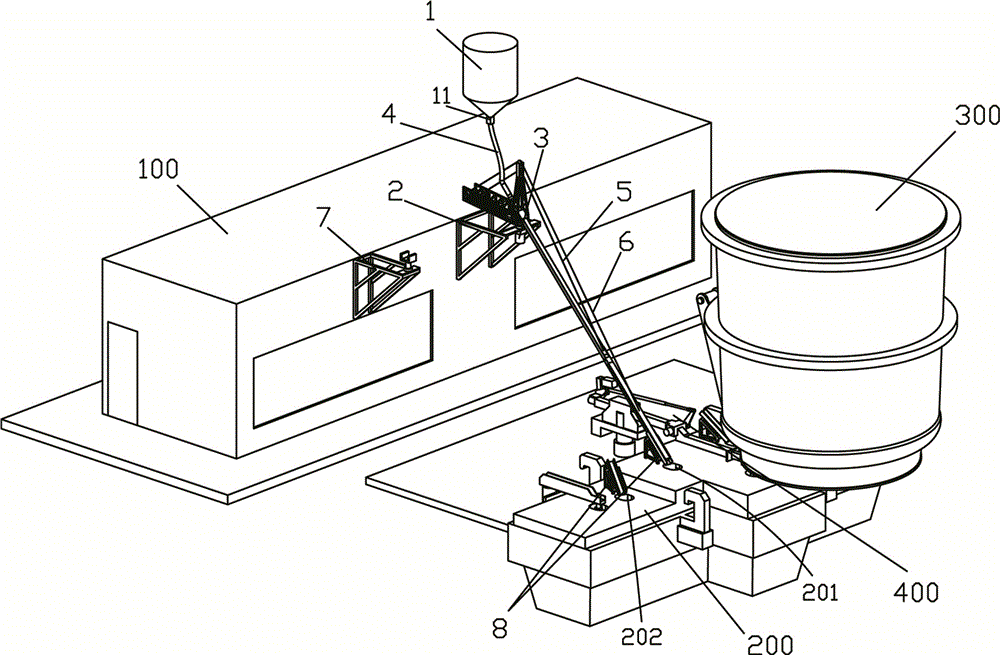

Tundish covering agent feeding device and method

A technology of feeding device and covering agent, which is applied in the field of tundish covering agent feeding device, can solve the problems of reliable hose long-distance conveying and easy jamming, complex surrounding structure of tundish area, large discrete addition amount of single hole, etc. Reduce manual work intensity, avoid device deformation and aging, and improve the effect of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

