Battery connector and preparation method thereof, battery connecting assembly, battery bank, battery pack and electric vehicle

A battery connection piece, battery connection technology, applied in electric vehicles, conductive connections, electrical component connections, etc., to overcome energy shocks, save manufacturing costs, and ensure connection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing a battery connecting piece, the method comprising: processing the metal piece to form a first metal piece, a buffer part and a connecting part connected in sequence, and connecting the connecting part to the end of the second metal piece Electromagnetic pulse welding is used for welding.

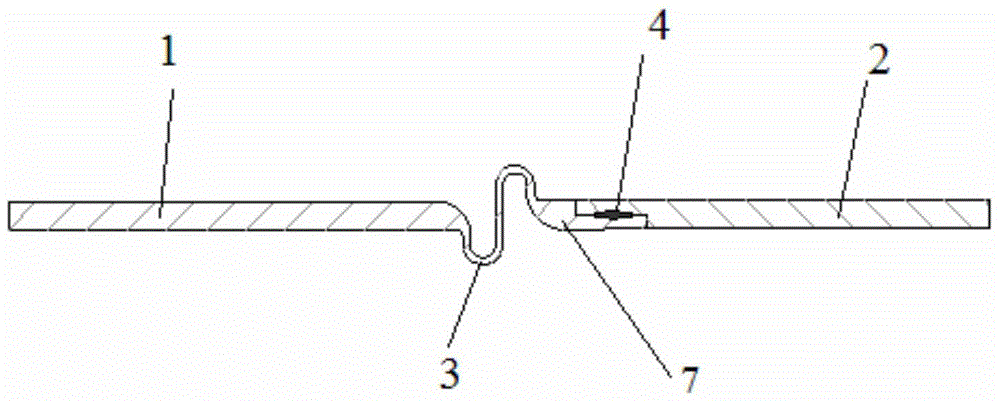

[0048] According to the present invention, wherein, the end of the connecting part forms a concave first step; the end of the second metal sheet is processed to form a concave second step, and the first step and the second step are interlocked and parallel placed at intervals with a gap of 0.5-4 mm; the first step and the second step are welded by electromagnetic pulse welding.

[0049] According to the present invention, wherein, the buffer portion is formed into a sine wave shape by thinning and stretching.

[0050] According to the present invention, the buffer portion 3 is annealed after being thinned and shaped, and the ...

