Transmission mechanism of oral irrigator

A technology of transmission mechanism and punching device, which is applied to transmission parts, electromechanical devices, mechanical equipment, etc., can solve the problems of shortening the service life of the meshing gear punching device, unable to adjust the meshing gear gap, and meshing gear meshing gear wear and other problems. Achieve the effect of eliminating assembly tolerances, extending service life, and uniform gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

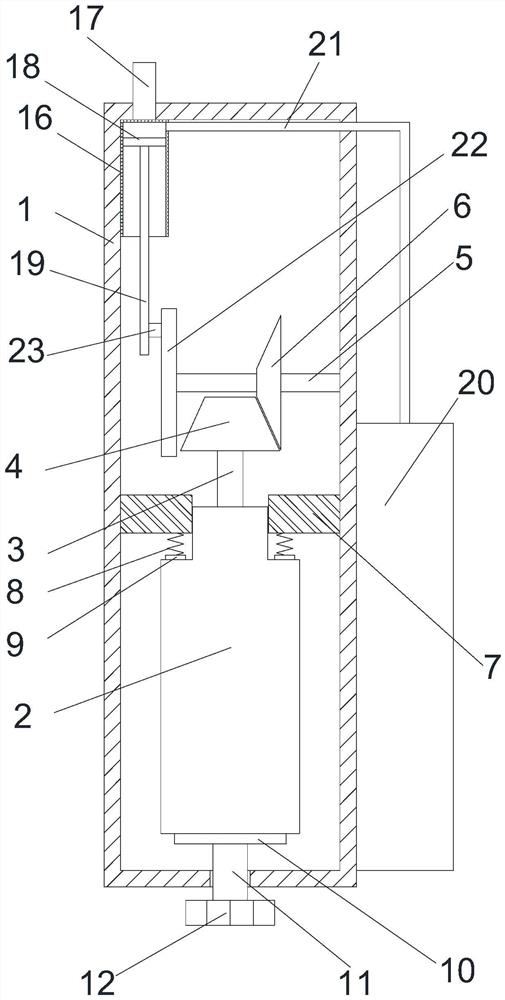

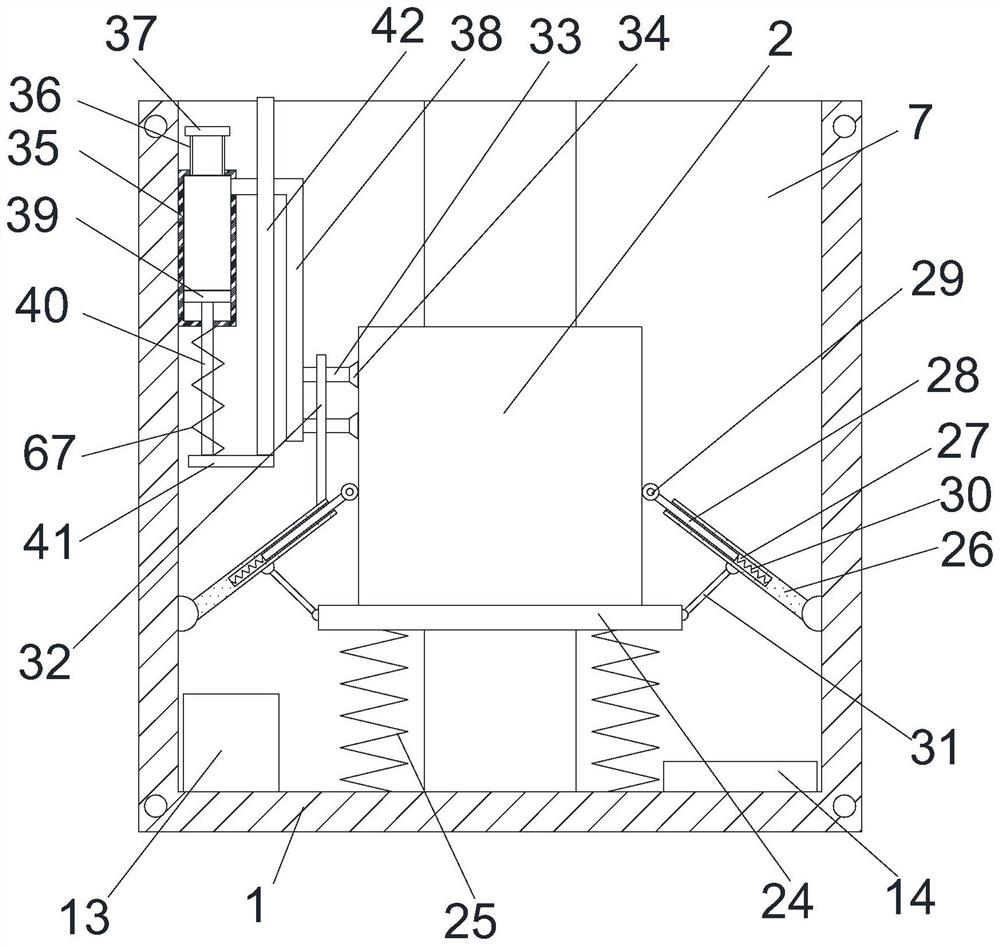

[0051] The embodiment of the present invention provides a dental flosser transmission mechanism, such as Figure 1-5 As shown, it includes: a housing 1, a motor 2 is arranged in the housing 1, a first rotating shaft 3 is arranged at the output end of the motor 2, a first bevel gear 4 is arranged on the first rotating shaft 3, and a first bevel gear 4 is arranged on the first bevel gear. A second rotating shaft 5 is arranged above the gear 4, and one end of the second rotating shaft 5 is rotationally connected with the inner wall of the housing 1, and a second bevel gear 6 is arranged on the second rotating shaft 5, and the second bevel gear 6 is connected to the inner wall of the housing 1. The first bevel gear 4 is meshed, and an adjustment assembly is also arranged in the housing 1 , and the adjustment assembly is used to adjust the position of the motor 2 .

[0052] The working principle and beneficial effects of the above technical solution are as follows: in the present i...

Embodiment 2

[0054] On the basis of above-mentioned embodiment 1, as figure 1 As shown, the adjustment assembly includes:

[0055] Two guide plates 7, the two guide plates 7 are symmetrically arranged on the left and right sides of the output end of the motor 2, one side of the guide plate 7 is fixedly connected to the inner wall of the housing 1, and the other side of the guide plate 7 The side is slidingly connected with the outer wall of the output end of the motor 2;

[0056] The first spring 8, the first spring 8 is arranged between the guide plate 7 and the motor 2, one end of the first spring 8 is fixedly connected with the bottom wall of the guide plate 7, the first spring 8 The other end extends above the motor 2 and is provided with a pressing plate 9, the bottom wall of the pressing plate 9 abuts against the outer wall of the upper end of the motor 2;

[0057] A support plate 10, the support plate 10 is arranged on the lower surface of the motor 2, and the upper surface of the...

Embodiment 3

[0062] On the basis of embodiment 1 or 2, such as figure 2 As shown, the housing 1 is also provided with a power supply 13 and a first controller 14, the power supply 13 is electrically connected to the motor 2, and the first controller 14 is connected to the power supply 13 and the motor 2 respectively. 2 electrical connection.

[0063] The working principle and beneficial effects of the above technical solution are: the housing 1 is provided with a power source 13 and a first controller 14, the power source 13 can supply power to the motor 2 and the first controller 14, and the first controller 14 can control the motor 2 to work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com