Externally arranged, compacted and grouted Larsen steel sheet pile composite retaining structure and use method thereof

A Larsen steel sheet pile and composite support technology, which is applied in sheet pile walls, foundation structure engineering, excavation, etc., can solve the problems of high construction cost, low tensile strength, and large width, so as to ensure safety and stability, improve resistance The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

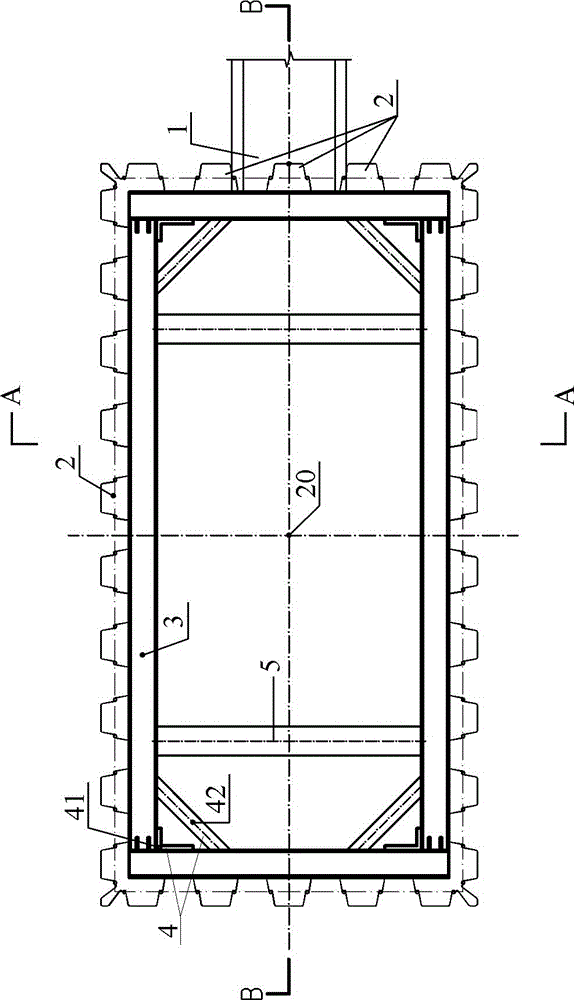

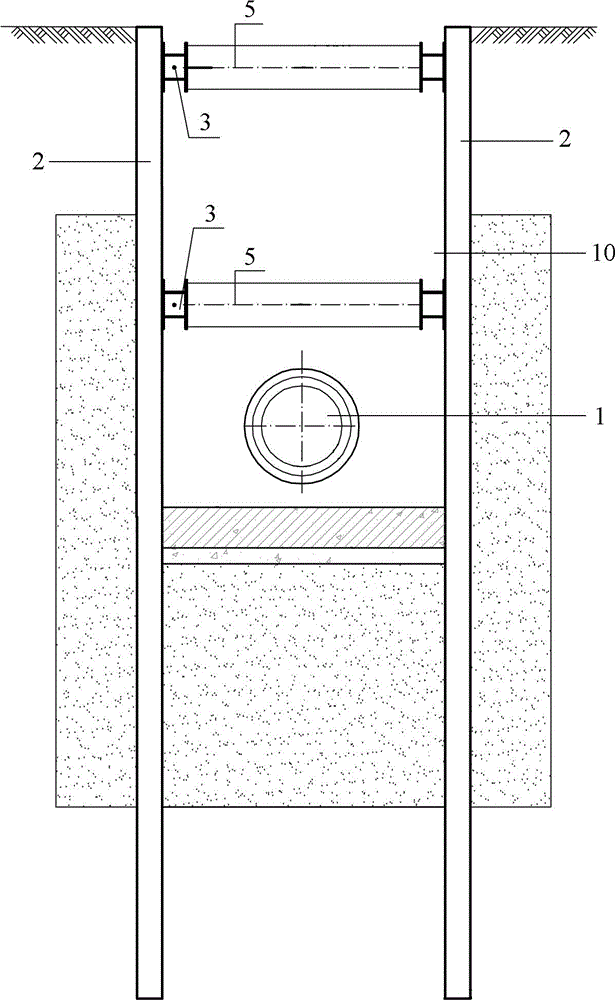

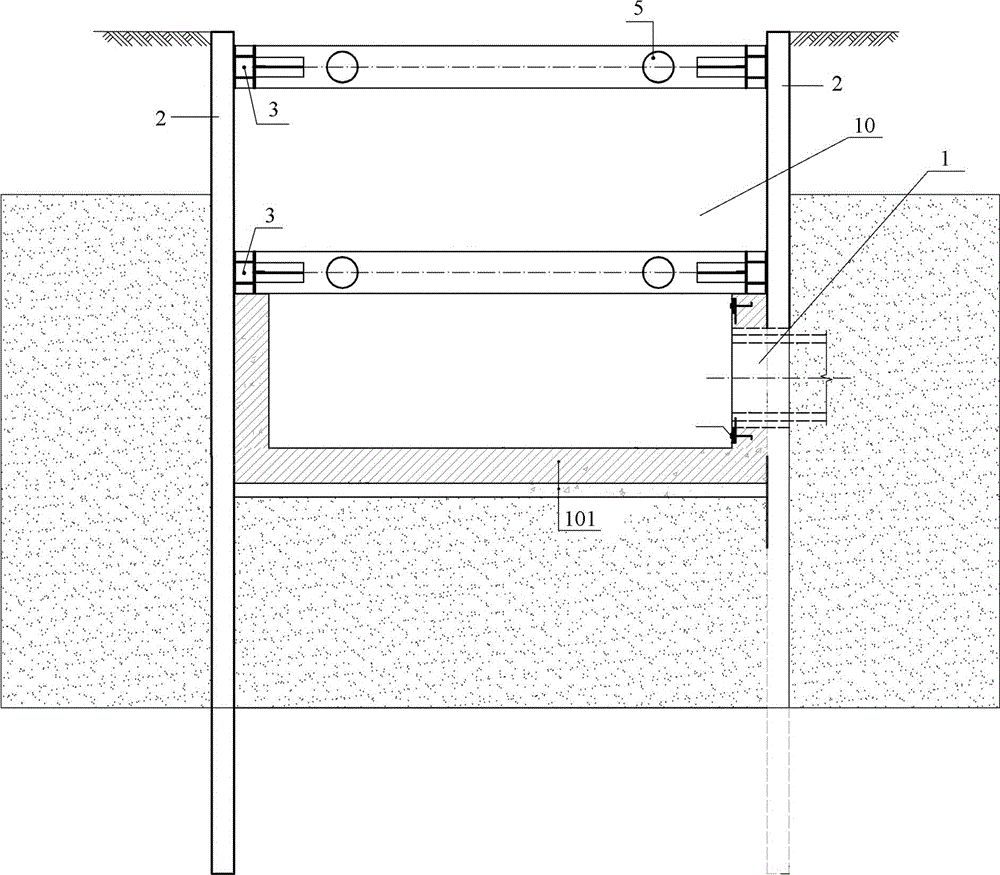

[0036] A Larsen steel sheet pile composite support structure with external compaction grouting, including jacking pipe 1, Larsen pile 2, purlin 3, connector 4 and inner support pipe 5, such as Figure 1 ~ Figure 3 As shown, the specific structure is:

[0037] The jacking pipe 1 is arranged in the foundation pit 10;

[0038] Each Larsen pile 2 is vertically arranged in the foundation pit 10, the bottom of the Larsen pile 2 is inserted into the bottom surface of the foundation pit 10, and the Larsen piles 2 are arranged successively around each inner side wall of the foundation pit 10. The Larsen piles 2 One side of the foundation pit 10 is bonded to the inner side wall;

[0039] The surrounding purlins 3 are horizontally arranged in the foundation pit 10, and each inner wall of the foundation pit 10 is provided with two surrounding purlins 3 in layers from top to bottom, and the surrounding purlins 3 located on the same layer on each inner side wall of the foundation pit 10 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com