Transformation method for TVS-2M fuel rod film-coating equipment

A TVS-2M, rod coating technology, applied in the direction of manufacturing reactors, reactors, reducing greenhouse gases, etc., can solve the problems of unsuitable production equipment, reduce the risk of equipment use, ensure safety, and ensure the effect of normal production work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be clearly and completely described below in combination with specific embodiments and accompanying drawings.

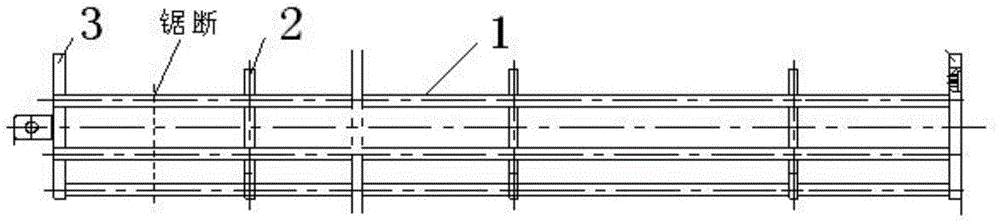

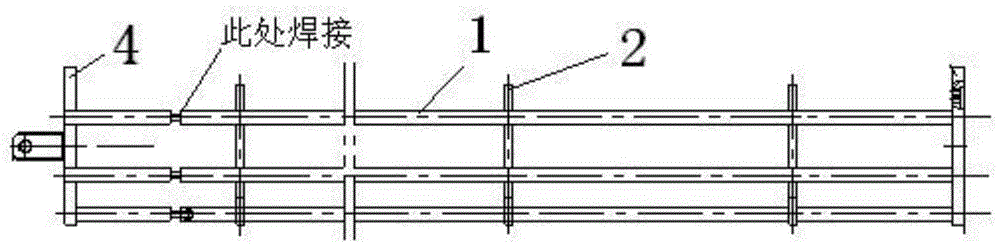

[0023] Such as figure 1 , 2 As shown, a transformation method of TVS-2M fuel rod coating equipment is applied to VVER-1000 production equipment to be suitable for the production of TVS-2M fuel rods, including the transformation of the coating material box and the guide tube Cleaning box modification:

[0024] (1) Transformation of coating material box

[0025] (1.1) Saw off the 5 pull columns at the distance of 100mm from the hanging plate of the original coating material box, and remove the part with the hanging plate;

[0026] (1.2) Use 5 stainless seamless steel tubes with a diameter of 22mm to weld the plugs at both ends of the nozzle, and weld them at the sawing position of the original coating material box; straighten and weld the coating material box after welding Seam surface polishing;

[0027]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com