Shoe-washing machine

A technology of shoe washing machine and shoe rack, which is applied in the field of shoe washing machines, can solve the problems that the inside of shoes cannot be thoroughly cleaned, it is difficult to completely remove stains, and the water flow requires a lot, so as to achieve good washing effect, simple structure, and improved washing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

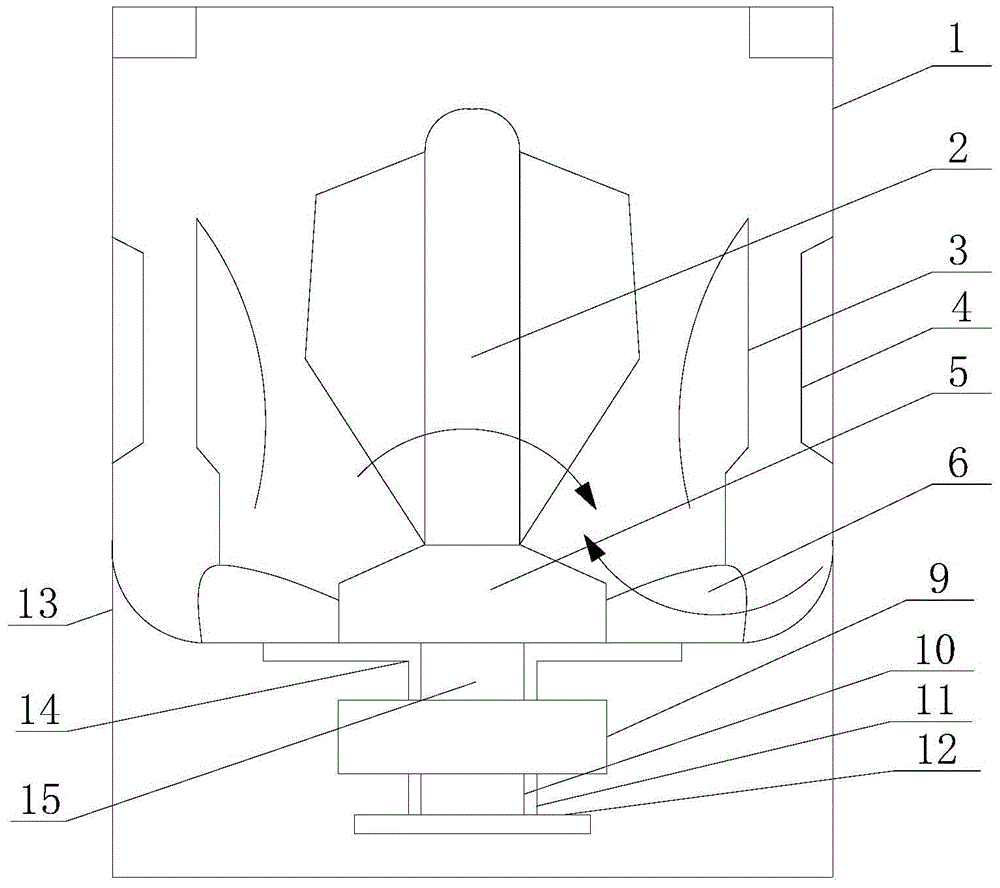

[0051] Such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the shoe washing machine of this embodiment includes a water tub 1 and an inner pulsator 5 and an outer pulsator 6 respectively arranged inside the water tub 1. The inner pulsator 5 is rotatably arranged at the bottom of the water tub 1. At the central position, the outer pulsator 6 is rotatably arranged on the periphery of the inner pulsator 5; the direction of the outer pulsator 6 is opposite to that of the inner pulsator 5 in the washing state, and the inner pulsator 5 is provided with a central brush 2 , the inner wall of the bucket 1 is provided with a bucket wall brush 4 .

[0052] In order to further improve the washing effect of the shoe washing machine of the present invention on the shoes, the outer pulsator 6 of the present invention is detachably installed with a shoe rack 3 for placing shoes, and the shoe rack 3 and the outer pulsator 6 rotate integrally. The shoe rack 3 of the present inv...

