Dry and wet livestock manure treatment device

A technology for livestock and poultry manure and treatment equipment, which is applied in fertilization equipment, applications, organic fertilizers, etc. It can solve the problems of inactivation of fermentation bacteria, affect the fermentation effect, and low fermentation temperature, so as to avoid the inactivation of fermentation bacteria and improve the quality of fermentation , good fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

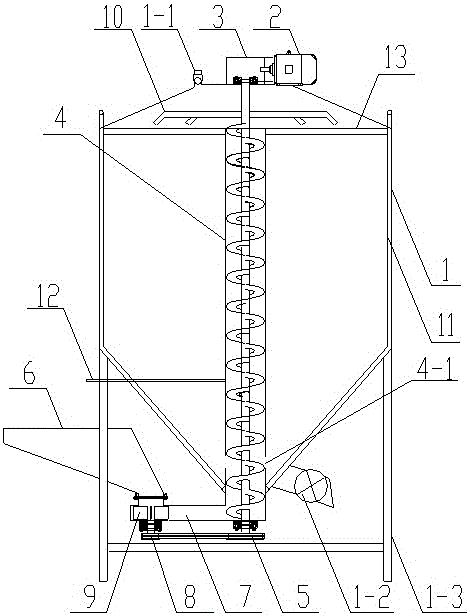

[0013] like figure 1 As shown, the present invention includes: a fermentation tower body 1, a motor 2, a reducer 3, a feeding auger 4, an A pulley 5, a hopper 6, a material channel 7, a B pulley 8, a paddle 9, and a lever 10 1, a group of aeration pipes 11 and temperature sensing sleeves 12, the fermentation tower body 1 is inverted conical, the fermentation tower body 1 is fixed by supports 1-3, and the top and bottom of the fermentation tower body 1 are respectively provided with exhaust Port 1-1 and discharge port 1-2, the exhaust port 1-1 is provided with a one-way valve, the motor 2 and the reducer 3 are respectively located at the top of the fermentation tower body 1, the power output shaft of the motor 2 is connected to the The power input shaft of the speed reducer 3 is connected by transmission. The feed turning and throwing auger 4 is located in the fermentation tower body 1, and the bottom extends to the outside of the fermentation tower body 1. The power output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com