Fermentation production device for fermented bean curd production

A production device and fermented fermented bean curd technology are applied in the field of fermented fermented production of fermented bean curd production, which can solve the problems of low production efficiency, high labor intensity, and many equipment, so as to improve energy utilization and reduce operating labor costs. and production cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

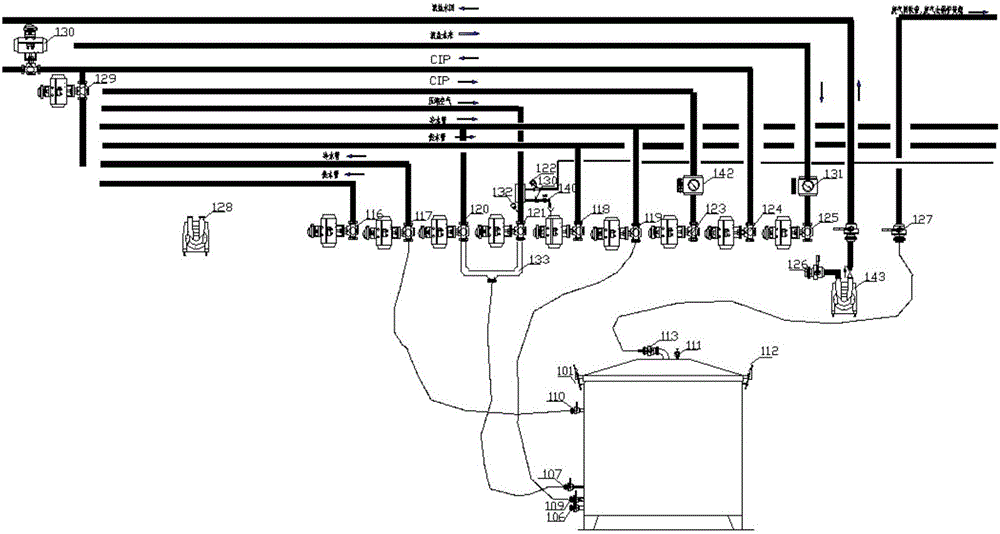

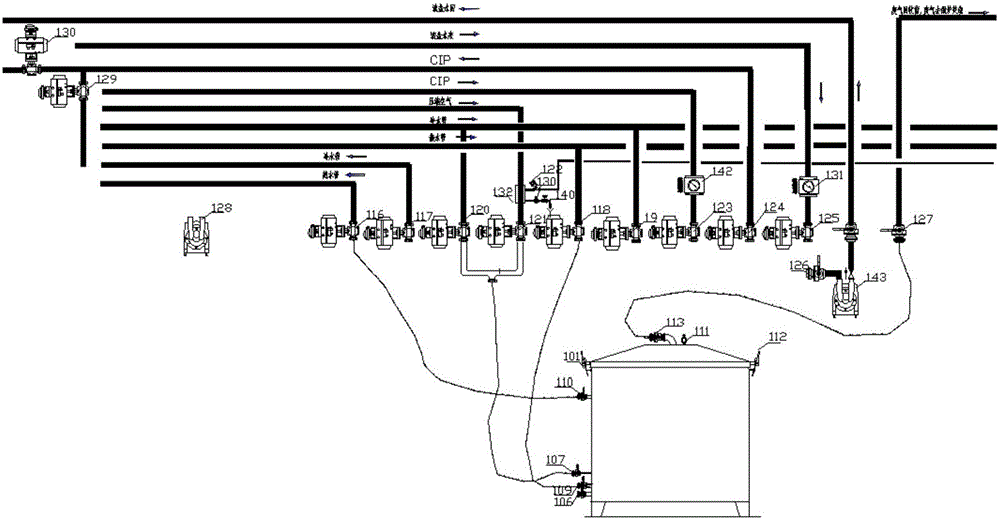

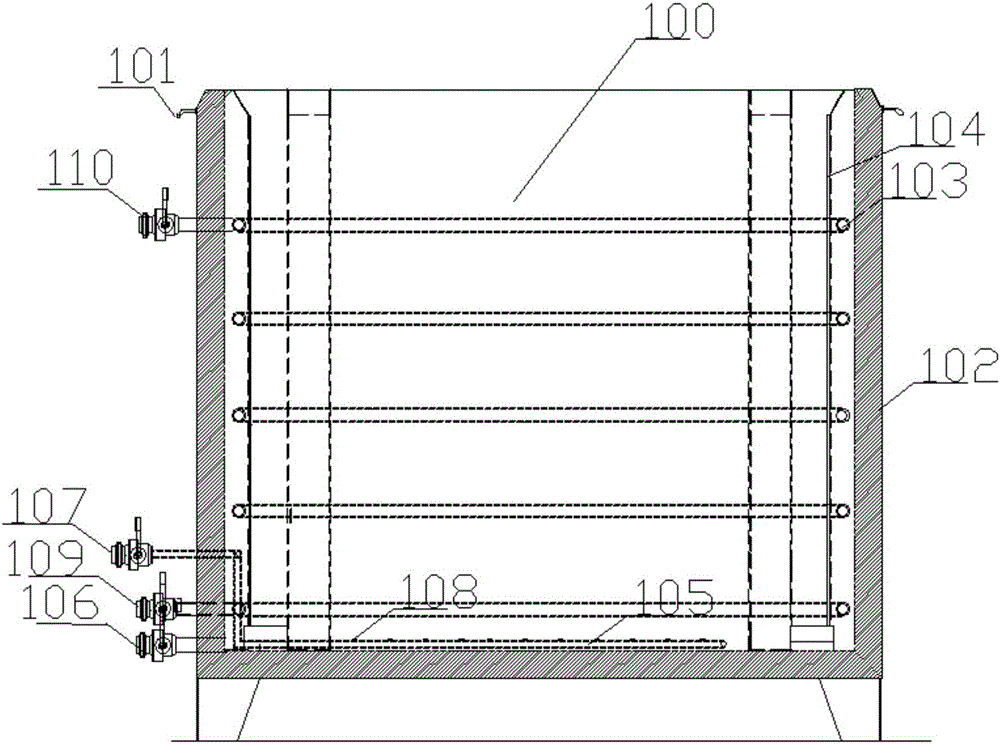

[0043] The fermentation production device suitable for fermented bean curd production of the present invention strives to preserve traditional production methods, combines traditional methods with current mechanized operations, pays attention to the recycling of production waste water and cleaning water, and correspondingly reduces operating labor costs, production costs and equipment investment costs , Completely change the current situation in the fermented fermented bean curd production process, the whole process has many production processes, high labor intensity, large production workshop area, many containers and equipment, and poor production sanitary conditions.

[0044] Aiming at the above-mentioned shortcomings in the existing fermented bean curd production technology, the present invention provides a fermented production device suitable for fermented bean curd production, and solves the defects of a large number of equipment for fermented bean curd production, high labor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com