Coupling system

A technology for receiving parts and protrusions, applied in the direction of connecting components, thin plate connections, electrical equipment casings/cabinets/drawers, etc., can solve problems such as increased assembly time, component misalignment, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

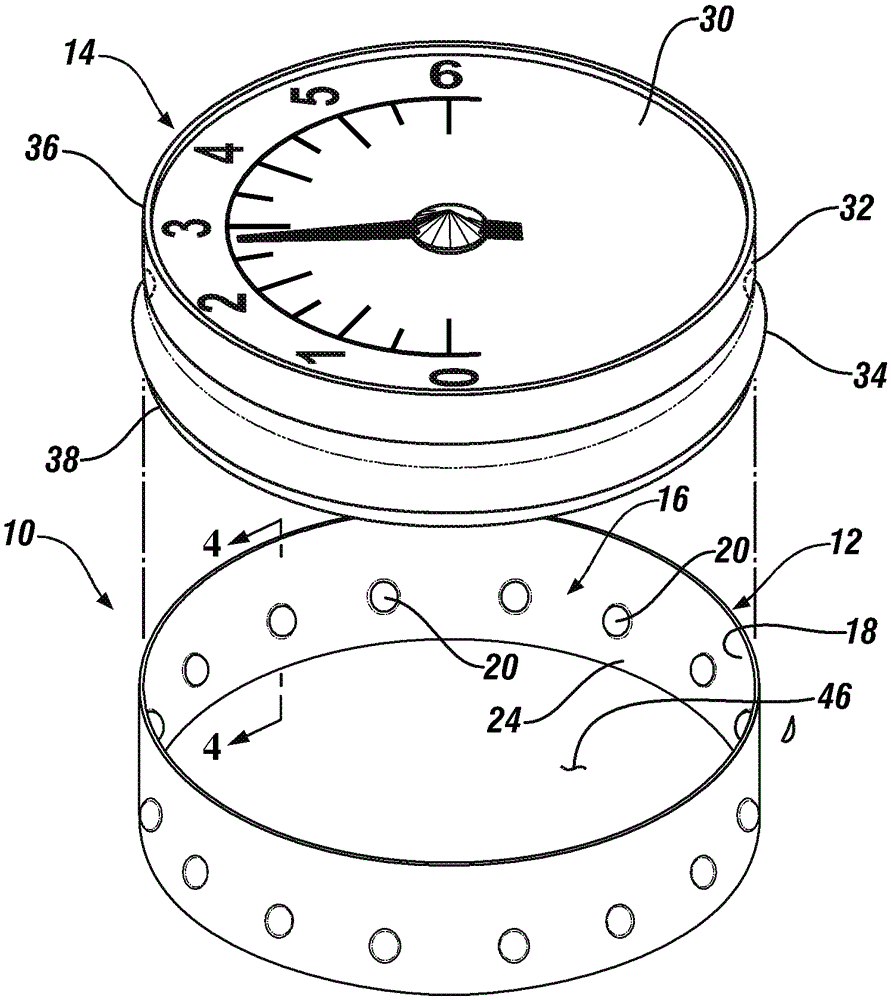

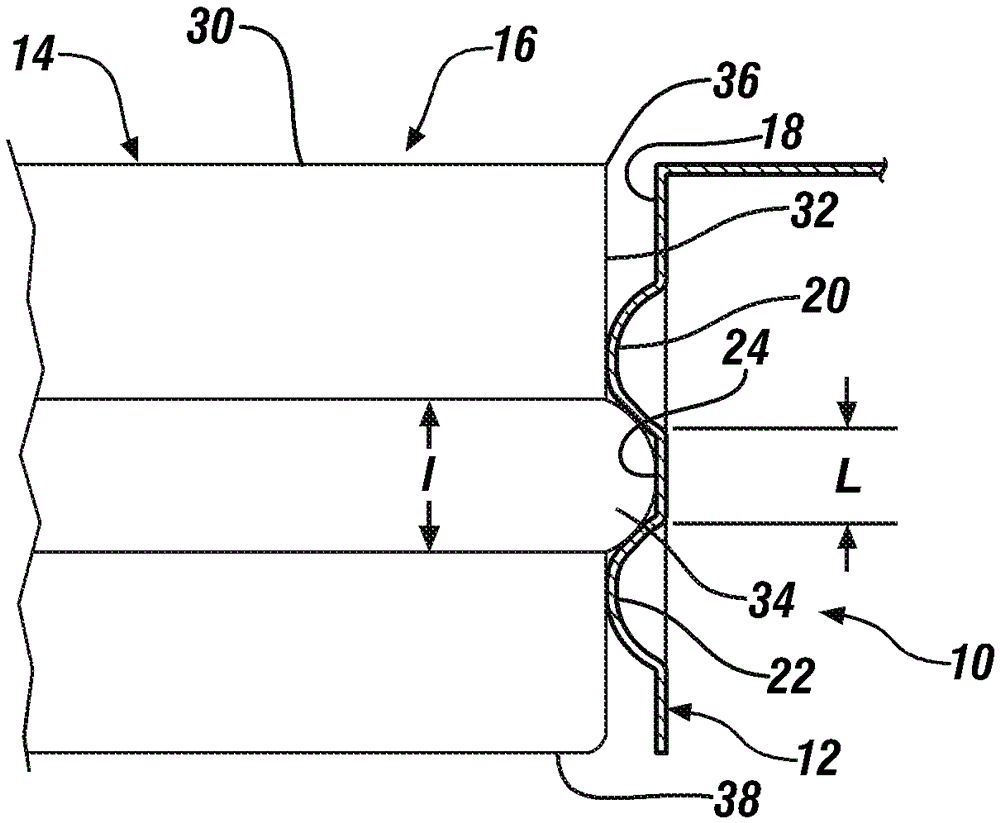

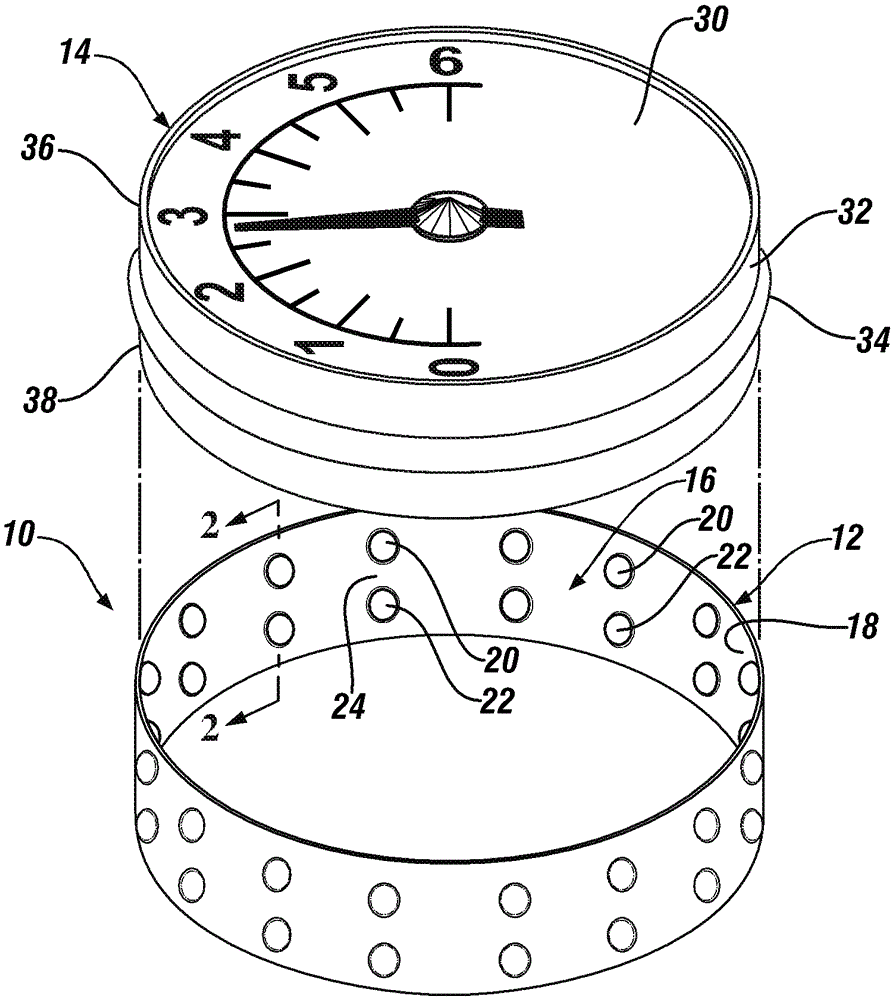

[0038] The following description is merely exemplary in nature and is not intended to limit the disclosure, its application, or uses. For example, the illustrated embodiments may be applied to vehicle components, but the systems disclosed herein may be used with any suitable component to provide fastening and retention of mating components and component applications, including many industrial, consumer products such as , consumer electronics, various appliances, etc.), transportation, energy, and aerospace applications, and specifically includes many other types of automotive components and applications, such as various interior, exterior, electrical, and under-hood automotive components and applications. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

[0039] Any suitable material may be used for the counterpart components and features thereof disclosed herein and discussed further bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com