Calibrate a CMM with a calibration laser head at the tool center point

A coordinate measuring machine and laser head technology, applied in the field of calibration data, can solve expensive and time-consuming problems, achieve low maintenance costs, improve accuracy and efficiency, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

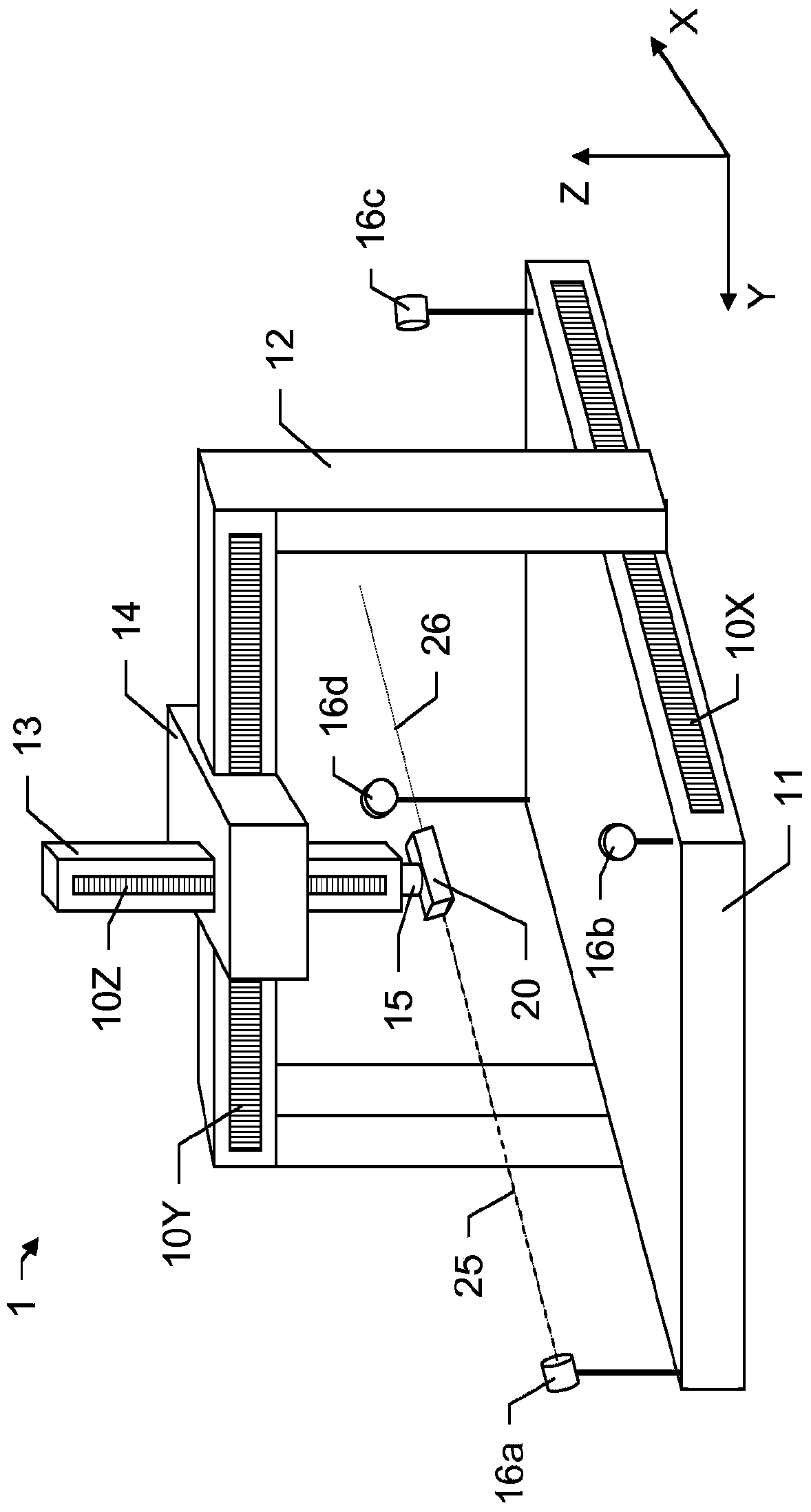

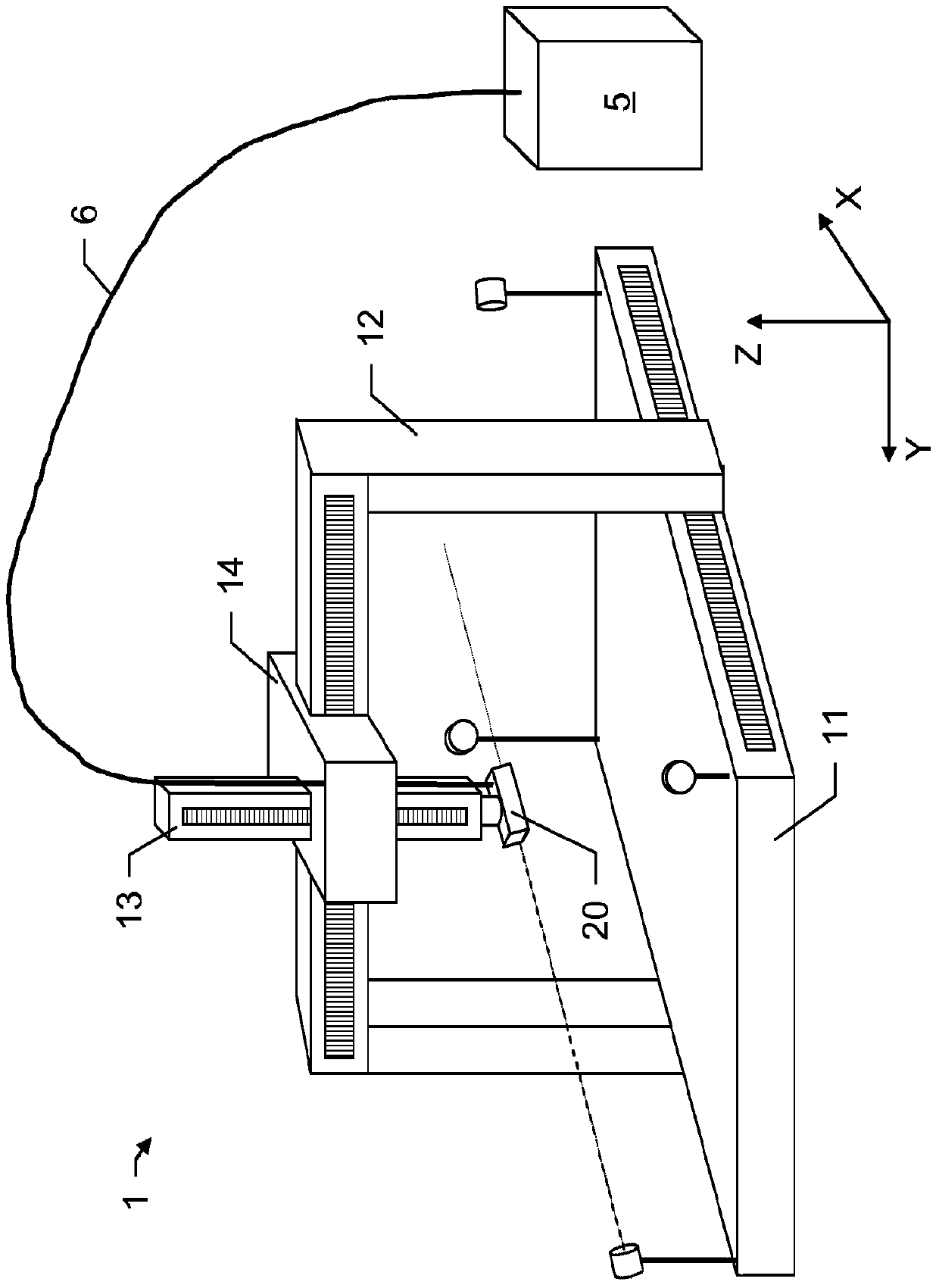

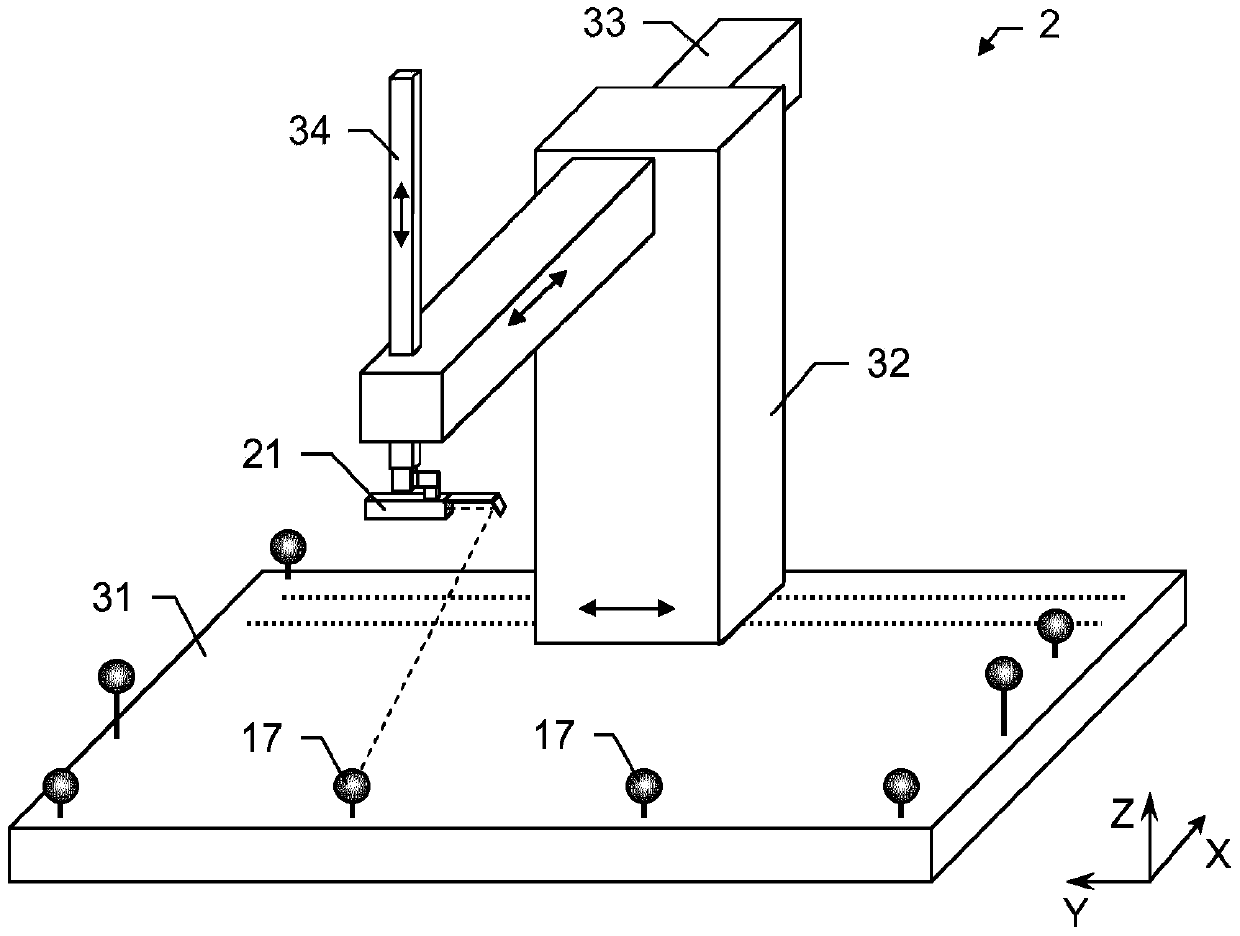

[0085] exist figure 1 In , an exemplary embodiment of a gantry coordinate measuring machine 1 (CMM) according to the invention is depicted, the coordinate measuring machine 1 comprising a base 11 and comprising means for coupling a tool carrier 15 (probe 15) to the base 11 A frame structure comprising several frame parts 12, 13, 14 movable relative to one another. The first frame part 12 is a mast with two mast legs connected at their upper ends by a bridge. Driven by a drive mechanism (not shown), the frame member 12 is movable along the longitudinal sides of the base 11 . This direction corresponds to the first direction X. The movement of the frame part 12 is in particular carried out by a toothed rack attached to the base 11 , which meshes with a pinion on the frame part 12 , but can alternatively be realized according to solutions known from the prior art.

[0086] The carriage 14 is arranged movably on the bridge of the frame part 12 . The movement of the carriage 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com