Mining anchor pole dynamometer

A bolt dynamometer and bolt technology, applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of cross-sectional area reduction and cross-sectional area increase, achieve reasonable design layout, and solve real-time monitoring and transmission data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

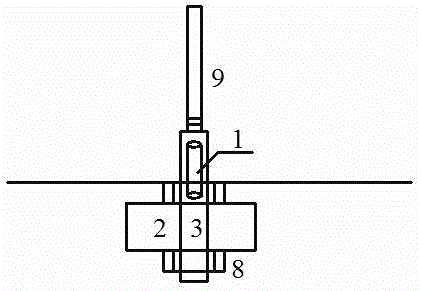

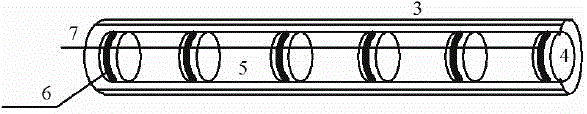

Embodiment 1

[0016] The 3102 working face of the 3# coal seam of a mine is transported along the channel, with a net width of 4.6m, a net height of 4.7m, a maximum height of 5.2m, an average mountain cover thickness of 232m, and a coal pillar width of 15m. One set of the present invention is installed at the 170m opening of the transport channel There are 2 roof bolt dynamometers for mining, 1 for each side, 4 in total. The present invention is a mine bolt dynamometer, which is composed of a resistance strain type bolt force sensor 1 and a secondary monitoring instrument 2. The resistance strain type bolt force sensor 1 includes a hollow sleeve rod 3 and an annular stress sensor group 4 , single ring stress sensor 5, foil resistor 6, foil resistor wire 7 and nut 8 and other parts, the material of the hollow sleeve rod 3 is 25MnSi, the diameter is 20mm, and the length is 40mm. One end of the hollow sleeve rod 3 taps the external thread and the other end taps Internal thread, the end of the ...

Embodiment 2

[0019] The 15109 working face of the 15# coal seam in a mine is transported along the trough, with a clear width of 5.0m and a clear height of 5.0m. The spacing between anchor rods is 1500×1500mm, without anchor cables. A group of mine bolt dynamometers of the present invention are installed at the tunneling head, the hollow sleeve rod 3 has a diameter of 22mm and a length of 45mm, the secondary monitoring instrument 2 has wireless communication, ZigBee communication protocol, and the underground monitoring effect is good. The mine bolt dynamometer The monitoring value has a linear relationship with the working load at the end of the bolt, and the data of the working load at the end of the bolt can be monitored and transmitted in real time. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com