A filter type double heating distillation atomization device

A dual heating and atomization device technology, which is applied in the field of electronic cigarettes, can solve the problems of sour taste, poor air tightness, and high smoke temperature, so as to reduce oral irritation, reduce acid gas and harmful substances, and solve temperature problems. overheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

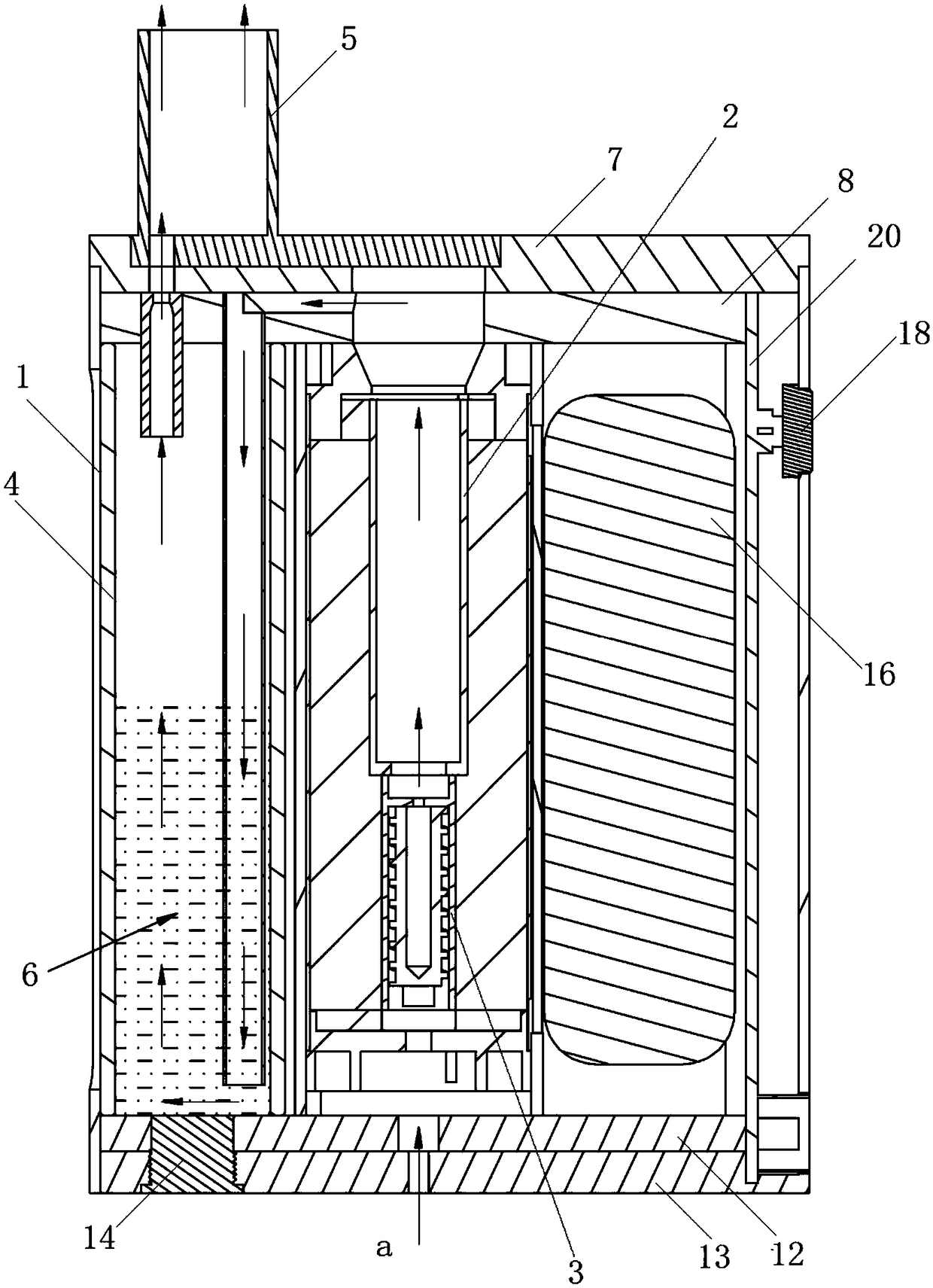

