Making method for cured roast duck neck

A production method and technology of roasted duck neck, which is applied in food science and other fields, can solve the problems of consumer food safety impact, duck neck without roasted flavor, short shelf life, etc., and achieve the effect of consistent taste, consistency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

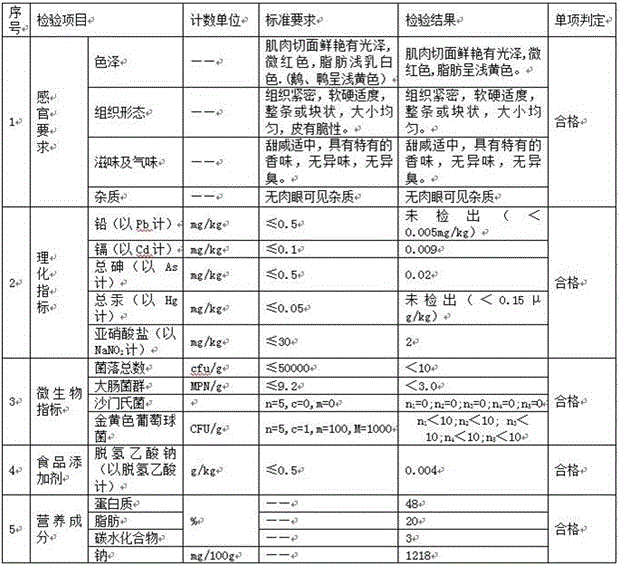

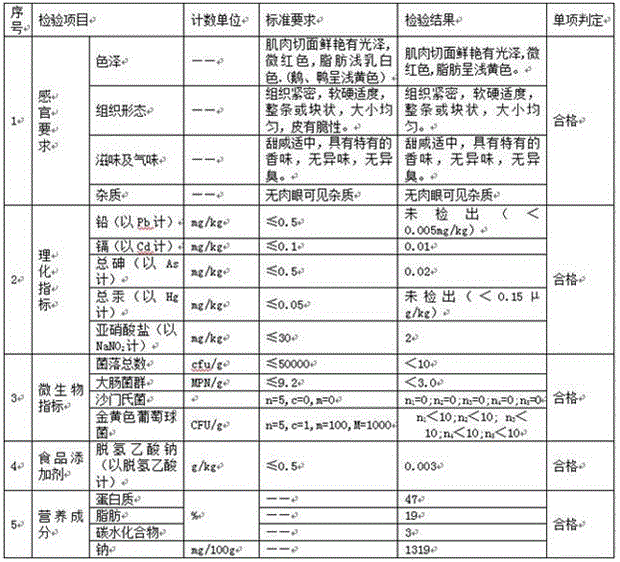

Image

Examples

specific Embodiment approach

[0031] The present invention provides a specific implementation method of a method for making roasted duck neck with cured meat: the method includes the following steps:

[0032] (1) Raw material selection: Choose fresh frozen duck necks that have passed the inspection and have been divided into bags or plates. It is best to choose the duck necks that have been de-stabbed. The weight of each duck neck is 135g, and the duck neck has no skin and no blood. , no breakage, no sundries and complete shape;

[0033] (2) Thawing and cleaning: Put the duck neck of the raw material into the thawing tank for bubbling and thawing, clean the surface of the duck neck, and control the temperature of the center of the raw material at 6°C after thawing;

[0034] (3) Drain: Drain for more than 30 minutes after thawing and cleaning, or drain through a vibrating drainer, and the ambient temperature for draining is 3°C;

[0035] (4) Weigh the ingredients: weigh after draining, and mix the ingredie...

Embodiment 2

[0058] The present invention provides a specific implementation method of a method for making roasted duck neck with cured meat: the following steps are included:

[0059](1) Raw material selection: Choose fresh frozen duck necks that have passed the inspection and have been divided into bags or plates. It is best to choose the duck necks that have been de-stabbed. The weight of each duck neck is 135g, and the duck neck has no skin and no blood. , no breakage, no sundries and complete shape;

[0060] (2) Thawing and cleaning: Put the duck neck of the raw material into the thawing tank for bubbling and thawing, clean the surface of the duck neck, and control the temperature of the center of the raw material at 6°C after thawing;

[0061] (3) Drain: Drain for more than 30 minutes after thawing and cleaning, or drain through a vibrating drainer, and the ambient temperature for draining is 3°C;

[0062] (4) Weigh the ingredients: weigh after draining, and mix the ingredients acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com