Embodiment 1

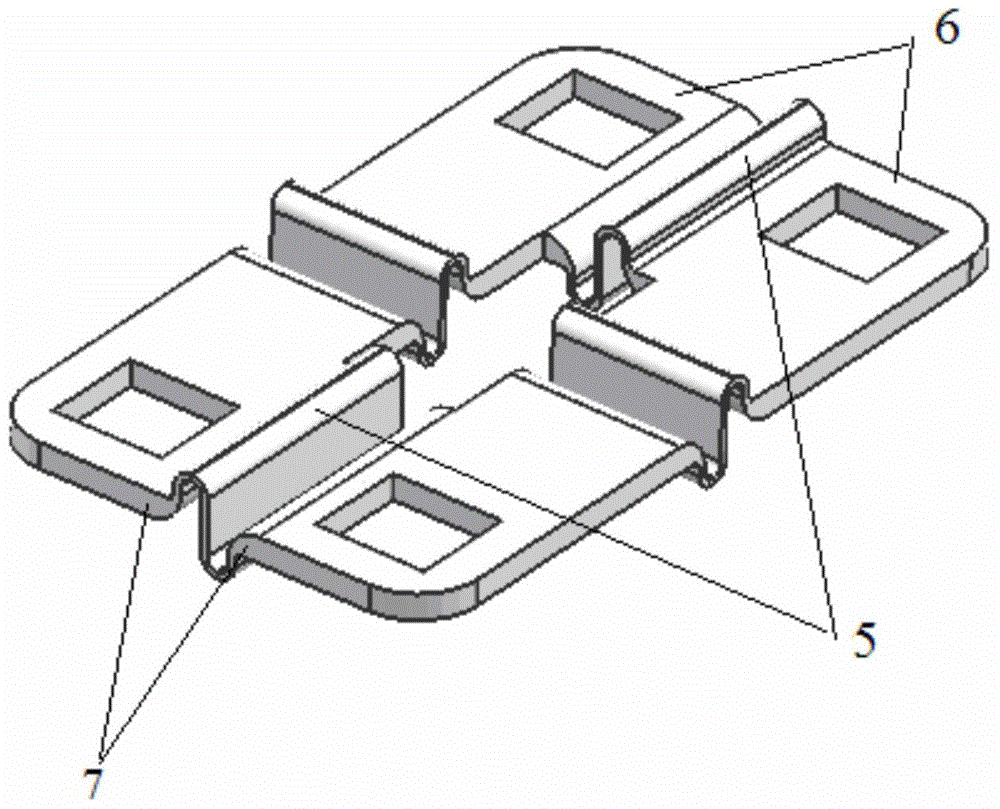

[0067] This embodiment is used to illustrate the battery connection sheet, battery connection assembly and battery pack provided by the present invention.

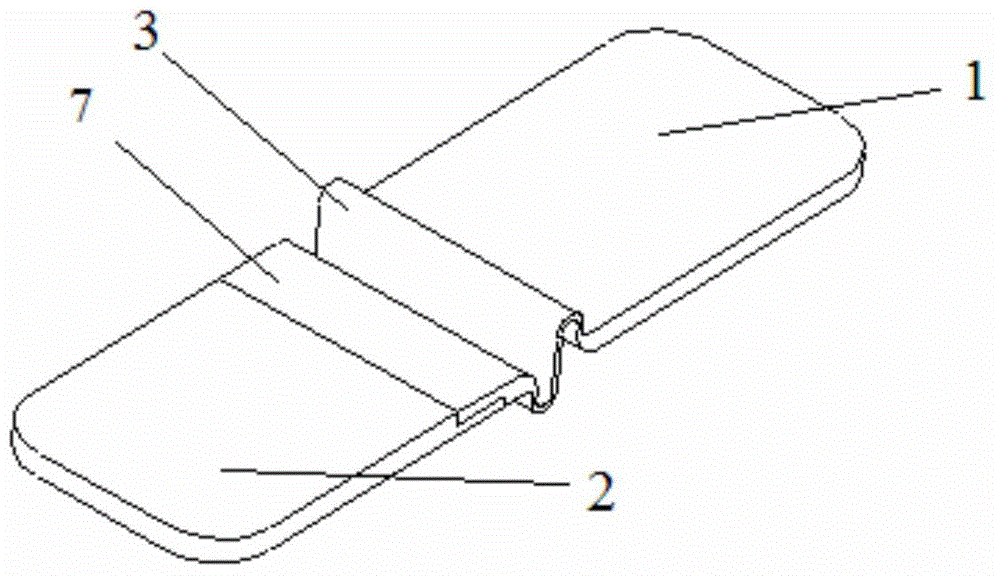

[0068] (1) One end of the whole metal plate is processed to form a connecting portion with a first step, and the other end is processed as a first metal sheet, and the part between the first metal sheet and the connecting portion that is adjacent to the connecting portion is processed into a sine wave shape And annealed, the hardness is Vickers 22 as a buffer. Processing the second metal sheet to form the end of the second step, such as figure 2 shown. Buckle the first step of the connection part and the second step of the second metal sheet and place them in parallel at an interval of 2mm, then perform electromagnetic pulse welding (welding equipment model PS48-16 / 25, PST company), and the welding energy is 32KJ to obtain the connecting piece ,Such as figure 1 shown. Wherein, the width of the welding connection betwe...

Embodiment 2

[0076] This embodiment is used to illustrate the battery connection sheet, battery connection assembly and battery pack provided by the present invention.

[0077] (1) One end of the whole metal plate is processed to form a connecting portion with a first step, and the other end is processed as a first metal sheet, and the part between the first metal sheet and the connecting portion that is adjacent to the connecting portion is processed into a sine wave shape And annealed, the hardness is Vickers 25 as a buffer. Processing the second metal sheet to form the end of the second step, such as figure 2 shown. Fasten the first step of the connection part and the second step of the second metal sheet and place them in parallel at an interval of 1.5mm, then perform electromagnetic pulse welding (welding equipment model PS48-16 / 25, PST company), the welding energy is 60KJ, and the connection is obtained. slices, such as figure 1 shown. Wherein, the width of the welding connectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com