A torque optimization distribution control method for distributed drive electric vehicles

A technology for electric vehicles and optimized distribution, applied in electric vehicles, control drives, control devices, etc., can solve the problems of poor stability and tire wear of electric vehicles, and achieve the effect of ensuring stability and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

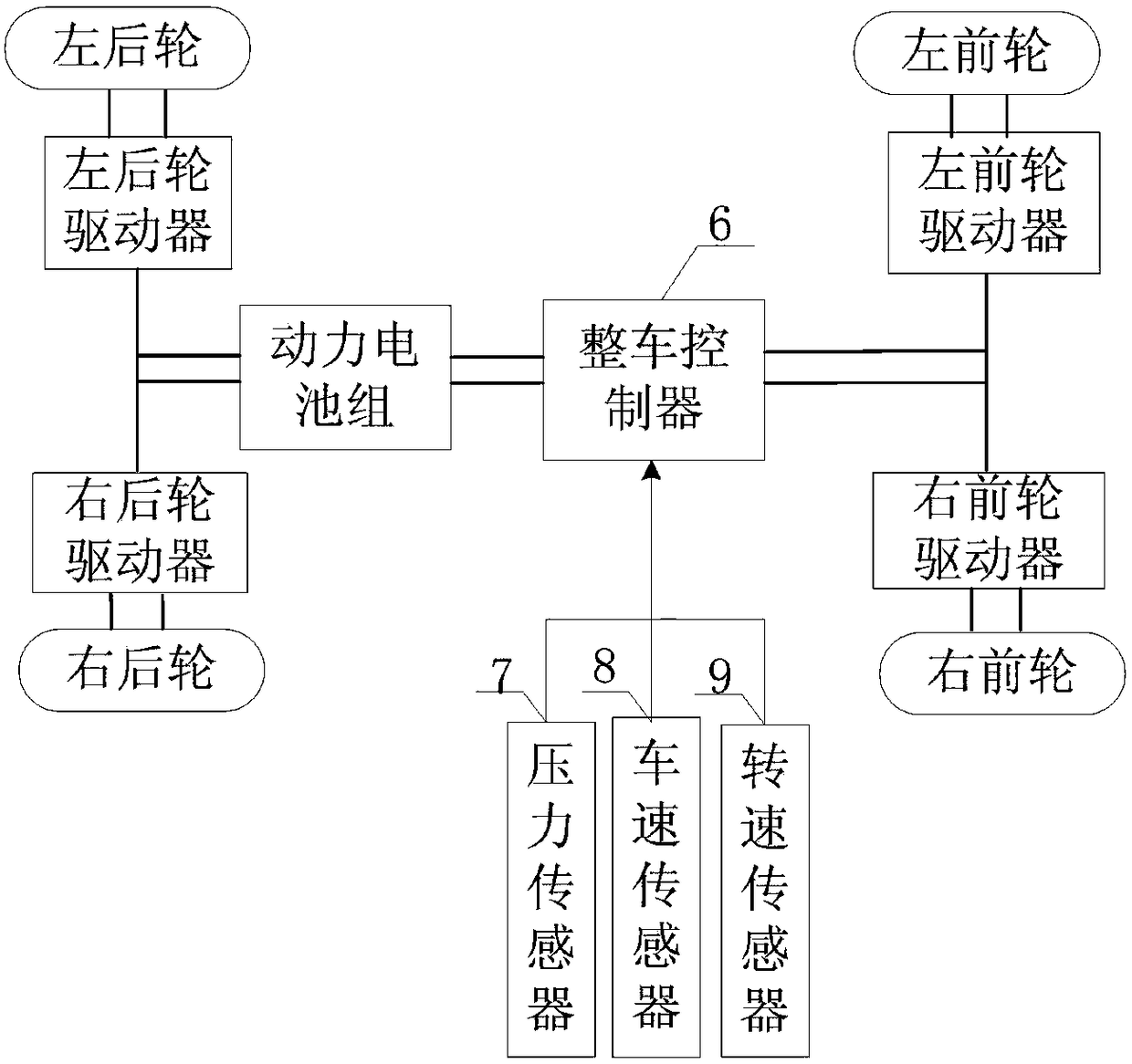

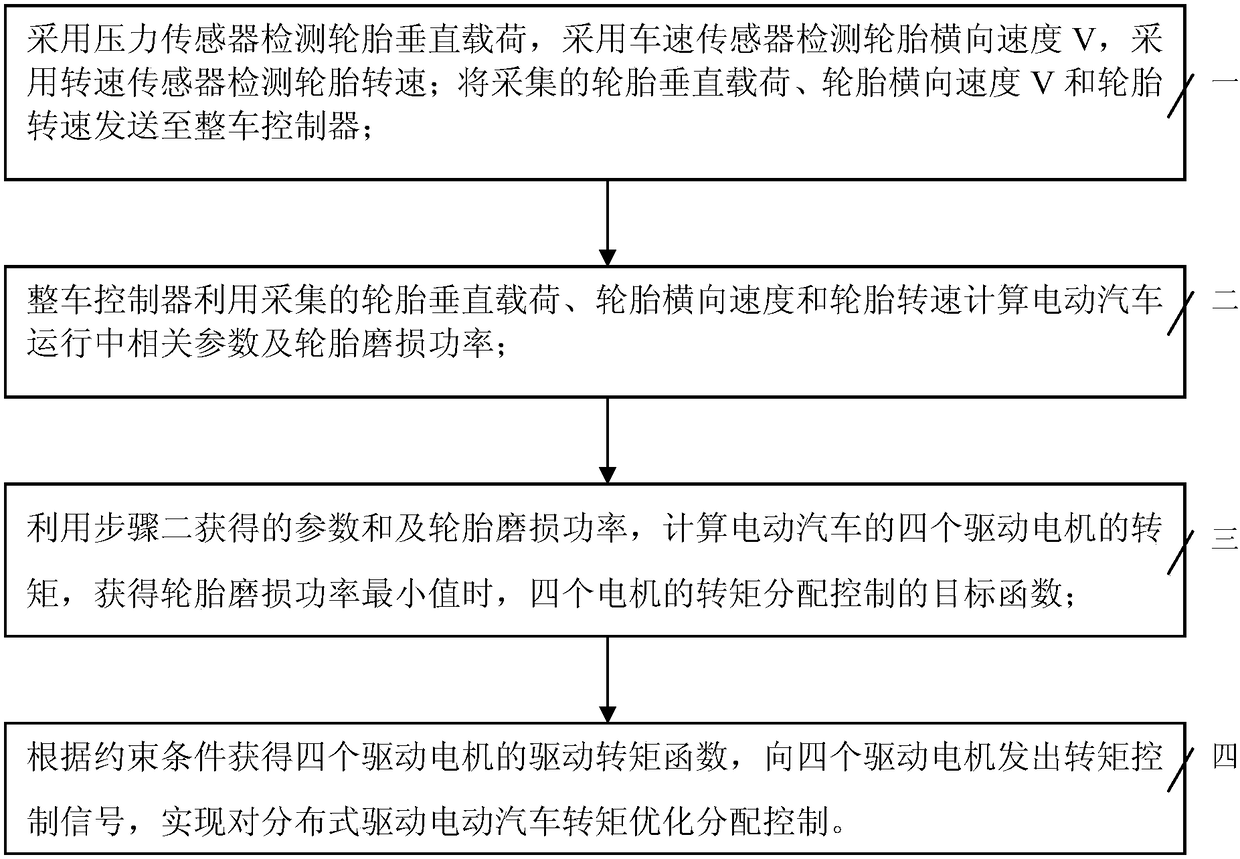

[0013] Specific implementation mode 1. Combination figure 1 Describe this embodiment, a kind of distributed drive electric vehicle torque optimal distribution control method described in this embodiment, the specific steps of this method are:

[0014] Step 1. Use the pressure sensor 7 to detect the tire vertical load, use the vehicle speed sensor 8 to detect the tire lateral velocity, and use the rotational speed sensor 9 to detect the tire rotational speed; send the collected tire vertical load, tire lateral velocity and tire rotational speed to the vehicle controller 6;

[0015] Step 2, the vehicle controller 6 uses the collected tire vertical load, tire lateral velocity and tire rotational speed to calculate the relevant parameters and tire wear work of the electric vehicle during operation;

[0016] The relevant parameters include: the slip rate of each tire of the electric vehicle, the rotational speed of each tire of the electric vehicle, the lateral velocity of each tir...

specific Embodiment approach 2

[0019] Specific embodiment 2. This embodiment is a further description of a distributed drive electric vehicle torque optimization distribution control method described in specific embodiment 1. The slip ratio of each tire of the electric vehicle described in step 2 The method of obtaining is: using the rotation speed sensor to detect the tire rotation speed, and the speed sensor to detect the tire lateral speed. The specific method is to use the formula:

[0020]

[0021] obtained, where s is the slip rate, ω is the tire rotational speed, R is the effective rolling radius of the tire, and V is the longitudinal velocity of the tire.

specific Embodiment approach 3

[0022] Specific embodiment 3. This embodiment is a further description of a distributed drive electric vehicle torque optimization distribution control method described in specific embodiment 1. The friction suffered by each tire in the longitudinal direction described in step 2 The specific method of force is through the formula:

[0023] f x =K·F z s (2)

[0024] obtained, where F x is the frictional force on the tire in the longitudinal direction, F z is the vertical load borne by the tire, and K is the friction coefficient of the tire material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com