Degreasing device for degreasing tank

A technology of degreasing tank and oil inlet channel, which is applied in the direction of grease/oily substance/floating matter removal device, water pollutants, liquid separation, etc. It can solve the problems of production quality that cannot be ignored, large liquid level fluctuations, low oil content, etc. problem, to achieve the effect of increasing the extraction effect, no loss of things, and small relaxation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

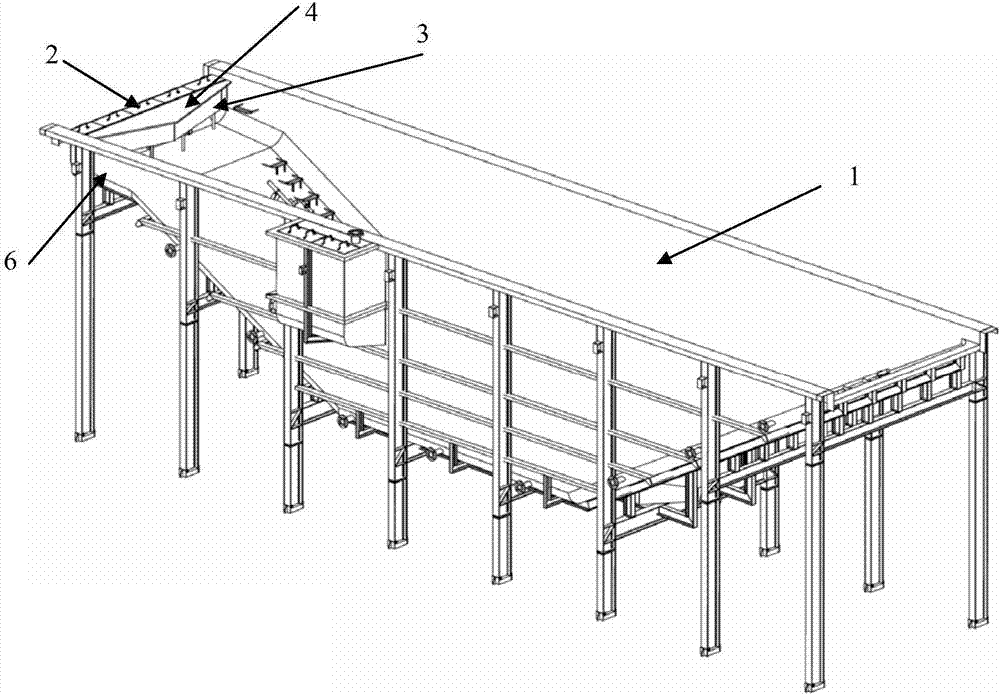

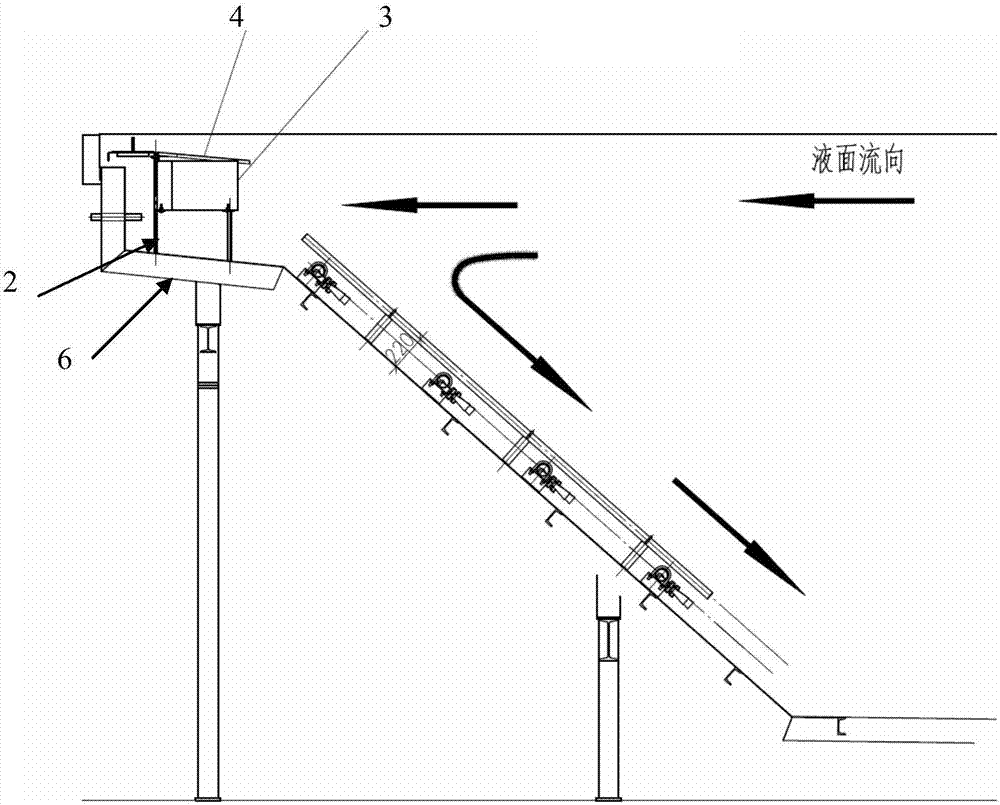

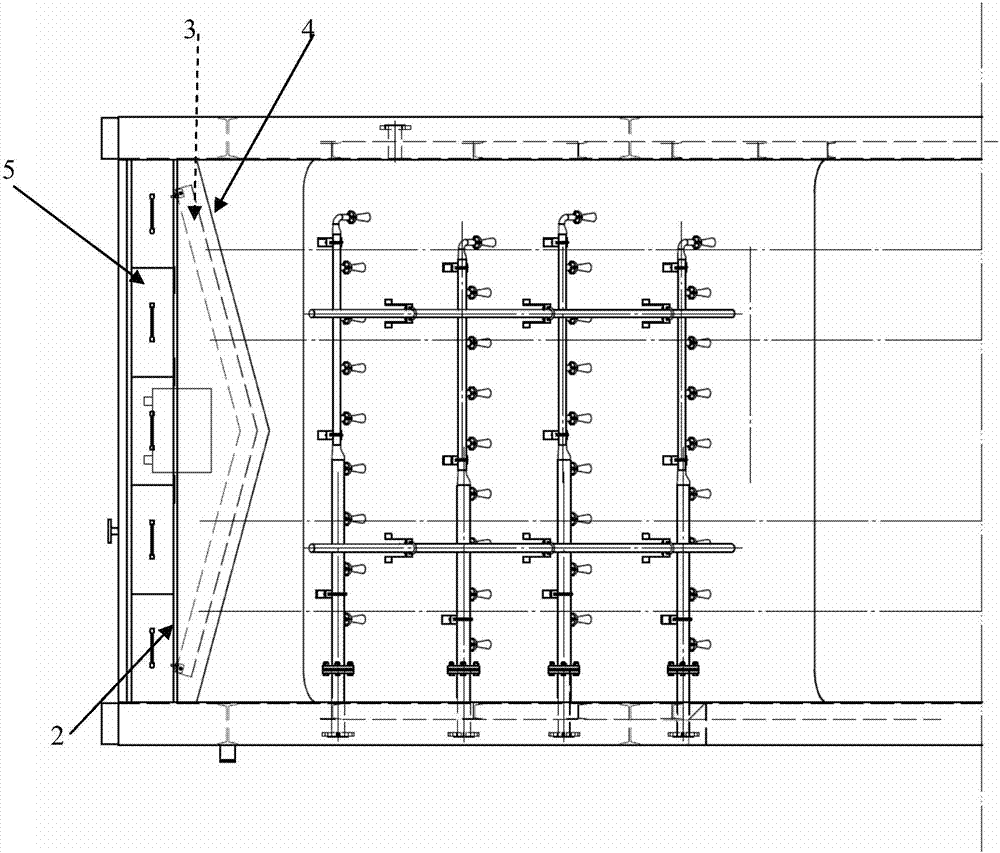

[0025] Such as Figure 1-3 As shown, the front part of the left end plate of the degreasing tank 1 of the present invention is provided with a longitudinal partition 2 to form an isolation area where liquid cannot directly enter relative to the space of the degreasing tank on the right side. Shaped or corner-shaped splitter plate 3 protruding to the right, the upper part of the splitter plate is higher than the predetermined height of the liquid level, generally 4-8cm higher than the liquid level, and the front and rear ends of the splitter plate are kept in contact with the side wall of the degreasing tank. The oil passage, the longitudinal partition and the oil inlet passage are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com