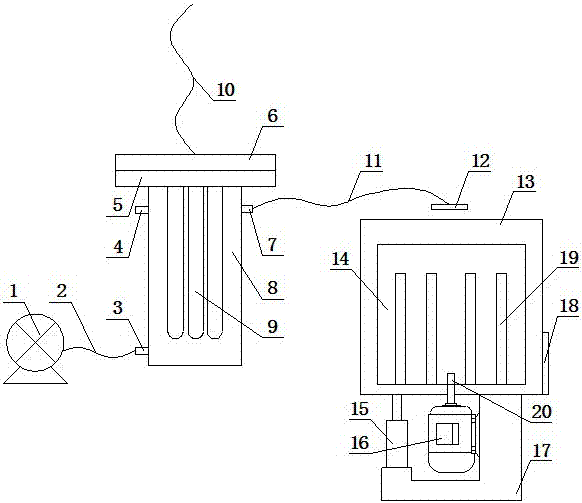

[0017] Such as figure 1 As shown, a poultry electric heating tube heating hair removal machine, it includes a heating device and a hair removal device, the heating device includes a housing 8, the top of the housing 8 is provided with a flange A5, the housing 8 An electric heating tube 9 is arranged inside, and the top end of the electric heating tube 9 is provided with a flange B6. The electric heating tube 9 is connected with an electric wire 10, and the upper part of the right side of the housing 8 is provided with a water outlet 7. The upper part on the left side of the housing 8 is provided with a temperature measuring port 4, the lower part on the left side of the housing 8 is provided with a water inlet 3, the water inlet 3 is connected to a water inlet pipe 2, and the water inlet pipe 2 is connected to There is a water pump 1, the water outlet 7 is connected with a water outlet pipe 11, and the end of the water outlet pipe 11 is provided with a nozzle 12; the hair remo...

Embodiment 2

[0020] Such as figure 1 As shown, a poultry electric heating tube heating hair removal machine, it includes a heating device and a hair removal device, the heating device includes a housing 8, the top of the housing 8 is provided with a flange A5, the housing 8 An electric heating tube 9 is arranged inside, and the top end of the electric heating tube 9 is provided with a flange B6. The electric heating tube 9 is connected with an electric wire 10, and the upper part of the right side of the housing 8 is provided with a water outlet 7. The upper part on the left side of the housing 8 is provided with a temperature measuring port 4, the lower part on the left side of the housing 8 is provided with a water inlet 3, the water inlet 3 is connected to a water inlet pipe 2, and the water inlet pipe 2 is connected to There is a water pump 1, the water outlet 7 is connected with a water outlet pipe 11, and the end of the water outlet pipe 11 is provided with a nozzle 12; the hair remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com