Double-barrel reaction kettle for catalytic reaction with porous media

A porous medium, catalytic reaction technology, applied in the field of pressure vessels, can solve the problem of not reaching the optimal speed of production, and achieve the effects of accelerating production, improving production efficiency, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

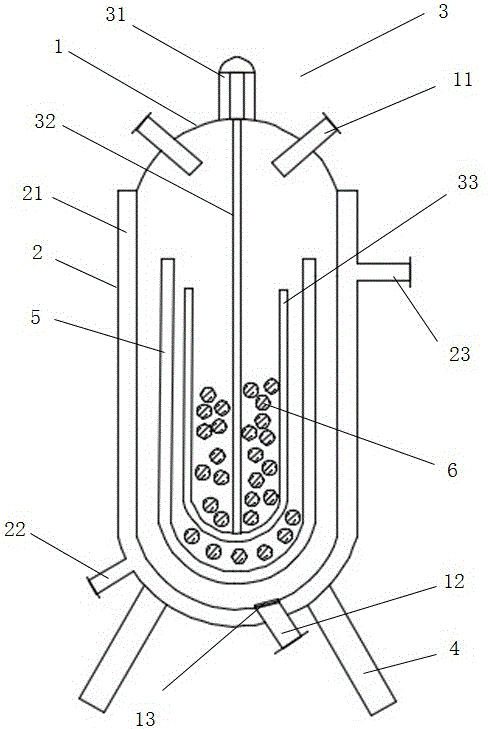

[0019] Embodiment 1: a kind of double barrel reactor of porous medium catalytic reaction, comprises reactor body 1, reactor support 4, reactor jacket 2, reactor sleeve 5, spherical porous medium 6 and stirrer 3, described The reactor body 1 is arranged on the reactor bracket 4; the reactor body 1 top is provided with at least two reactor inlets 11; the reactor body 1 bottom is provided with a reactor outlet 12; The jacket 2 is arranged on the outside of the reactor body 1, and forms an external temperature regulating chamber with the reactor body 1; the upper part of the reactor jacket 2 is provided with a jacket water outlet 23; the reactor jacket 2 The bottom of the jacket is provided with a jacket water inlet 22; the agitator 3 includes a servo motor 31, a stirring shaft 32 and a stirring paddle 33; the servo motor 31 is arranged on the top of the reactor body 1; The centerline of the body 1 is set inside the reactor body 1 and is connected to the servo motor 31; the stirri...

Embodiment 2

[0020] Embodiment 2: a kind of double barrel reactor of porous media catalytic reaction, comprises reactor body 1, reactor support 4, reactor jacket 2, reactor sleeve 5, spherical porous medium 6 and stirrer 3, described The reactor body 1 is arranged on the reactor bracket 4; the reactor body 1 top is provided with at least two reactor inlets 11; the reactor body 1 bottom is provided with a reactor outlet 12; The jacket 2 is arranged on the outside of the reactor body 1, and forms an external temperature regulating chamber with the reactor body 1; the upper part of the reactor jacket 2 is provided with a jacket water outlet 23; the reactor jacket 2 The bottom of the jacket is provided with a jacket water inlet 22; the agitator 3 includes a servo motor 31, a stirring shaft 32 and a stirring paddle 33; the servo motor 31 is arranged on the top of the reactor body 1; The centerline of the body 1 is set inside the reactor body 1 and is connected to the servo motor 31; the stirrin...

Embodiment 3

[0021] Embodiment 3: a kind of double barrel reactor of porous medium catalytic reaction, comprises reactor body 1, reactor support 4, reactor jacket 2, reactor sleeve 5, spherical porous medium 6 and stirrer 3, described The reactor body 1 is arranged on the reactor bracket 4; the reactor body 1 top is provided with at least two reactor inlets 11; the reactor body 1 bottom is provided with a reactor outlet 12; The jacket 2 is arranged on the outside of the reactor body 1, and forms an external temperature regulating chamber with the reactor body 1; the upper part of the reactor jacket 2 is provided with a jacket water outlet 23; the reactor jacket 2 The bottom of the jacket is provided with a jacket water inlet 22; the agitator 3 includes a servo motor 31, a stirring shaft 32 and a stirring paddle 33; the servo motor 31 is arranged on the top of the reactor body 1; The centerline of the body 1 is set inside the reactor body 1 and is connected to the servo motor 31; the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com