A hoisting tool for a large-diameter gate valve plate used in a nuclear power plant

A hoisting tool and large-diameter technology, which is applied in the field of hoisting tools for large-diameter gate valve plates used in nuclear power plants, can solve the problems of large space occupied by the hoisting device, and achieve the effects of reducing workload, wide application range, and reliable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

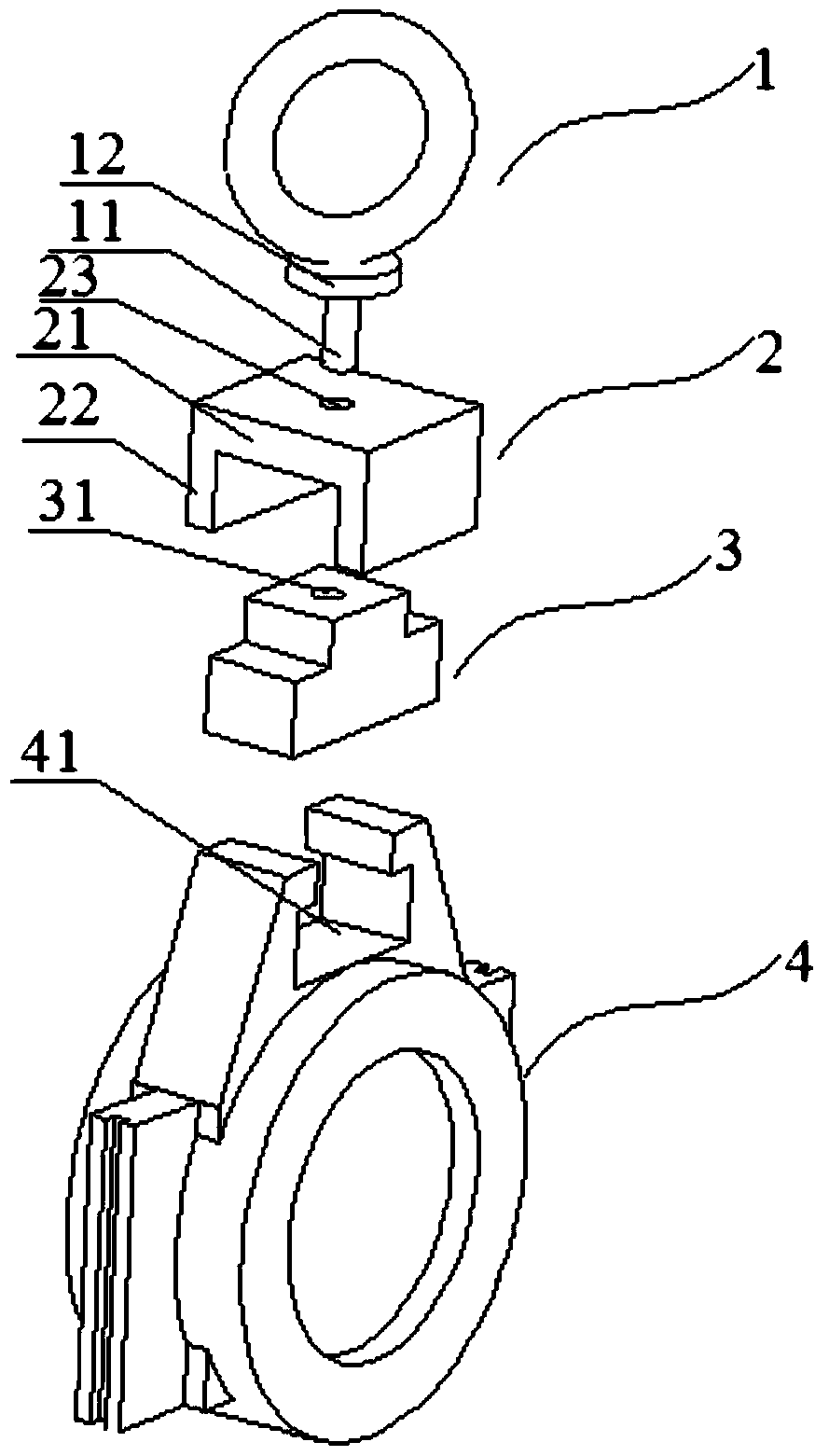

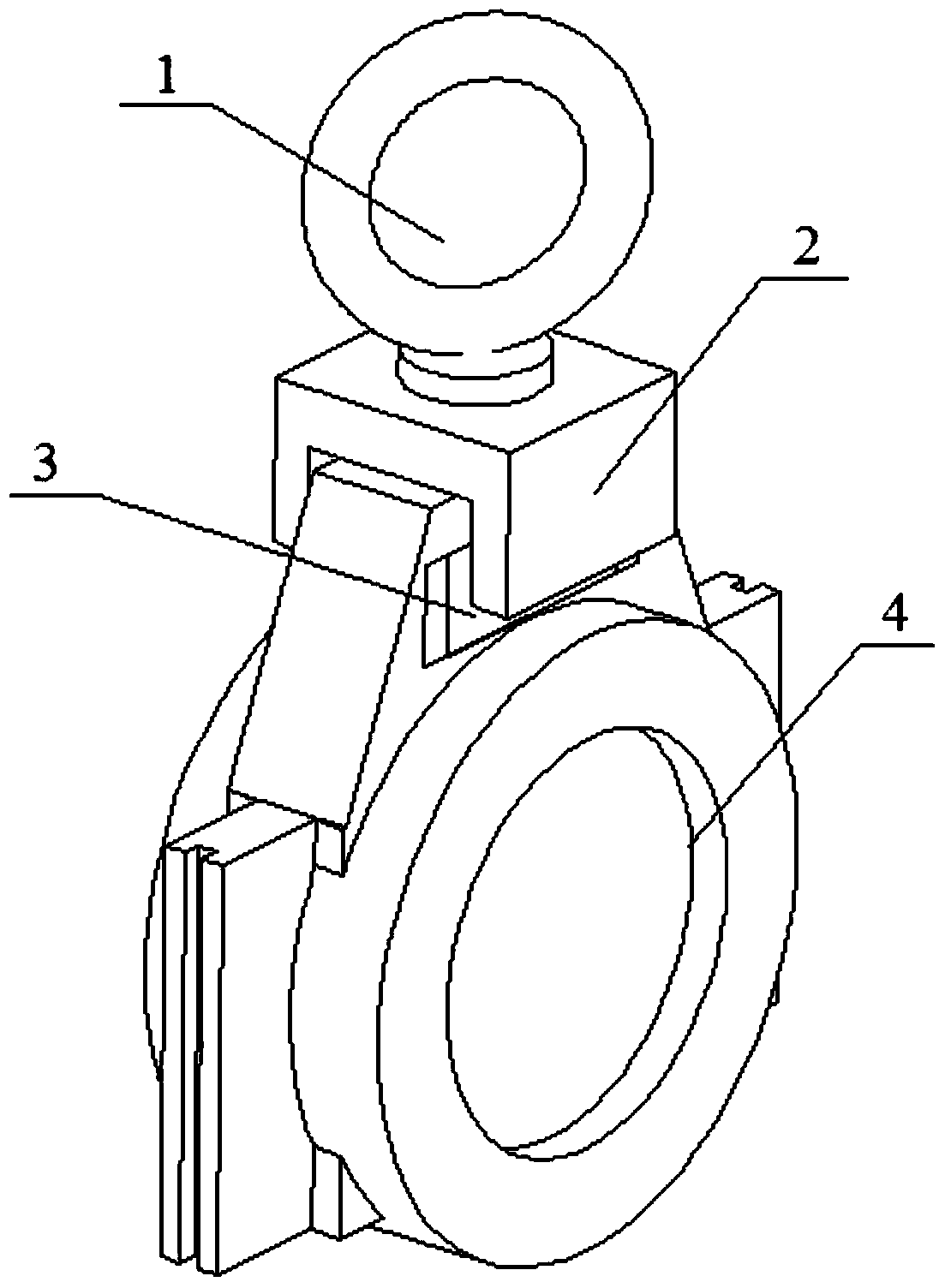

[0025] Such as figure 1 , figure 2 As shown, a large-diameter gate valve plate hoisting tool for nuclear power plants, wherein the upper end of the valve plate 4 is provided with a T-shaped groove 41, the hoisting tool includes a lifting ring 1, a frame block 2 and a T-shaped block 3, when hoisting the valve plate 4, The T-shaped block 3 is inserted into the T-shaped groove 41, the frame-shaped block 2 is fastened on the upper end of the valve plate 4, and the T-shaped block 3 is clamped inside, and the lower end of the suspension ring 1 is connected with a bolt 11, and the bolt 11 is from top to bottom. After passing through the frame block 2, it is screwed on the T-shaped block 3. Wherein, the top surface of the valve plate 4 is a horizontal plane, and the upper end of the T-shaped groove 41 extends to the top surface of the valve plate 4 . The structure and size of the block 3 and the T-shaped slot 41 are the same. When the T-shaped block 3 is clamped in the T-shaped slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com