Composite structural component and application thereof

A composite material component and composite material technology, applied in the field of composite material structural parts, can solve the problems of low compressive and tensile strength, poor torsion resistance, poor thermal stability, etc., achieve simple manufacturing process, improve bending resistance and resistance Torsional performance, the effect of adapting to thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

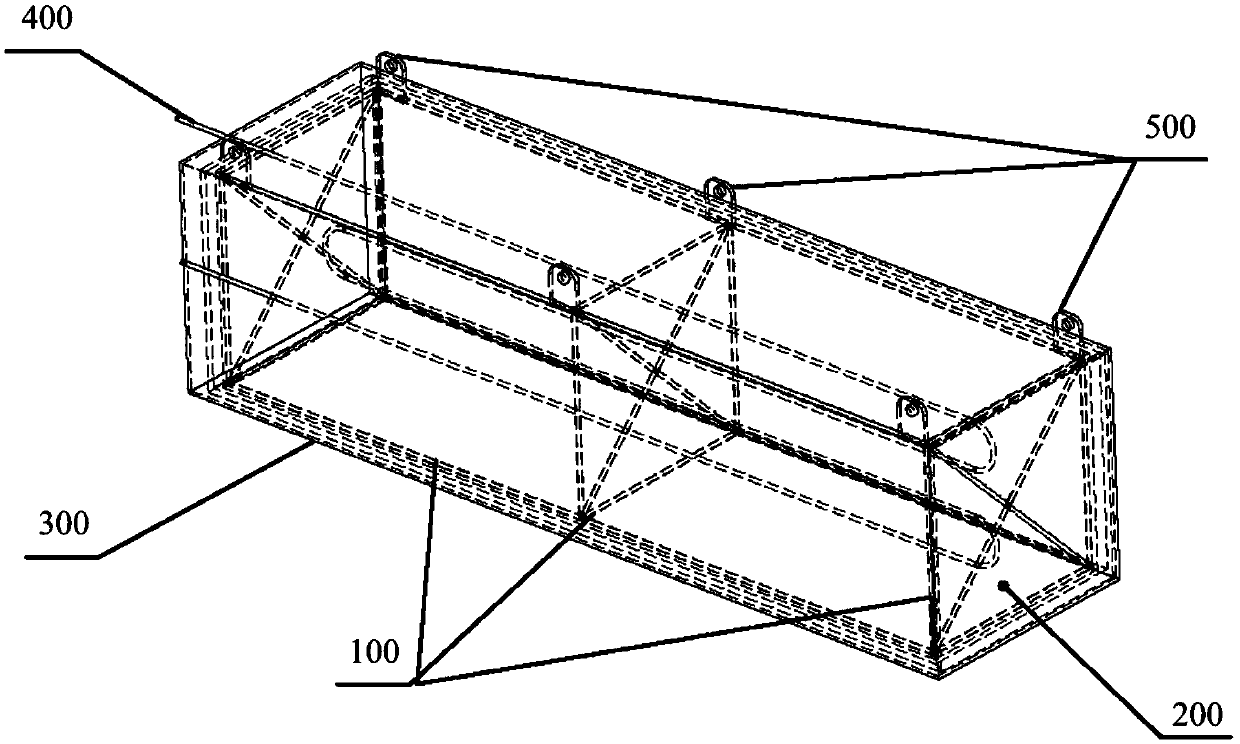

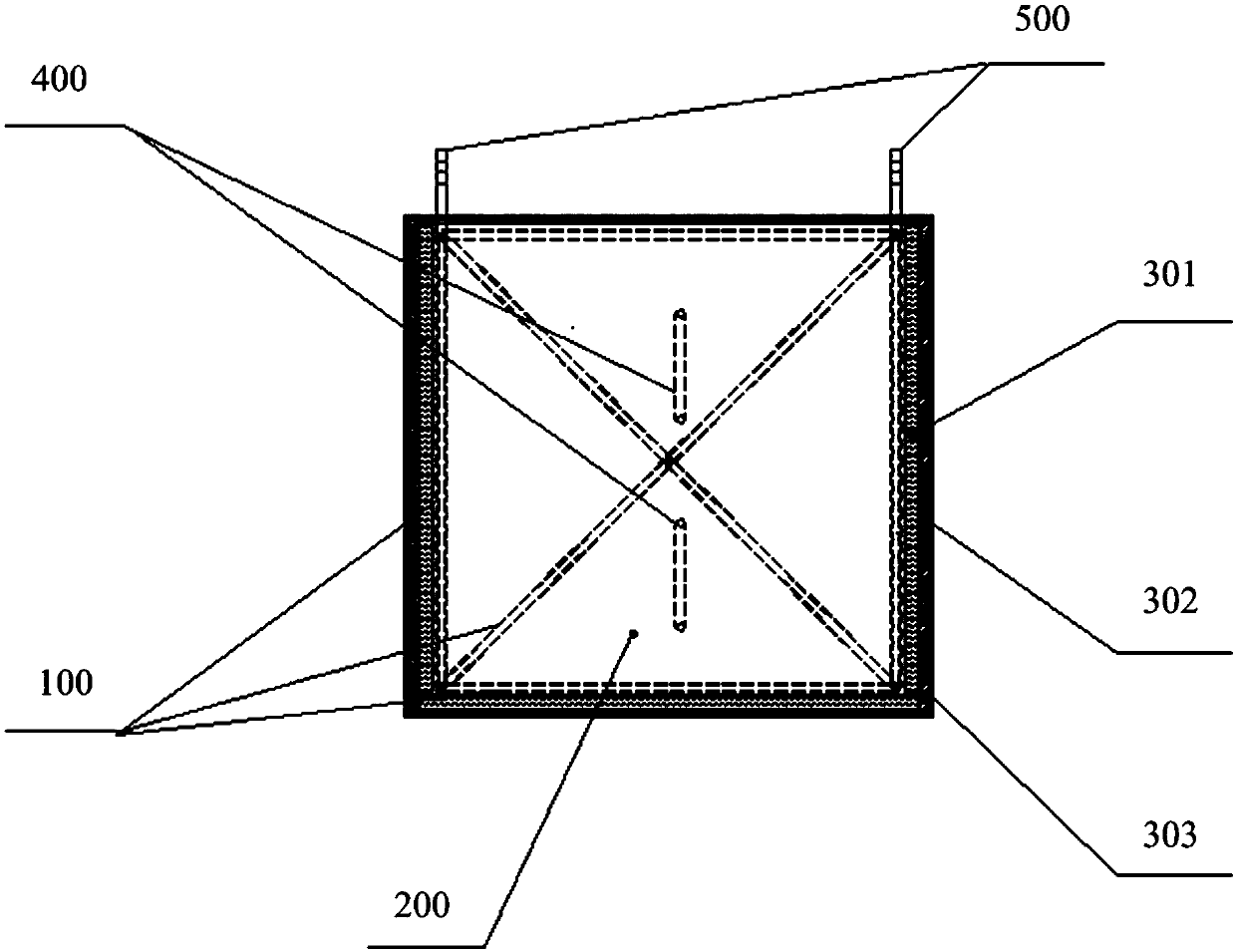

[0043] A composite material structure, including a space truss 100, a bonding material 200 and a fiber cloth 300.

[0044] The space truss 100 is a ball-jointed steel structure, which is preset as a fixed hollow cuboid structure. The coupling material 200 fills the interior of the hollow cuboid structure formed by the space truss 100 , and a hollow heat-conducting member is fixed in the coupling material 200 400, that is, a heat conduction coil containing temperature control components and temperature sensors, so that the temperature of the structure can be monitored in real time during the preparation and use of the structure, and the structure can be heated or cooled by passing through the thermal fluid to reduce the thermal stress of the structure or thermal deformation.

[0045] One side of the cuboid structure is provided with a fixing point 500 for fixing the composite material member, the outer surface of this side is covered with a layer of fiber cloth 300, the surface...

Embodiment 2

[0051] A composite material structure, including a space truss 100, a bonding material 200 and a fiber cloth 300.