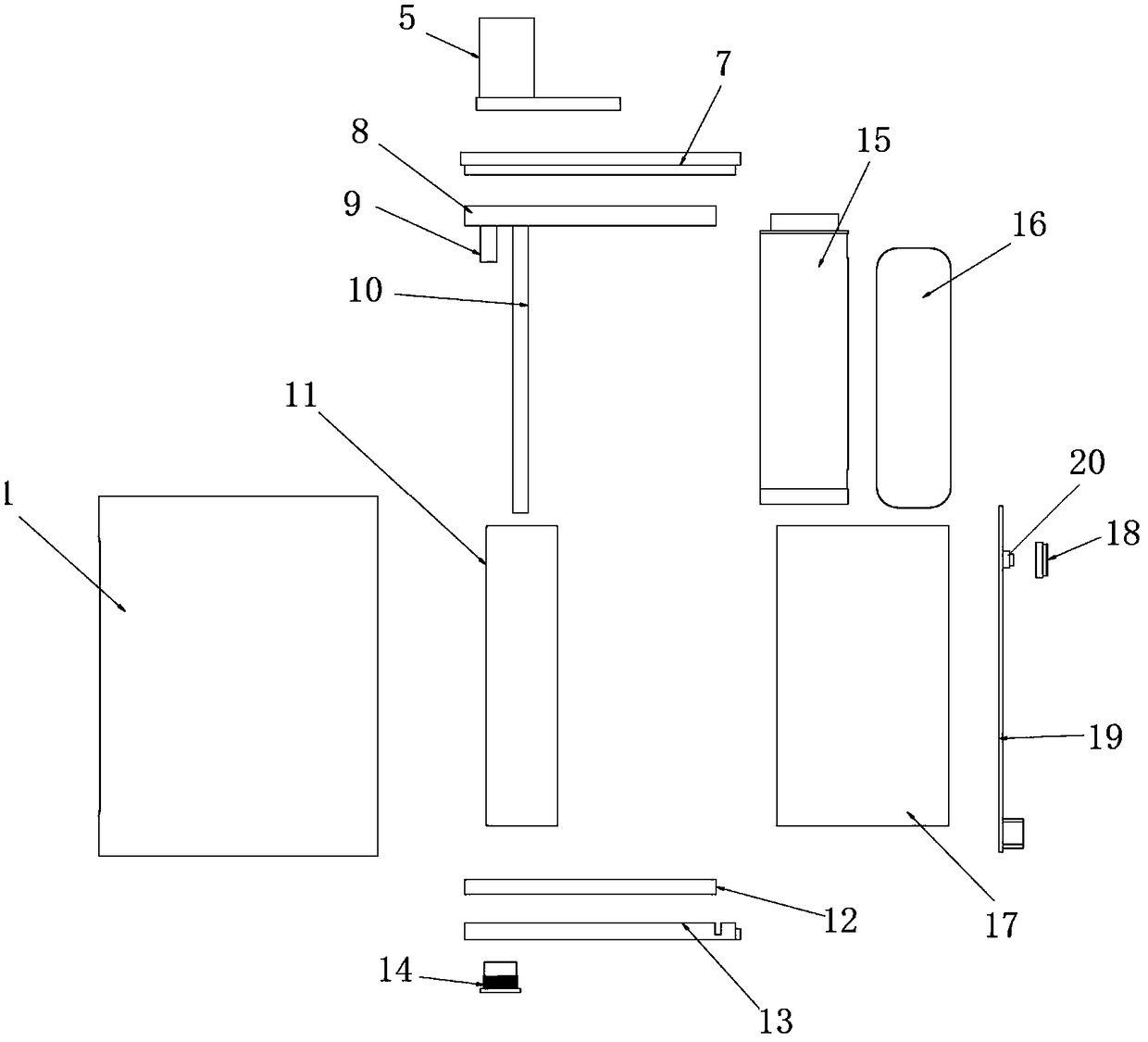

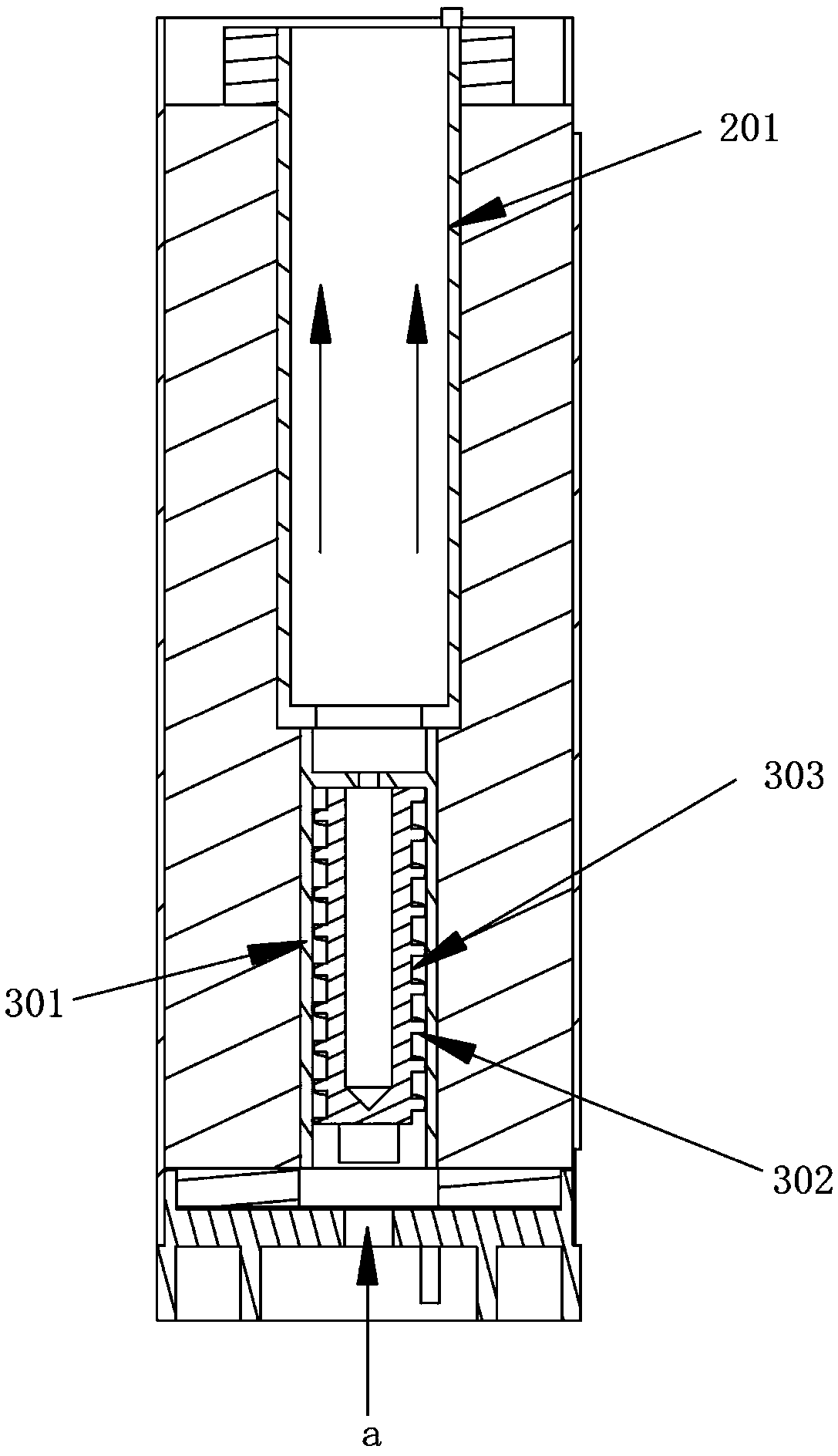

[0025] refer to Figure 1 to Figure 5 , in one embodiment, a filter-type dual heating distillation atomization device, comprising a casing 1, a heating assembly arranged in the casing 1, a filter assembly 4, and a mouthpiece 5 arranged on the casing 1, The heating assembly includes a first heating system 3 and a second heating system 2 airtightly connected to the first heating system 3, the second heating system 2 is airtightly connected to the filter assembly 4, and the filter assembly 4 is airtightly connected to the cigarette holder 5 assembly, wherein the external air a flows into the first heating system 3 from the air inlet on the casing 1, and enters the second heating system 3 after being preheated Heating system 2, cigarettes (not shown) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com