Current control circuit and electrode water level monitoring device

A technology of current control circuit and control circuit, which is applied in the direction of measuring device, lubrication indicator device, liquid/fluid solid measurement, etc. It can solve the problems of reducing the accuracy of liquid level monitoring, the electrode can not conduct electricity, and the electrode is oxidized and rusted, so as to improve the The effect of monitoring accuracy, ensuring electrical conductivity, and reducing misjudgment of liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

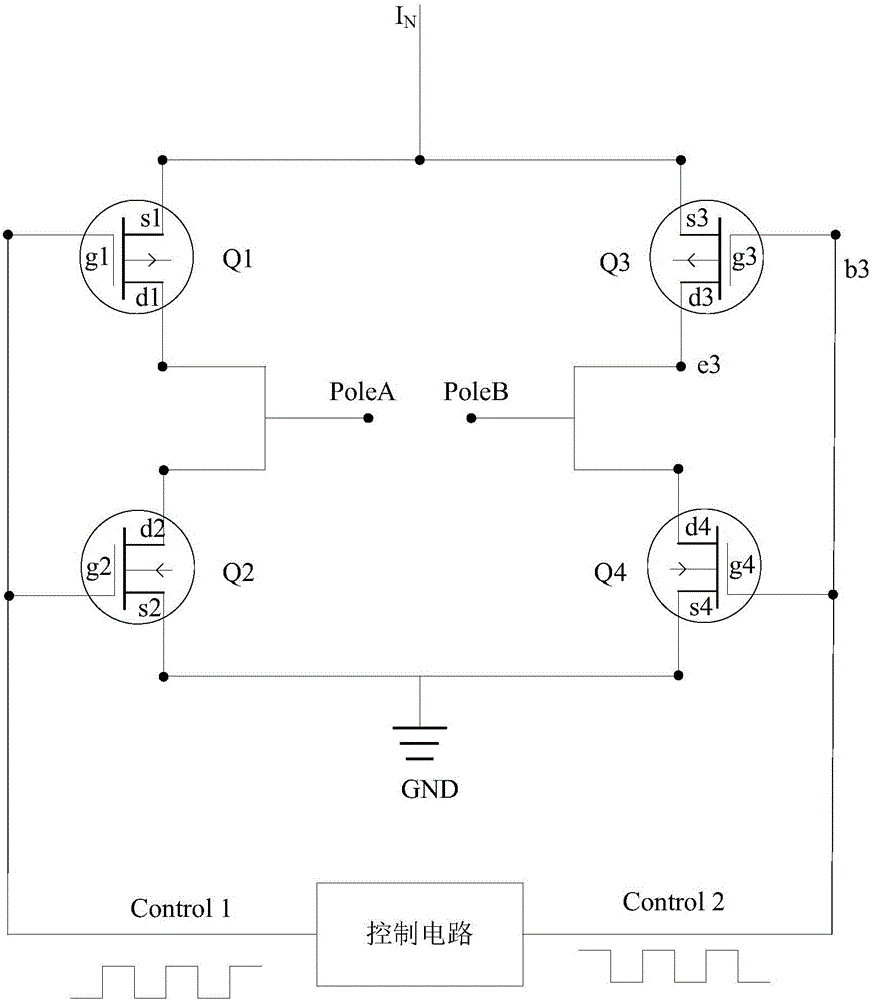

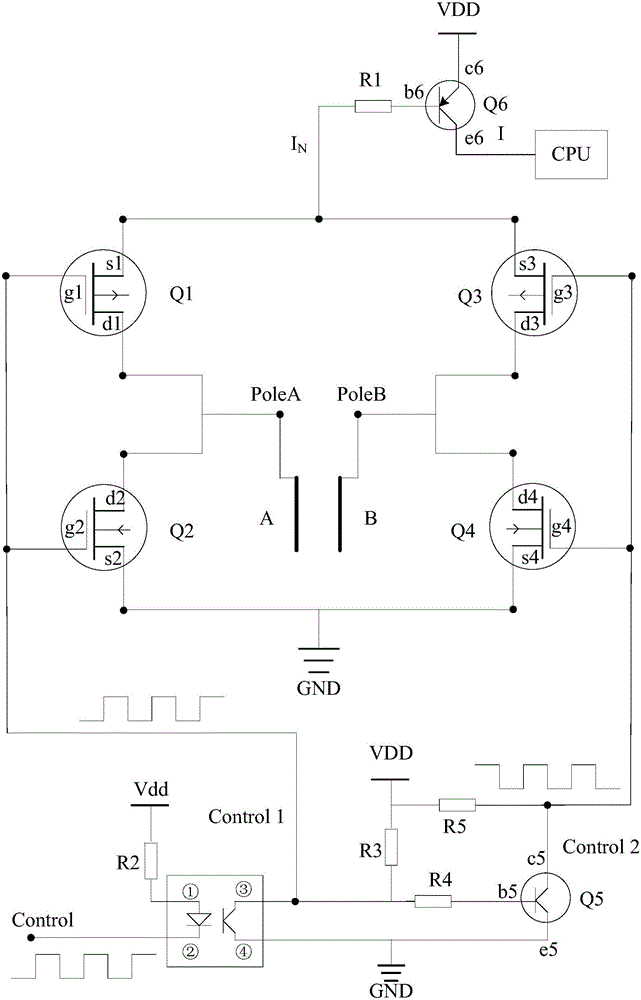

[0016] refer to figure 1 as shown, figure 1 It is a structural schematic diagram of a current control circuit, including: transistors Q1, Q2, Q3 and Q4, and a control circuit;

[0017] The control circuit outputs the first pulse signal Control1 and the second pulse signal Control2 with opposite waveforms in a set cycle;

[0018] The sources s1 and s2 of the triodes Q1 and Q3 are connected and connected to the working current I N ;

[0019] The gates g1 and g2 of the triodes Q1 and Q2 are connected and connected to the first pulse signal Control1; the gates g3 and g4 of the triodes Q3 and Q4 are connected and connected to the second pulse signal Control2;

[0020] The drain d1 of the triode Q1 is connected to the drain d2 of Q2 and connected to the first electrode PoleA; the drain d3 of the triode Q3 is connected to the drain d4 of Q4 and connected to the second electrode PoleB;

[0021] The source s2 of the triode Q2 is connected to the source s4 of Q4 and connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com