[0052] The space truss 100 is a ball-jointed steel structure, which is preset as a fixed hollow cuboid structure. The coupling material 200 fills the interior of the hollow cuboid structure formed by the space truss 100 , and a hollow heat-conducting member is fixed in the coupling material 200 400, that is, a heat conduction coil containing temperature control components and temperature sensors, so that the temperature of the structure can be monitored in real time during the preparation and use of the structure, and the structure can be heated or cooled by passing through the thermal fluid to reduce the thermal stress of the structure or thermal deformation.

[0053] One side of the cuboid structure is provided with a fixing point 500 for fixing the composite material member, the outer surface of this side is covered with a layer of fiber cloth 300, the surface...

Embodiment 3

[0059] A composite material structure, including a space truss 100, a bonding material 200 and a fiber cloth 300.

[0060] The space truss 100 is a ball-jointed steel structure, which is preset as a fixed hollow cuboid structure. The coupling material 200 fills the interior of the hollow cuboid structure formed by the space truss 100 , and a hollow heat-conducting member is fixed in the coupling material 200 400, that is, a heat conduction coil containing temperature control components and temperature sensors, so that the temperature of the structure can be monitored in real time during the preparation and use of the structure, and the structure can be heated or cooled by passing through the thermal fluid to reduce the thermal stress of the structure or thermal deformation.

[0061] One side of the cuboid structure is provided with a fixing point 500 for fixing the composite material member, the outer surface of this side is covered with a layer of fiber cloth 300, the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com