Boring cutter installing shaft, boring assembly and boring mill

A technology for installing shafts and boring tools, which is applied in boring/drilling, accessories of toolholders, drilling/drilling equipment, etc. Meet the requirements, poor rigidity and other problems, to achieve the effects of not being easy to bend and deform, increasing the outer diameter, and improving the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

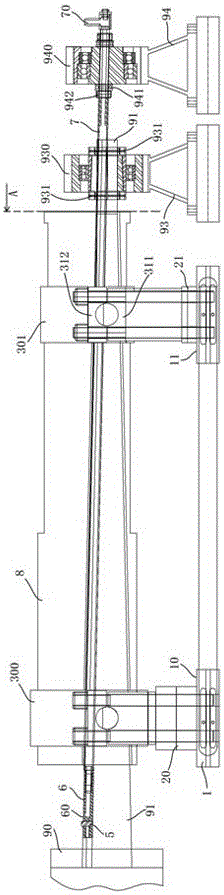

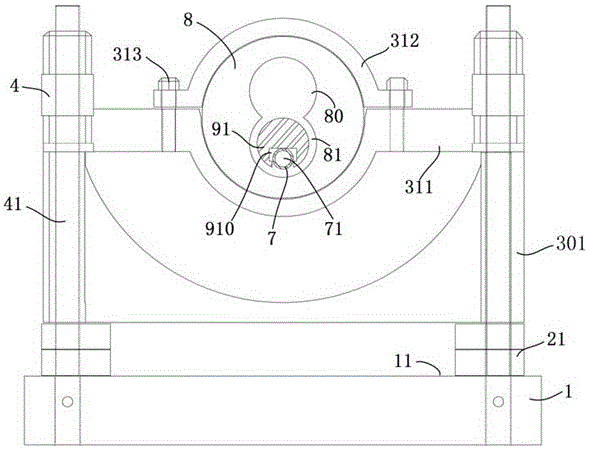

[0022] The embodiment of boring machine of the present invention: mainly be used in processing cone double barrel, as figure 1 , 3 As shown, it includes a frame on which a workpiece mounting frame for installing workpieces to be processed is arranged. The workpiece mounting frame includes a base 1. The base 1 is used for fixed connection with the machine tool slide plate and can move forward and backward with the machine tool slide plate. The base 1 is respectively provided with a front support surface 10 and a rear support surface 11. The workpiece mount also includes a front mounting seat 300 corresponding to the front support surface 10 and a rear mounting seat 301 corresponding to the rear support surface 11. The front mounting seat 300 is used to fix the large diameter section of the front end of the workpiece, and the rear mounting seat 301 is used to fix the workpiece. The small diameter section of the rear end of machine barrel workpiece 8.

[0023] The workpiece mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com