Water source heat pump loop system

A water source heat pump and loop technology, which is applied in heat pumps, air conditioning systems, heating and ventilation control systems, etc., can solve the problems of resource waste, large power consumption, heat waste, etc., to avoid heat waste, avoid blockage, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

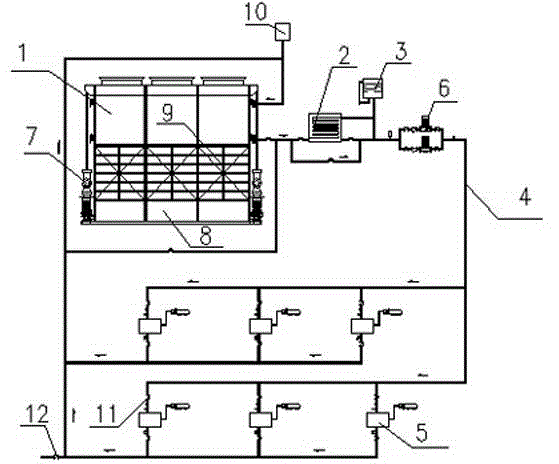

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] A water source heat pump loop system is provided with a cooling tower 1, a heating device 2 and a circulating water tank 3, the heating device 2 is connected next to the cooling tower 1, the heating device 2 and the circulating water tank 3 are connected to each other, and a circulating pipe is arranged around the cooling tower 1 Road 4, the circulation pipeline 4 is connected with the air-conditioning main engine 5, the water pump 6 is arranged behind the circulating water tank 3, a thermometer is arranged between the circulating water tank 3 and the water pump 6, and a control valve is arranged on both sides of the heating device 2, and the control valve is a ball valve. There is a circulation circuit under the device 2, and a control valve is provided on the circulation circuit. There are descaling parts 7 on both sides of the cooling tower 1. The descaling pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com