Compressor

A compressor and pressure plate technology, which is applied in the field of compressors, can solve problems such as failure, improper fit, and high complexity of balancing structure installation, and achieve the effects of improving the overall dynamic balance, reducing assembly complexity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0027] In order to solve the problems in the prior art that the balance structure is highly complicated to install and easily fails due to improper fit, the present invention provides a compressor.

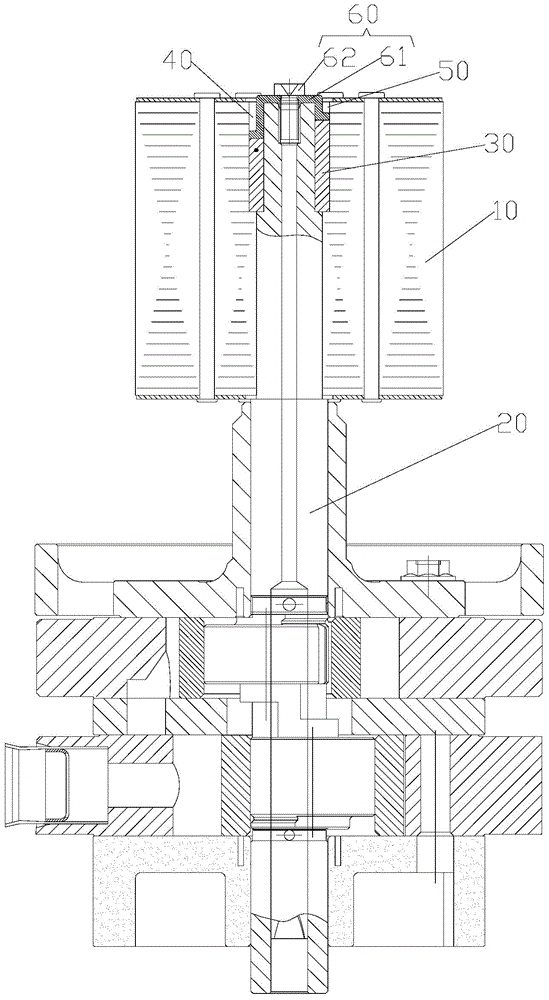

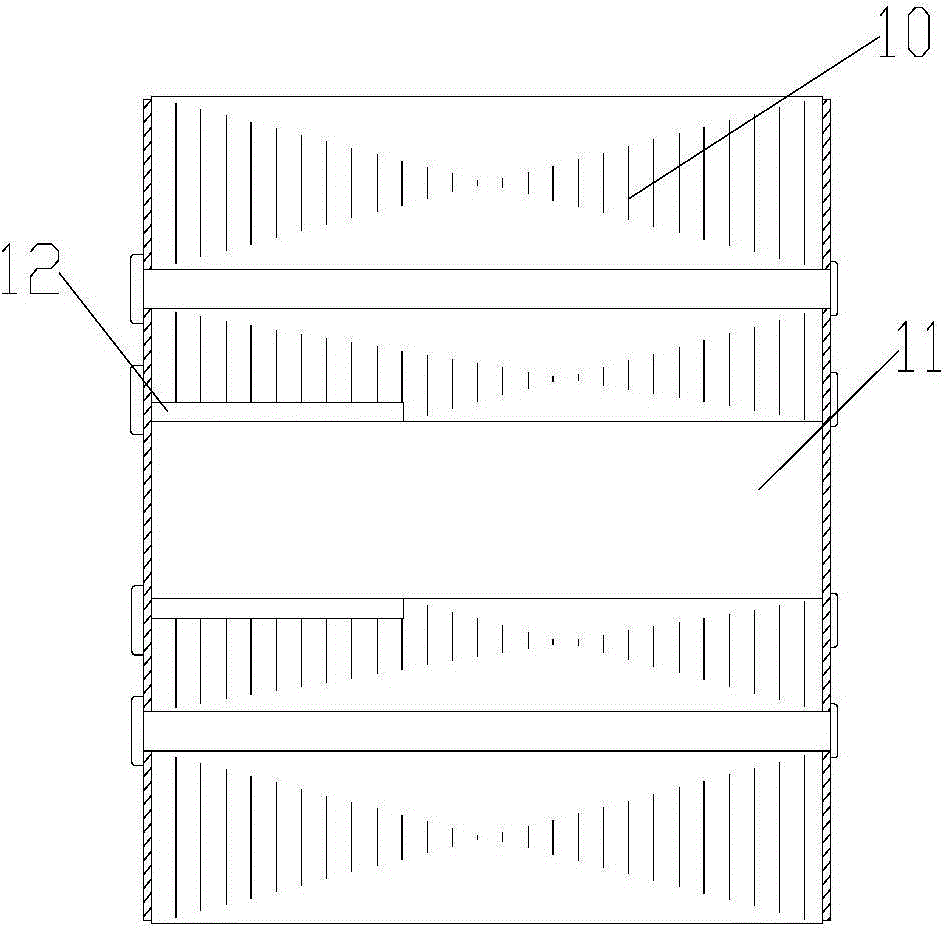

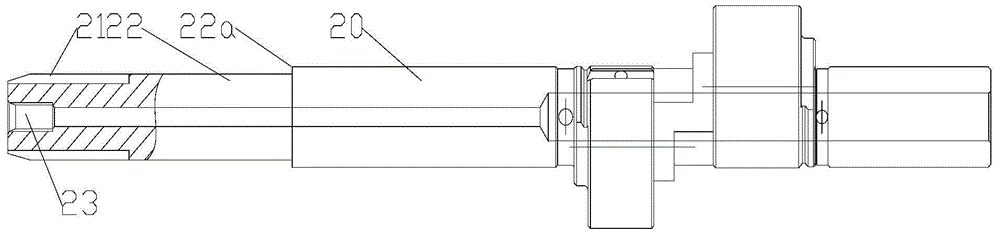

[0028] Such as Figure 1 to Figure 7 As shown, the compressor in the present invention includes a rotor 10, a crankshaft 20 and a connecting key 30. The rotor 10 has a shaft hole 11, and the wall of the shaft hole 11 is provided with a first keyway 12; the crankshaft 20 is penetrated in the shaft hole 11 , the outer peripheral surface of the crankshaft 20 has a second keyway 21 matched with the first keyway 12, the first keyway 12 and the second keyway 21 form a positioning space; the connecting k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com