Embodiment 2

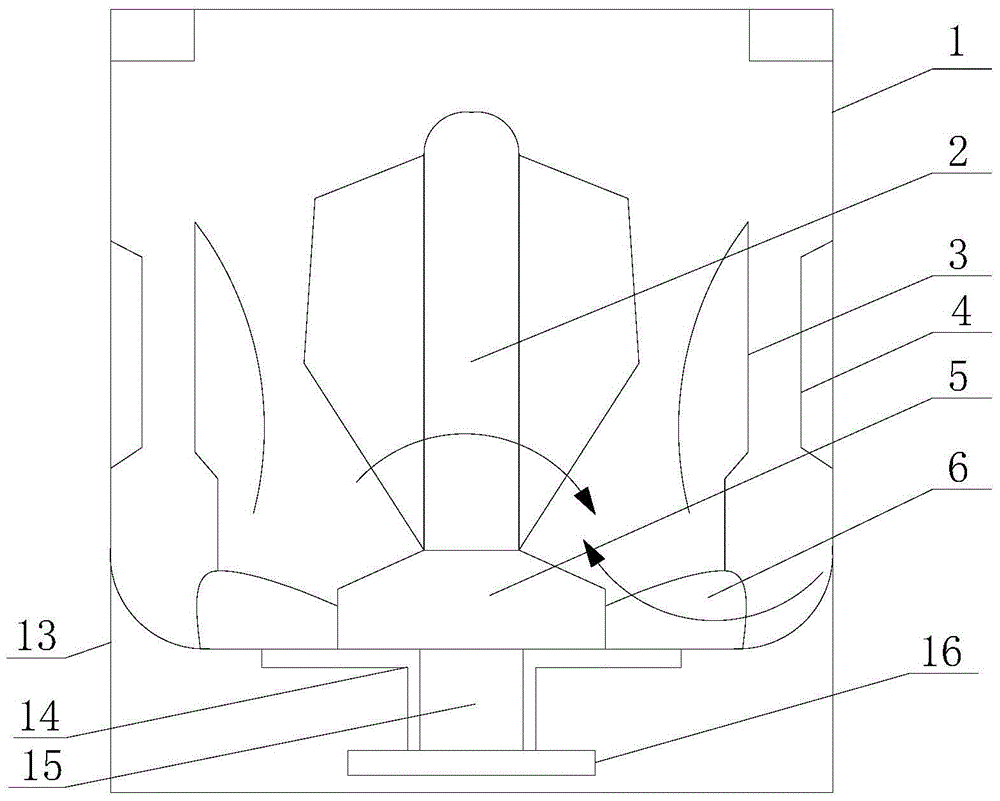

[0063] The shoe washing machine of this embodiment includes a bucket 1 and an inner pulsator 5 and an outer pulsator 6 respectively arranged inside the bucket 1 , and the inner pulsator 5 is rotatably arranged at the center of the bottom of the bucket 1 The outer pulsator 6 is rotatably arranged on the periphery of the inner pulsator 5; the turning of the outer pulsator 6 and the inner pulsator 5 in the washing state is opposite, and the inner pulsator 5 is provided with a central brush 2 and a water bucket The barrel wall brush 4 is set on the inner wall of 1.

[0064] Such as Figure 8 As shown, the central brush 2 of this implementation is detachably installed on the inner pulsator 5, and the disassembly and installation method mainly has the following advantages:

[0065] (1) In the washing state, the central brush 2 is mounted on the inner pulsator 5; in the dehydration state, the central brush 2 is disassembled from the inner pulsator 5.

[0066] In this way, the centr...

Embodiment 3

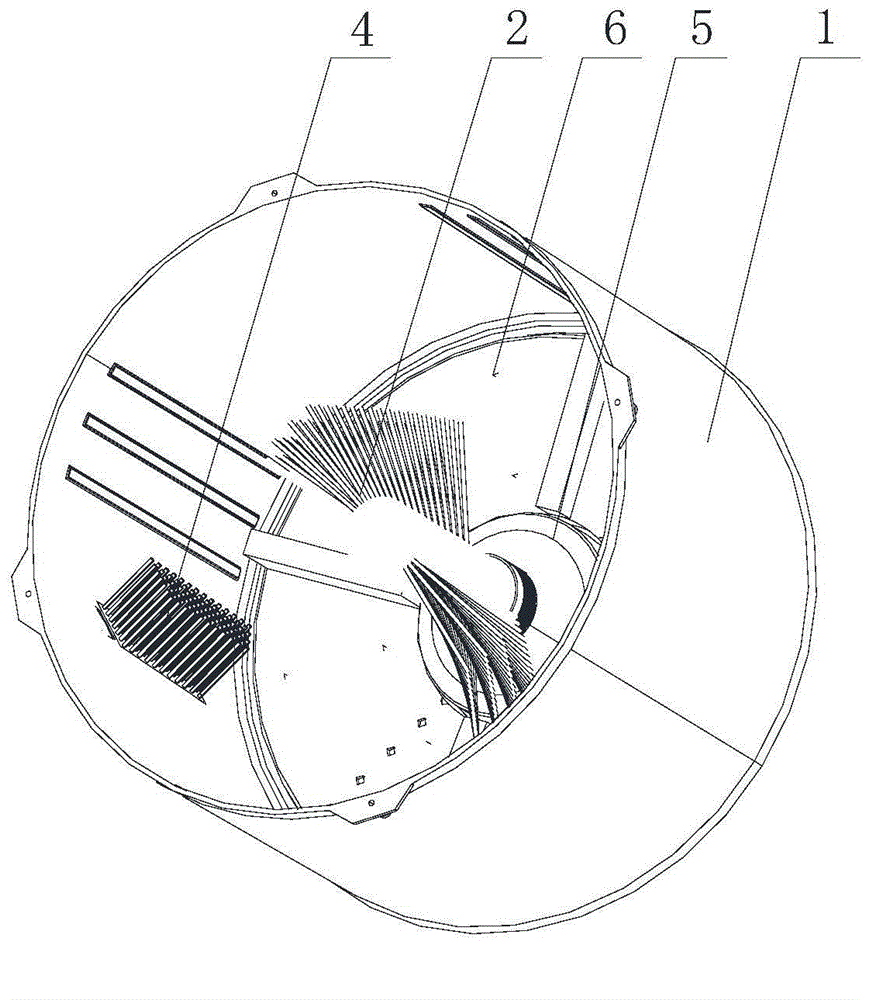

[0075] The shoe washing machine of this embodiment includes a bucket 1 and an inner pulsator 5 and an outer pulsator 6 respectively arranged inside the bucket 1 , and the inner pulsator 5 is rotatably arranged at the center of the bottom of the bucket 1 The outer pulsator 6 is rotatably arranged on the periphery of the inner pulsator 5; the turning of the outer pulsator 6 and the inner pulsator 5 in the washing state is opposite, and the inner pulsator 5 is provided with a central brush 2 and a water bucket The barrel wall brush 4 is set on the inner wall of 1.

[0076] The central hairbrush 2 of this implementation comprises a cylinder 201 and a central bristle 202, such as Image 6 As shown, the central bristles 202 are arranged on the cylinder 201 in a spiral shape, so that the central bristles 202 can better contact with the upper of the shoes on the shoe rack 3, and the cleaning effect of the central bristles 202 can be improved. Such as Figure 7 As shown, the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com