Solid-liquid separating device with automatic cleaning

A solid-liquid separation and automatic cleaning technology, which is applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of complexity, filtration solid slag can not be automatically discharged, heavy workload, etc., to extend the cleaning cycle, The effect of reducing the workload of dismantling and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

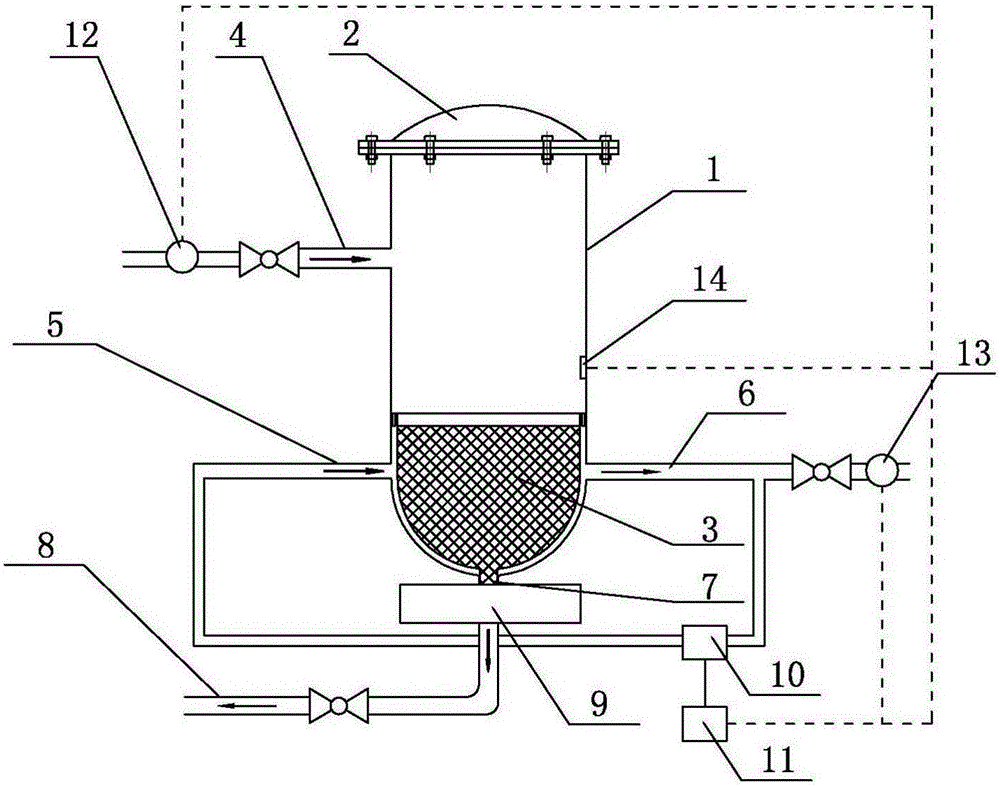

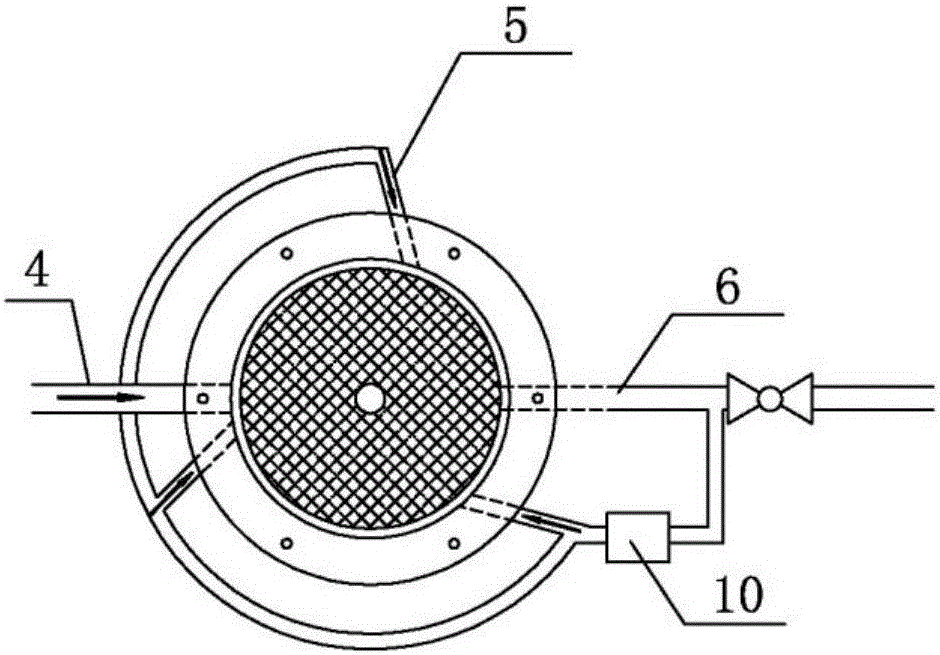

[0018] Such as figure 1 As shown, the solid-liquid separation device with automatic cleaning provided in Embodiment 1 of the present invention includes a separation tank 1, a tank cover 2 is installed on the top of the separation tank 1, and a filter basket 3 is arranged at the bottom of the separation tank 1. The outer periphery of the upper end of the filter basket 3 is attached to the inner wall of the separation tank 1, an annular space is formed between the filter basket 3 and the separation tank 1, and the upper part of the side wall of the separation tank 1 is provided with an input pipe 4 communicating with the inside of the separation tank 1, Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com