Fiber heat conductivity determination method

A technology of thermal conductivity and fiber, which is applied in the field of thermal conductivity measurement of materials, can solve problems such as measurement limitations of inhomogeneous or anisotropic materials, and achieve the effect of simple and practical preparation method, convenient operation and simple testing principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In this embodiment, the fiber to be tested is carbon fiber (T700SC-12000-50C), and the thermal conductivity meter is a solid hot wire method thermal conductivity meter developed by Xi'an Xiaxi Electronic Technology Co., Ltd.

[0056] The method for measuring fiber thermal conductivity in the present embodiment comprises the steps:

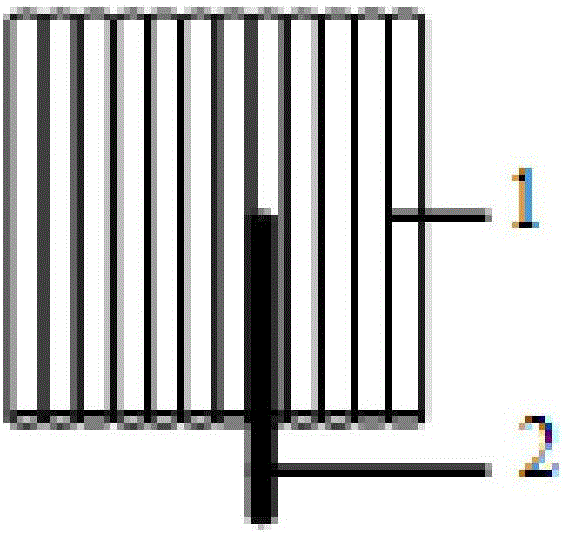

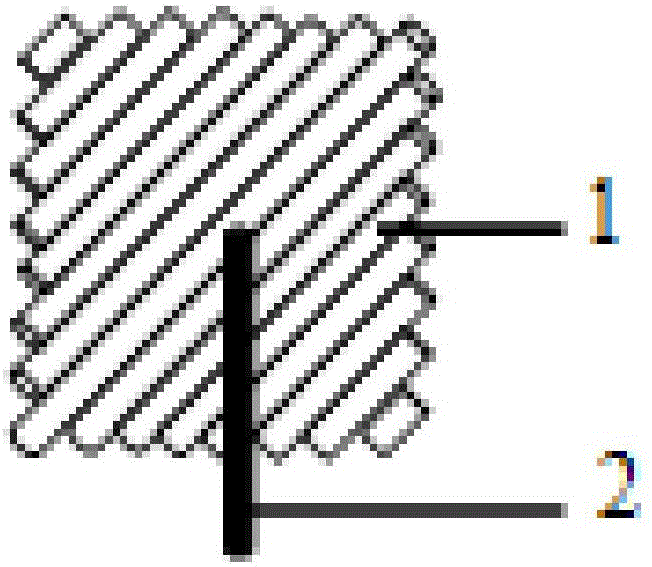

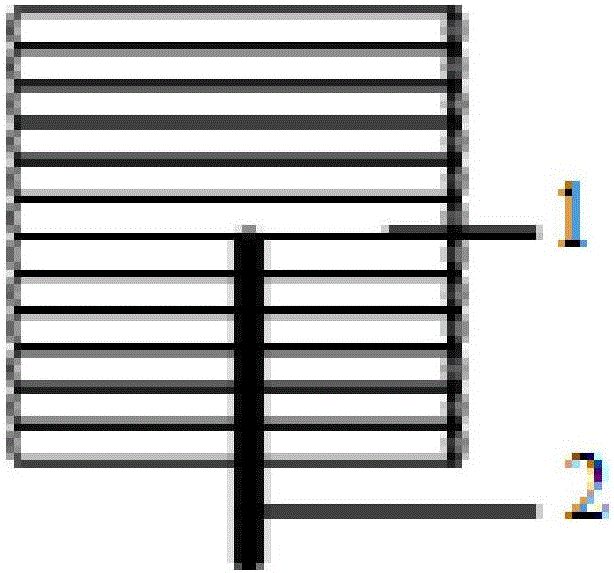

[0057] (1) Preparation of test samples: A carbon fiber bundle is evenly wound in parallel to form test samples with 7 arrangement angles. Each test sample is composed of 4 parallel samples 1, and the size of parallel sample 1 is 40mm×40mm×0.93 mm.

[0058] In order to reduce the preparation time of parallel sample 1, 7 arrangement angles are set, which are 0°, 15°, 30°, 45°, 60°, 75° and 90°, among which 0° and 90°, 15° and 75°, 30° and 60° are complementary, that is, by rotating the center of the parallel sample 1 at one arrangement angle by 90°, it can be transformed into a parallel sample 1 at another arrangement angle that is complement...

Embodiment 2

[0067] The method for measuring fiber thermal conductivity in the present embodiment specifically comprises the following steps:

[0068] (1) Sample preparation: the fibers to be tested are uniformly wound in parallel into 5 test samples with different arrangement angles by winding method, and the test samples for each arrangement angle are composed of 3 parallel samples 1;

[0069] (2) Determination of thermal conductivity of test sample:

[0070] (2-1) Place the test sample prepared in step (1) in a constant temperature and humidity environment for 10 hours;

[0071] (2-2) Place the stabilized test sample in step (2-1) on the thermal conductivity meter, and place the hot wire sensor 2 in the middle of the two parallel samples 1 to form a sandwich structure, and then measure the thermal conductivity;

[0072] (3) Data processing:

[0073] (3-1) Select a point as a dot, and use the dot as a starting point to draw 5 rays that are equally divided along the circumference. Each ...

Embodiment 3

[0086] The method for measuring fiber thermal conductivity in the present embodiment specifically comprises the following steps:

[0087] (1) Sample preparation: the fibers to be tested are uniformly wound in parallel into 6 test samples with different arrangement angles by winding method, and the test samples for each arrangement angle are composed of 2 parallel samples 1;

[0088] (2) Determination of thermal conductivity of test sample:

[0089] (2-1) Place the test sample prepared in step (1) in a constant temperature and humidity environment for 30 hours;

[0090] (2-2) Place the stabilized test sample in step (2-1) on the thermal conductivity meter, and place the hot wire sensor 2 in the middle of the two parallel samples 1 to form a sandwich structure, and then measure the thermal conductivity;

[0091] (3) Data processing:

[0092] (3-1) Select a point as a circle point, and draw 6 rays equally divided along the circumference with the circle point as the starting poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com