System and method for measuring gear 3D profile based on line laser scanning

A three-dimensional profile and line laser technology, applied in the field of measurement, can solve problems such as unsatisfactory real-time detection, complex structure of measuring equipment, complex gear shape, etc., and achieve the effects of large variable range of equipment volume, convenient measurement and calculation, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

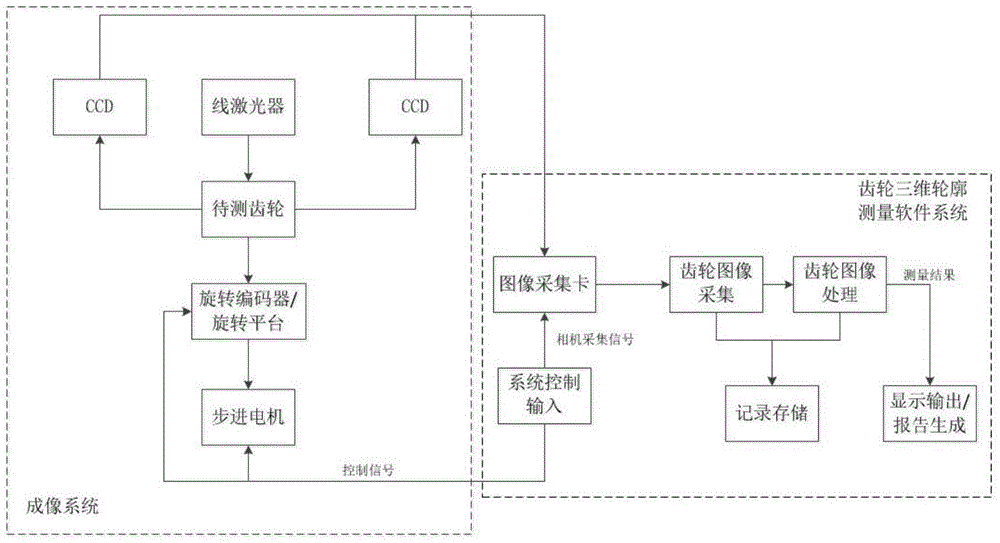

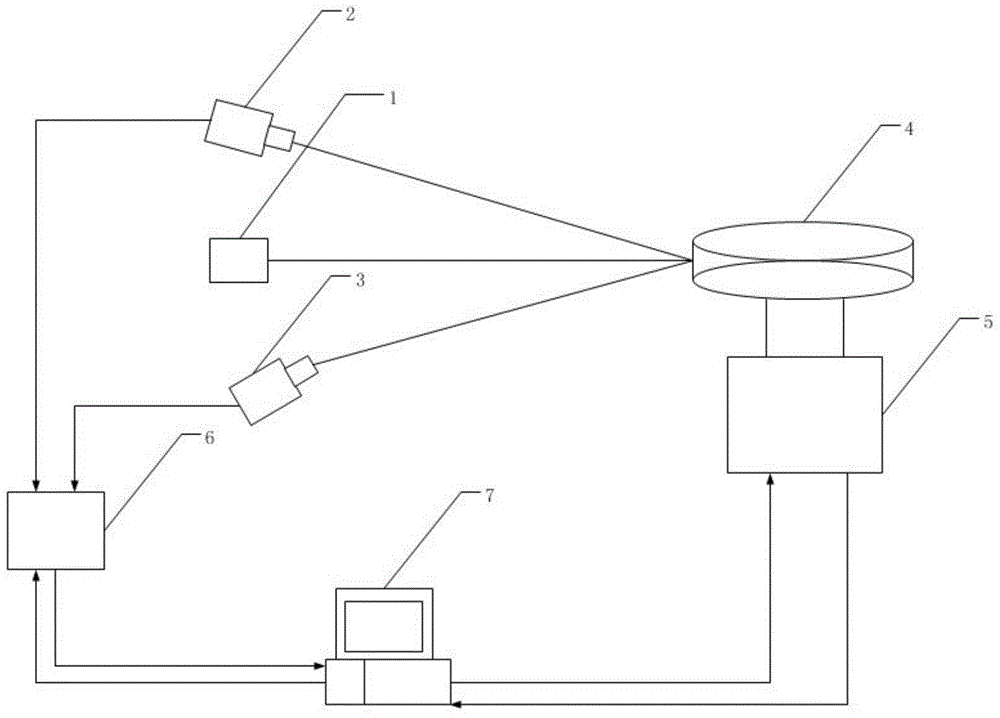

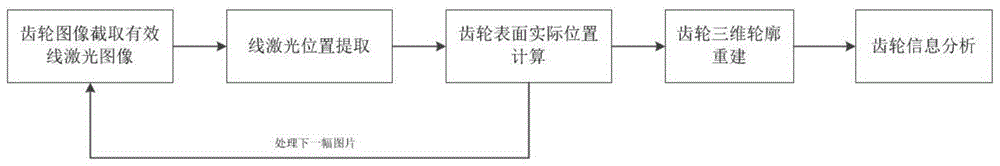

[0021] combine figure 1 , this embodiment discloses a method for detecting a three-dimensional profile of a gear, comprising:

[0022] Gear 3D profile imaging system, gear 3D profile measurement system; among them,

[0023] The gear three-dimensional profile imaging system includes a first CCD2, a second CCD3, a line laser 1, an object stage 5, a rotary encoder, and a stepping motor, and the gear three-dimensional profile measurement system includes an image acquisition card 6 and a PC7. The first CCD2 and the second CCD3 are connected with the image acquisition card 6, and the CCD is connected with the image acquisition card, and the input and output of PC control data are arranged, and the image acquisition card 6, the rotary encoder, and the stepper motor are connected with the PC7 , the PC7 controls the acquisition of the image acquisition card 6, the PC7 controls the opening and closing of the stepping motor, the PC controls the opening and closing of the rotary encoder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com