Snow depth measurement system based on covering detection

A technology for measuring systems and coverings, applied to measuring devices, rainfall/precipitation gauges, instruments, etc., can solve problems such as measurement errors, large influence of temperature and wind speed, and difficult accurate measurement of snow rulers, so as to reduce the number of false alarms and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

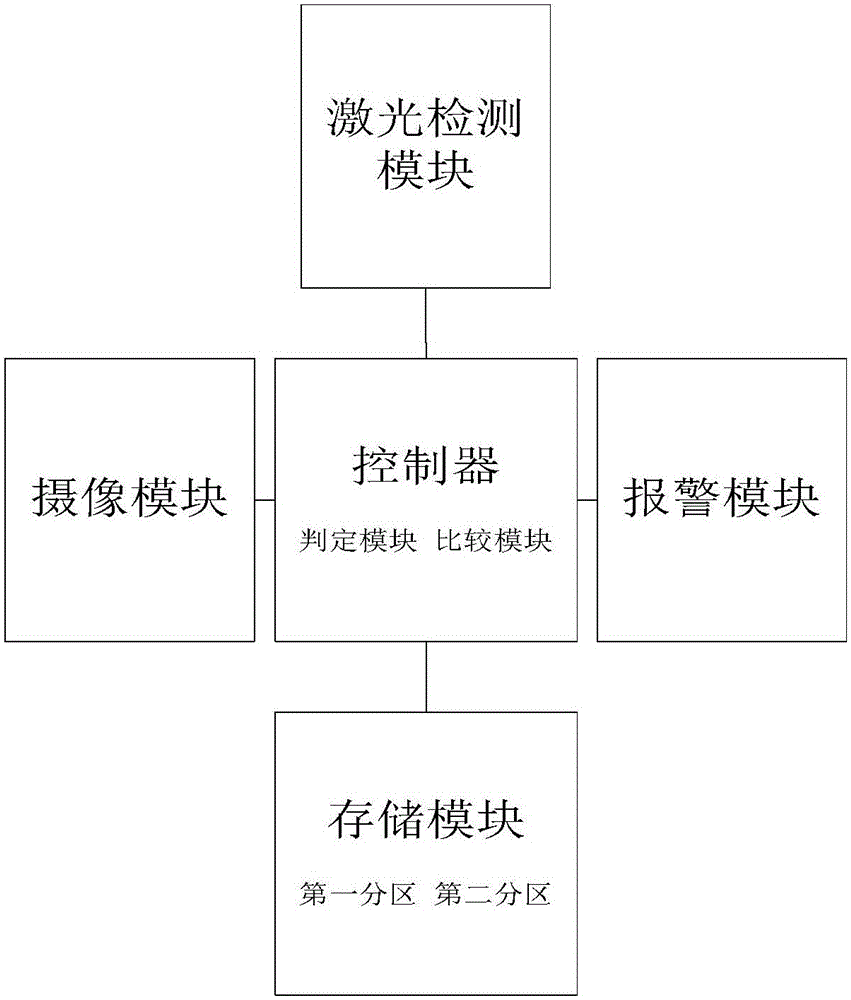

[0015] Such as figure 1 As shown, the snow depth measurement system of the present invention includes a laser detection module, a storage module, a camera module, a controller, and an alarm module.

[0016] The laser detection module is used to detect the snow depth value of the area to be measured in real time;

[0017] a storage module, configured to store the snow depth value measured by the laser detection module, which includes a first partition and a second partition;

[0018] The camera module is used to capture the image of the detection area;

[0019] A controller, which includes a determination module and a comparison module, and the controller is electrically connected to the laser detection module, the storage module, the camera module, and the alarm module respectively;

[0020] The controller starts the laser detection module to measure the snow depth of the area to be measured at the first moment, and controls the laser detection module to send the detection v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com