Method for land leveling seedbed land by utilizing track device

An equipment pair and track technology, applied in the fields of land preparation methods, applications, land preparation machinery, etc., can solve the problems of low efficiency, use requirements, pre-leveled seedbed plane calibration, and the overall levelness cannot be guaranteed. Overall level consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

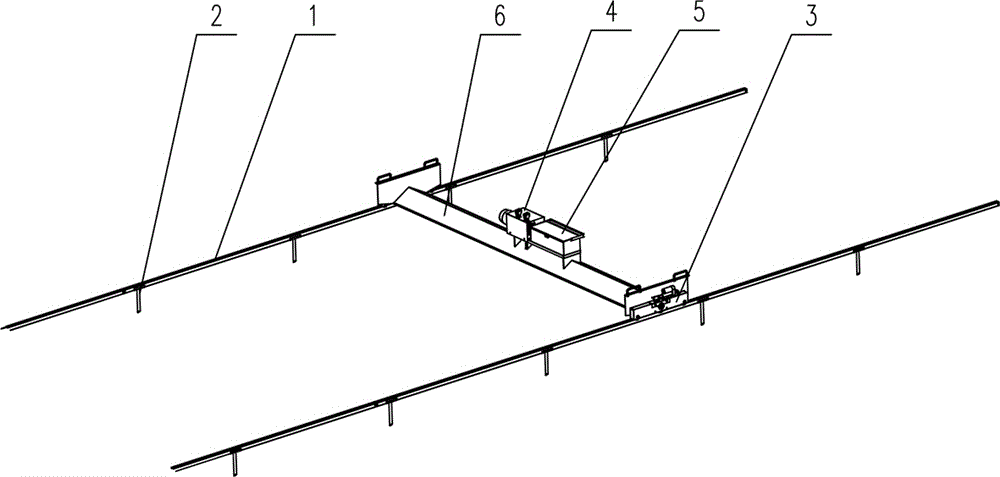

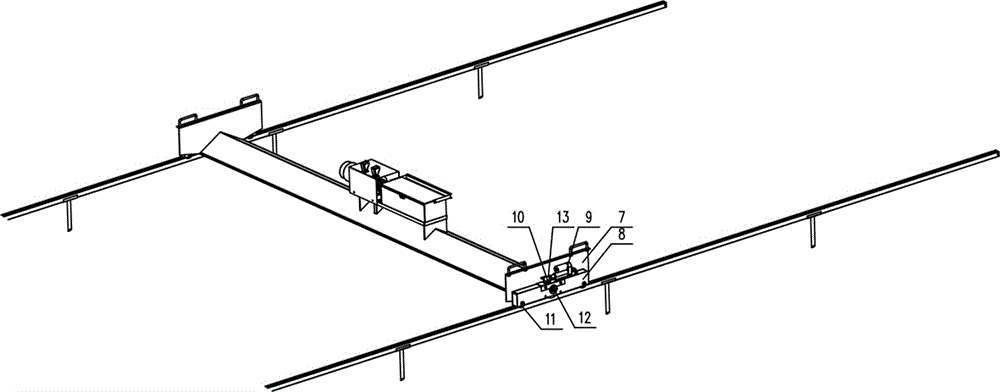

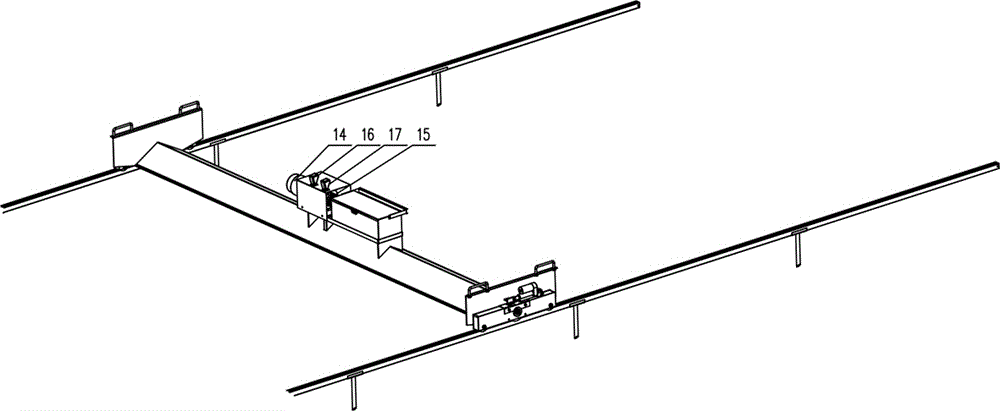

[0018] The perforated track 1 is made of square hollow ordinary iron material, the size is 30mm*30mm, the size of the square hole is 4mm*7mm, and the hole distance is 7mm; the height of the track U-shaped bracket 2 is 220mm, the voltage of the battery 5 is 48 volts, and the triangle is double-sided The size of the blade level shovel 6 is 3007*310*131mm, the size of the fixed connecting plate 7 is 600*200*3mm, the size of the mounting seat 8 is 520*80*46mm, the voltage of the electric push-pull device 9 is 48V and the stroke is 30mm, the gear 10 is a U-shaped limiting gear, the U-shaped plate diameter is φ110mm, the gear tooth bottom diameter is φ90mm, the gear tooth tip diameter is φ100mm, the moving wheel 11 is a U-shaped limited wheel, the U-shaped plate diameter is φ58mm, and the diameter of the wheel diameter is φ38mm, the size of the gear shaft 12 is φ16*3119mm, and the fixed point is lug-shaped, which is composed of a connecting plate and a support plate. The specificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com