Aging life evaluation method for carbon-fiber composite core wire

A technology for life evaluation and composite core, which is applied in the direction of testing the strength of materials by applying stable tension/pressure, and can solve problems such as composite core creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

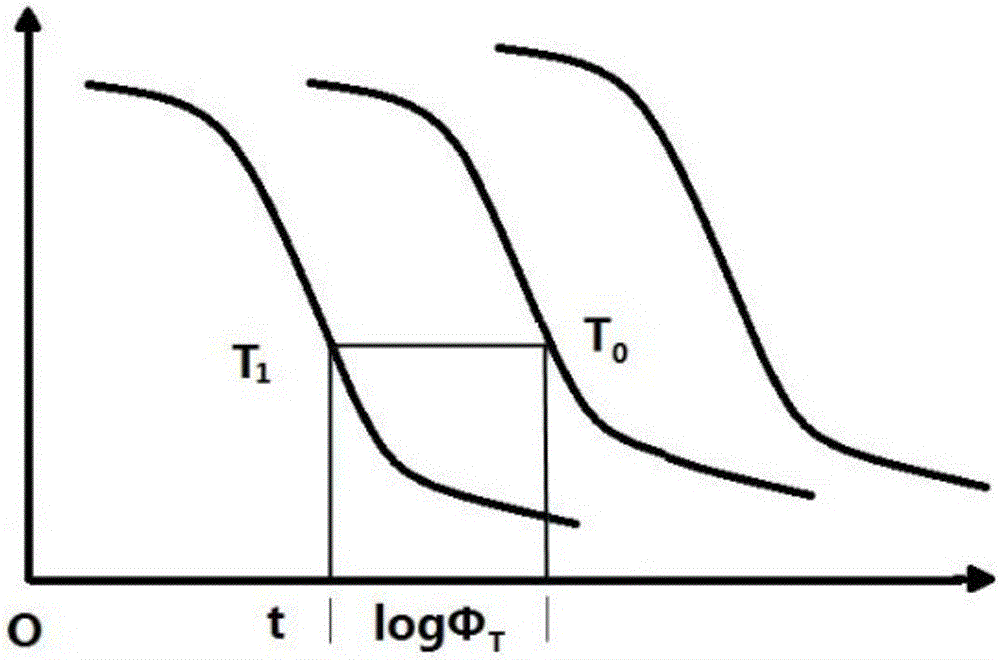

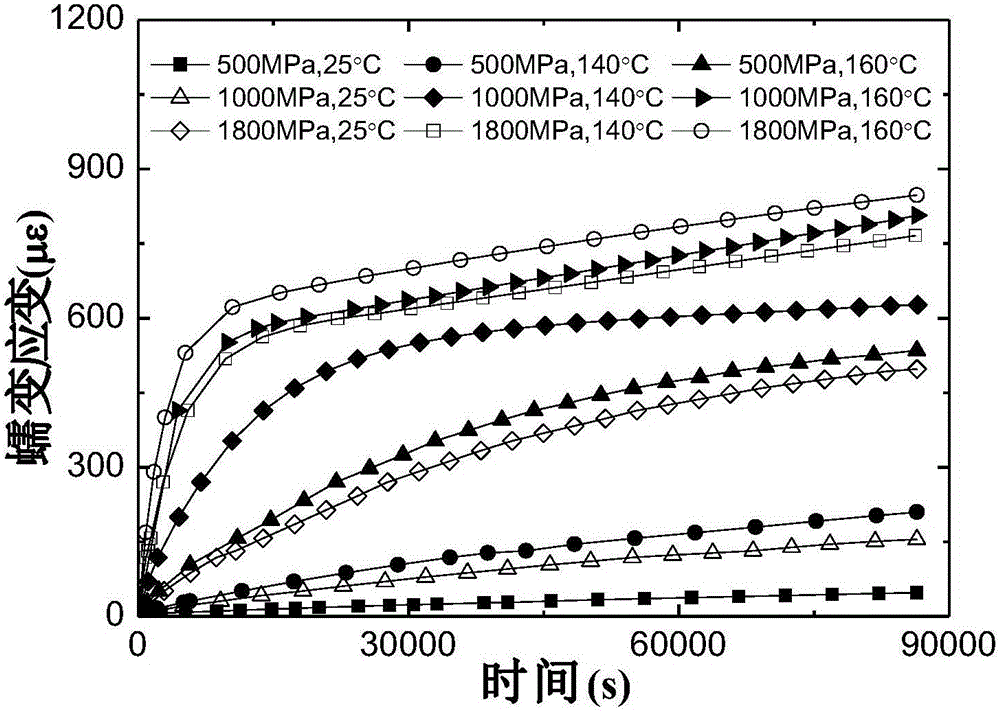

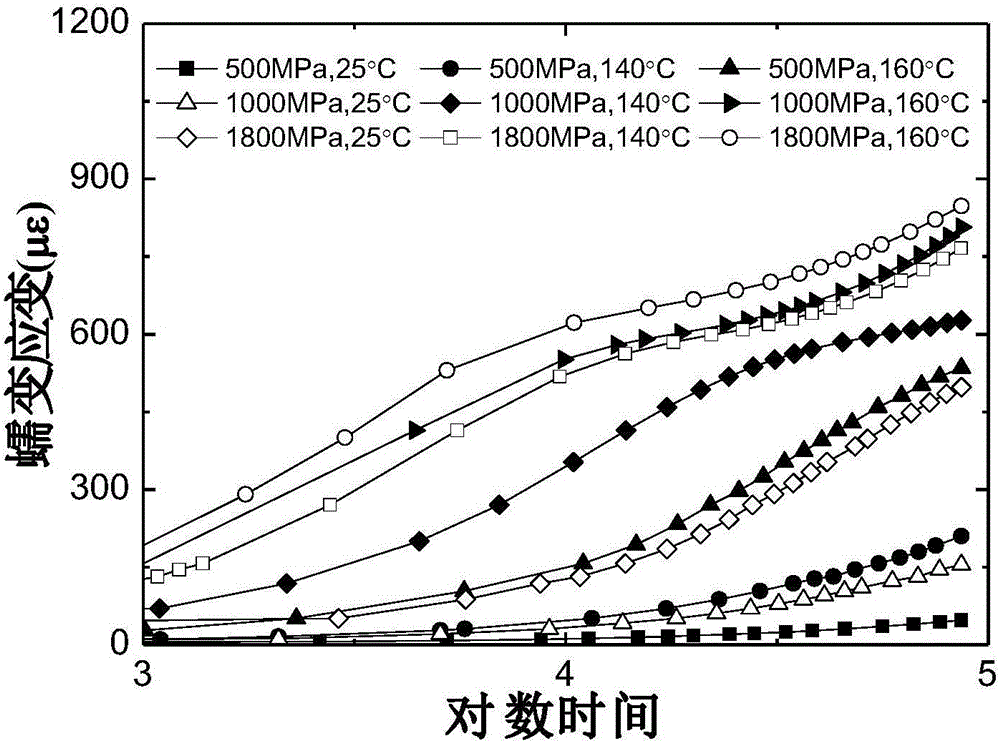

[0041] By measuring the creep behavior of carbon fiber composite core materials under different temperatures and stresses, the material creep under normal working conditions is predicted. The accelerated creep test of the composite mandrel was carried out using a fatigue testing machine. According to the material properties and test conditions, the creep test temperature was set to T 0 =25°C, T 1 =140°C and T 2 =160°C; Since the strength of the carbon fiber composite core is 2000MPa, the creep stress level is taken as 25%, 50% and 90% of the strength value respectively, that is, the stress is taken as σ 2 =1800MPa, σ 1 =1000MPa and σ 0 = 500 MPa. where T 0 temperature and σ 0 For normal use conditions. Based on the equivalent principle, the corresponding time-temperature shift factor, time-stress shift factor and combined temperature-stress shift factor are obtained, and the creep curve under the working conditions of engineering concern is obtained, and the long-term c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com