A capacitance measurement method based on the principle of electrostatic self-excited vibration

A technology of self-excited vibration and capacitance measurement, which is applied in the direction of capacitance measurement, measuring device, and electric variable measurement, can solve the problems of complicated circuit debugging and low measurement resolution, and achieve high resolution, simple test principle and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

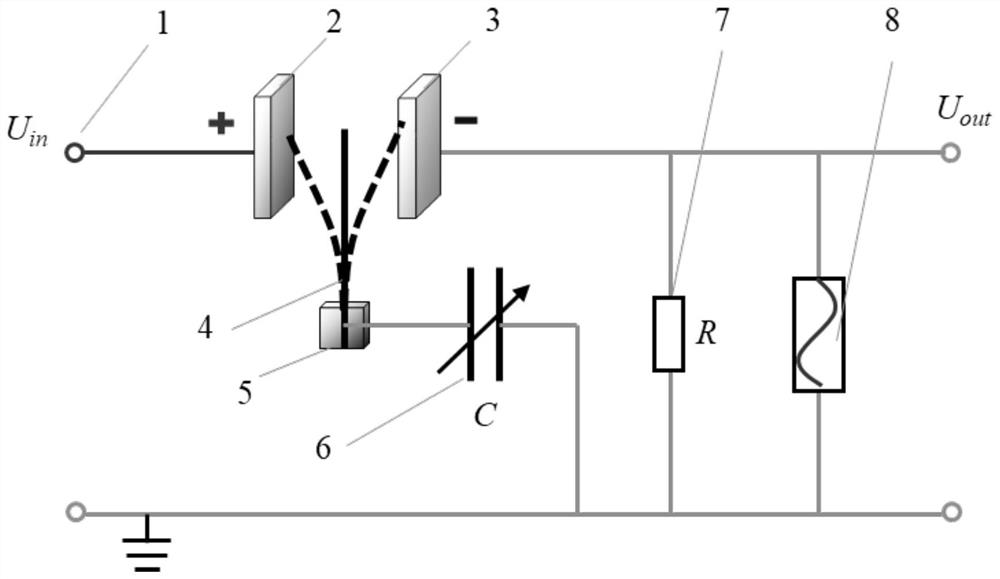

[0028] Embodiment one: if figure 1 As shown, the capacitance measurement method based on the electrostatic self-excited vibration principle provided by the present invention includes a high-voltage DC power supply 1, a positive electrode plate 2, a negative electrode plate 3, a conductive microbeam 4, an insulating support 5, a capacitor to be measured 6, and a sampling resistor 7. Signal collector 8. Wherein, the positive pole of the high-voltage DC power supply 1 is connected to the positive electrode plate 2, and the negative pole is grounded. The conductive microbeam 4 is fixed on the insulating support 5 and placed between the positive electrode plate 2 and the negative electrode plate 3 . One end of the capacitor 6 to be tested is connected to the conductive micro-beam 4 , and the other end is connected to the negative pole of the high-voltage DC power supply 1 (grounded). One end of the sampling resistor 7 is connected to the negative electrode plate 3, and the other ...

Embodiment 2

[0030] Embodiment two: figure 1 The support method of the medium-conducting microbeam 4 adopts the form of simple support at both ends, and other technical features are the same as in the first embodiment.

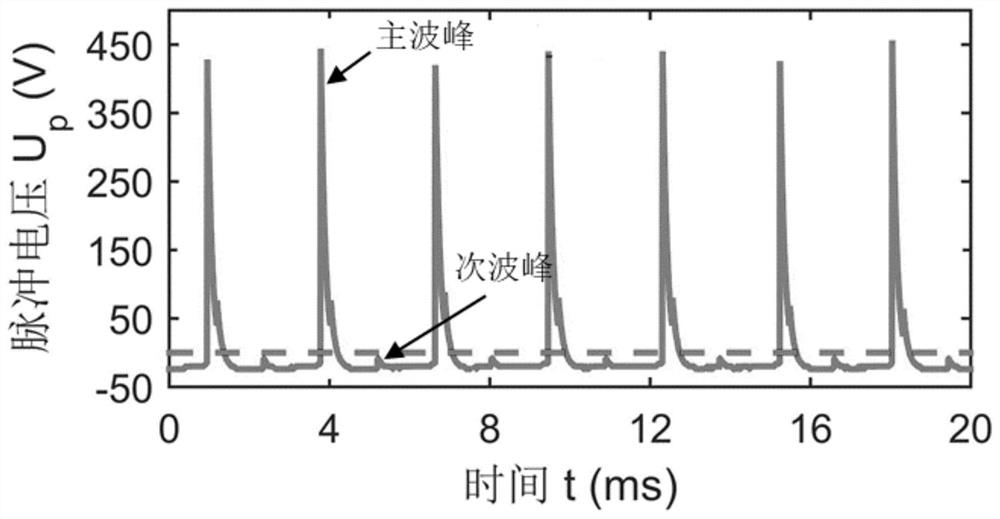

[0031] The pulse voltage signal measured by the capacitance measurement method proposed by the present invention is as follows: figure 2 As shown, when the conductive microbeam 4 collides with the negative electrode plate 3, a main peak of the pulse voltage is generated at both ends of the sampling resistor 7; when the conductive microbeam 4 collides with the positive electrode plate 2, a secondary peak of the pulse voltage is generated at both ends of the sampling resistor 7. Wherein, the size of the capacitor 6 to be tested has a linear relationship with the main peak of the pulse voltage. In this example, the average amplitude of the main peak of the pulse voltage is 484.0V, and the calculated capacitance to be tested is 7.47pF.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com