Plastic packaging part capable of being turned over

A technology of components and flip brackets, which is applied in the directions of external support, packaging sealing/fastening, transportation packaging, etc., which can solve the problems of insufficient flexibility and operator inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

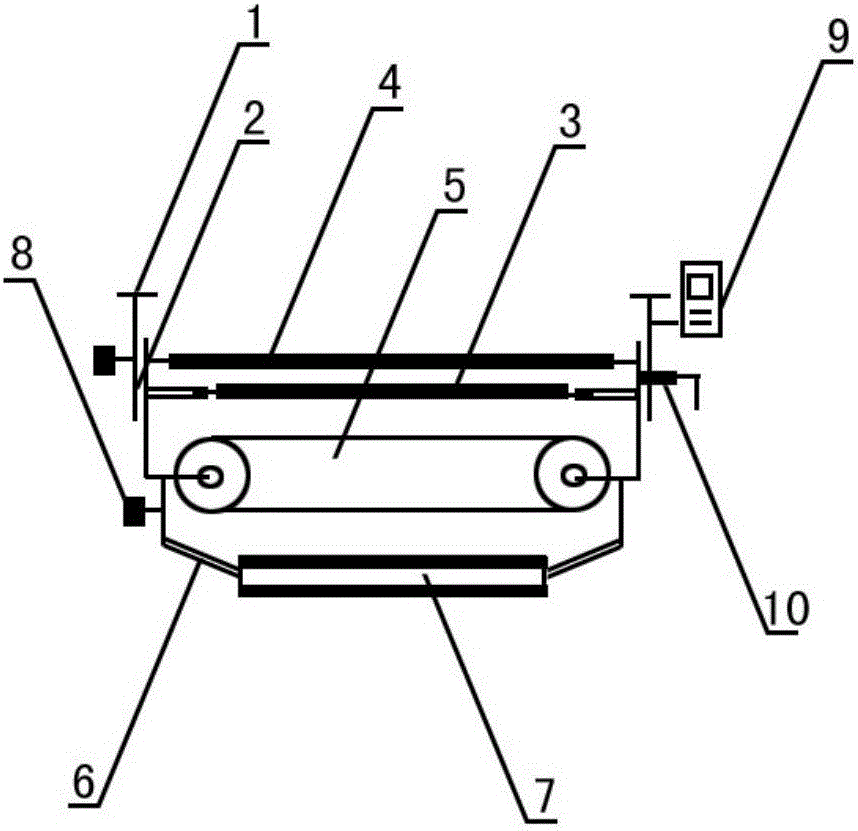

[0012] Embodiment: as shown in the accompanying drawing. A reversible plastic sealing part, comprising a frame body (1), the upper end of the frame body (1) is provided with a width adjustment frame (2), a front heating roller (3), a rear heating roller (4), and a cylindrical The guide roller device (5) is connected with the slot-type heating device (7) through the overturning bracket (6). During operation, the bag mouth is stuck on the heating device (7) for the first plastic sealing and then flipped to the upper end for the second one. For plastic sealing operation, the plastic sealing interval can be adjusted artificially according to the rotation range.

[0013] A reversible plastic sealing part is provided with two prompting devices (8), which give corresponding prompts when the plastic parts are in different step-by-step states.

[0014] A reversible plastic-encapsulated component, which prompts information in the form of sound or LED light display.

[0015] A reversib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com