Screen filter capable of recycling pollution discharge water and achieving automatic cleaning

A mesh filter, automatic cleaning technology, applied in the direction of fixed filter element filter, membrane filter, filtration and separation, etc., can solve the problems of low degree of automation and high energy consumption, achieve energy saving effect, high work efficiency, less parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

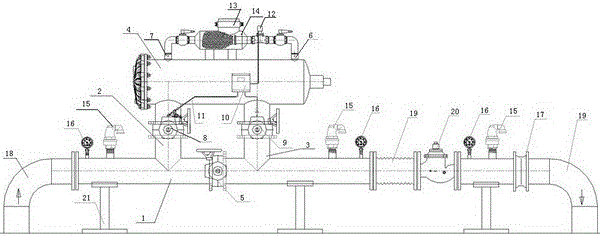

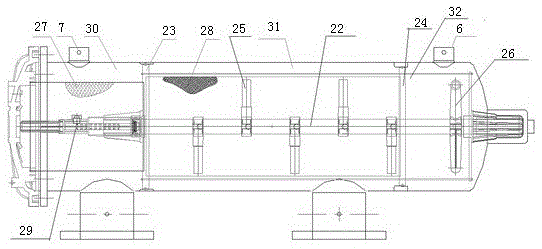

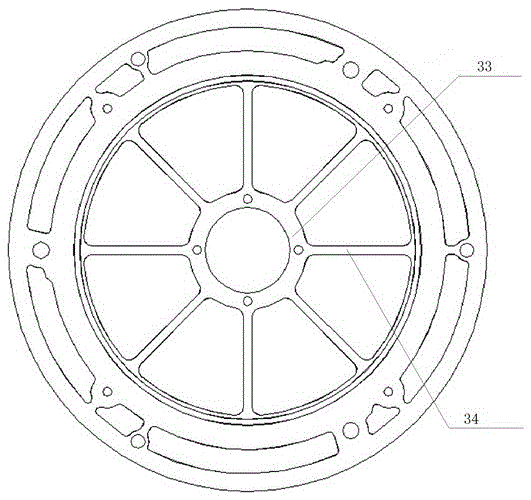

[0010] A kind of waste water recycling and reuse automatic cleaning screen filter, such as figure 1 , figure 2 As shown, on the horizontal water supply pipe 1, the horizontal filter tank 4 is connected with the water inlet and outlet pipes 2 and 3 provided, and the first maintenance valve 5 is installed on the water supply pipe 1 between the water inlet and outlet pipes 2 and 3, In the horizontal filter tank 4, the horizontal filter tank 4 is sequentially divided into a coarse filter cavity 30 equipped with a coarse filter screen 27, a fine filter cavity 31 equipped with a fine filter screen 28, and a hydraulic torsion force through a hollow partition 23 and a partition plate 24. cavity 32, the water inlet pipe 2 is connected to the coarse filter cavity 30, and the outlet pipe 3 is connected to the fine filter cavity 31, and the drive shaft 22 is installed through a shaft sleeve in the horizontal filter tank 4, and is located on the drive shaft 22 of the coarse filter cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com