Route inspection robot walking mechanism

A technology for inspection robots and walking mechanisms, applied in the directions of manipulators and manufacturing tools, can solve the problems of inconvenient maintenance, lack of up and down driving and sharp turning steering functions, etc., to achieve easy installation and unloading maintenance, simple and reliable driving methods, The effect of stabilizing the drive and braking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

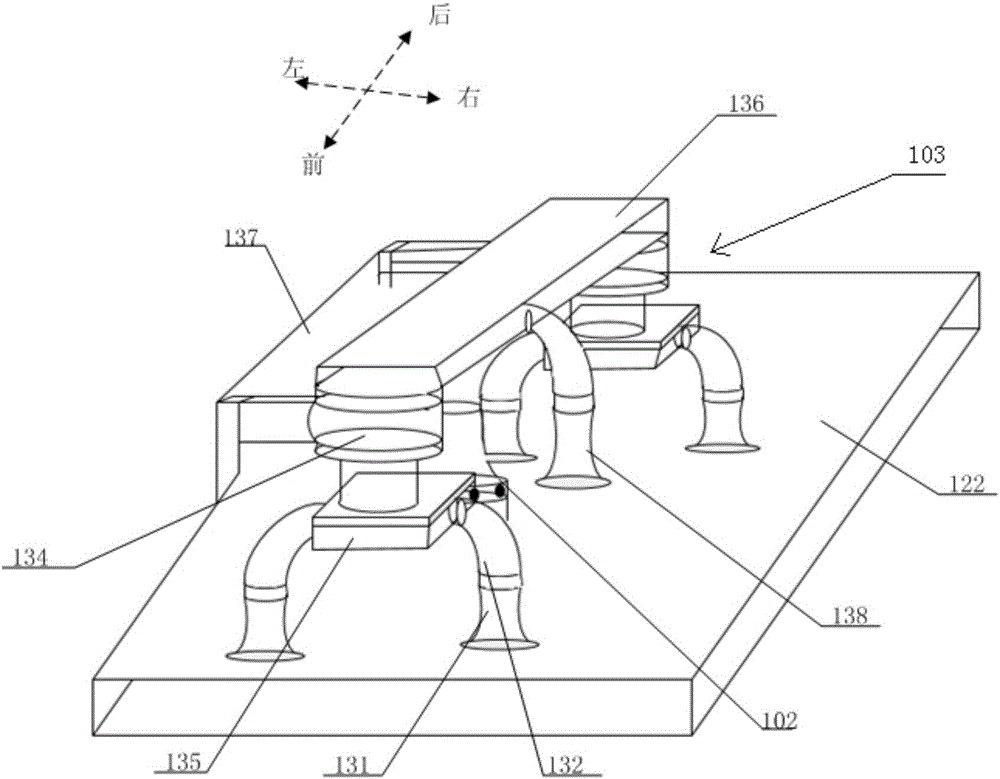

[0021] The walking mechanism of the inspection robot provided by the present invention has the functions of stable walking on slopes and steering in sharp turns, and includes a driving mechanism 102 and a guiding mechanism 103 .

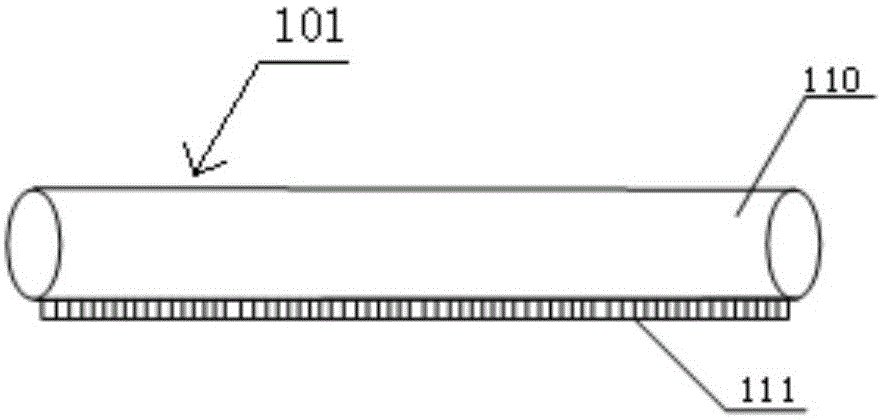

[0022] Such as figure 1 As shown, the aluminum alloy track 101 is composed of a main rail 110 with a circular cross section and a rack 111 installed under the main rail 110 , and the track may have ramps and bends according to the direction of the tunnel.

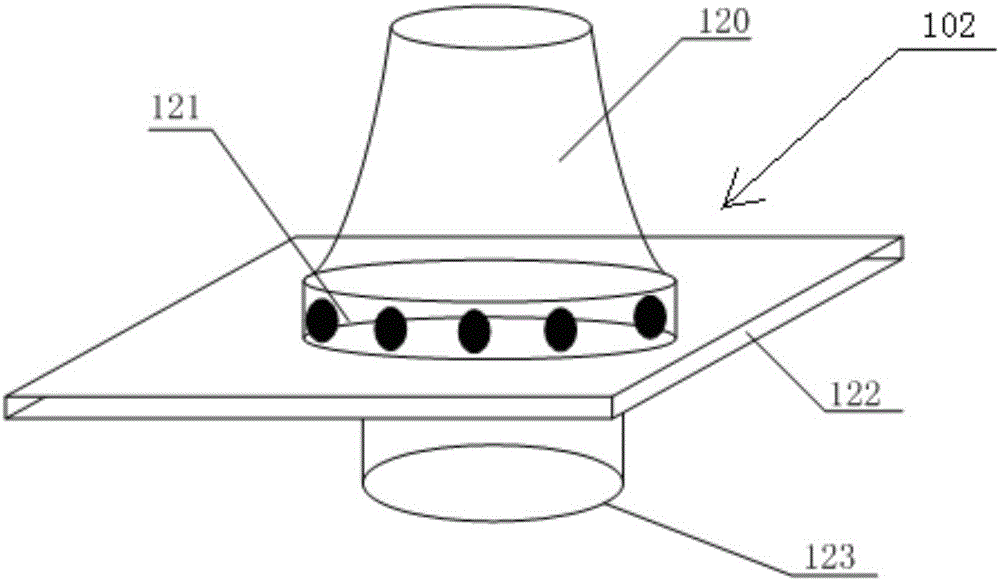

[0023] Such as figure 2 As shown, the driving mechanism 102 includes a bearing plate 122, a driving motor 123, a gear 121, and a track fitting 120. The driving motor 123 is installed below the loading plate 122, and the gear 121 and the track fitting 120 are installed sequentially above the loading plate 122. , the motor shaft of the driving motor 123 passes through the bearing plate 122 and is coaxially connected with the gear 121 and the track fitting 120, and the driving motor 123 synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com