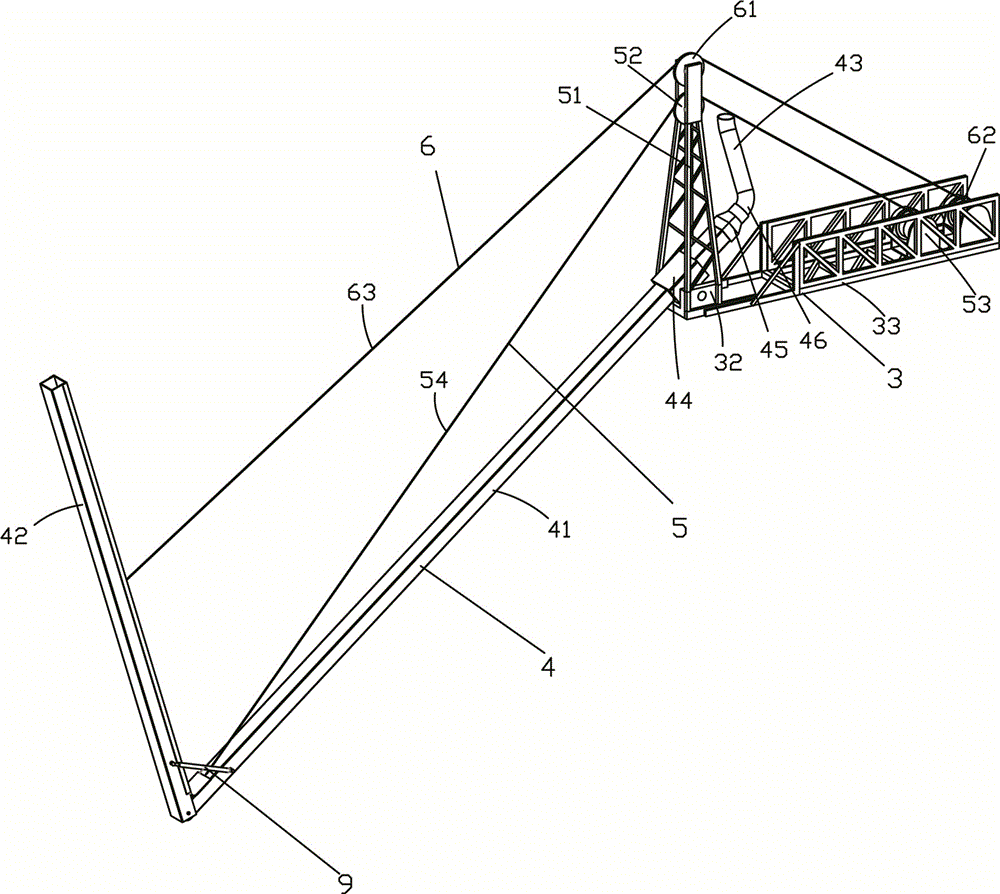

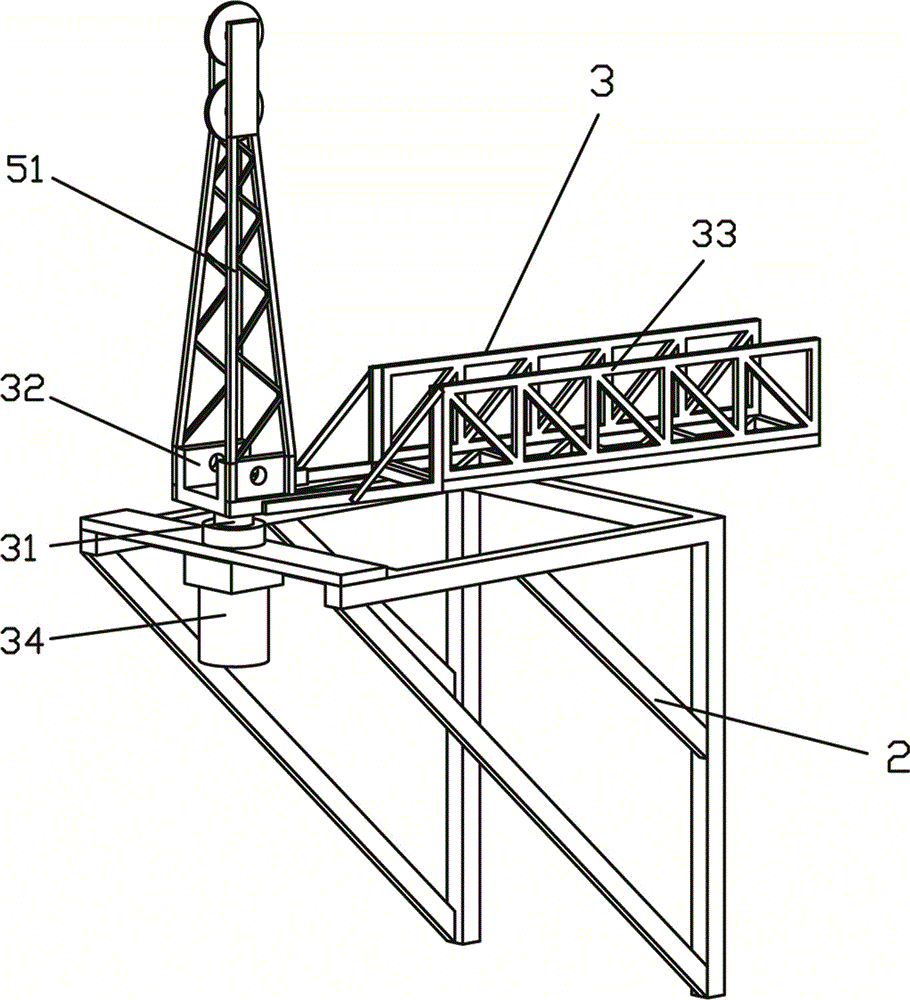

[0067] When the feeding operation is not performed, the device is in a standby state, and at this time, the space between the second straight pipe and the first straight pipe is in a straight state. The front end of the first straight pipe is placed on the support frame of the standby position. Preferably, the first and second straight pipes are placed in a horizontal plane, parallel to the sideline of the operating room.

[0068] Before the feeding operation starts, the material tube rack is quickly positioned by being close to the positioning groove on the tundish cover, and each material tube rack is placed in place in turn.

[0069] When the feeding operation starts, the first motor drives the first reel to shrink the first wire rope to lift the front end of the first straight pipe, and then the second motor drives the vertical rotary shaft to make the first and second straight pipes rotate and leave the standby position.

[0070] The pitch adjustment mechanism and the sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com