Self-adaptive knife holder and self-adaptive method for edge trimming of ultra-soft metal foil

A metal foil strip and self-adaptive technology, applied in metal processing and other directions, can solve the problems of easy tearing of metal foil strip, non-continuous processing, low hardness, etc., and achieve the effect of solving online measurement problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

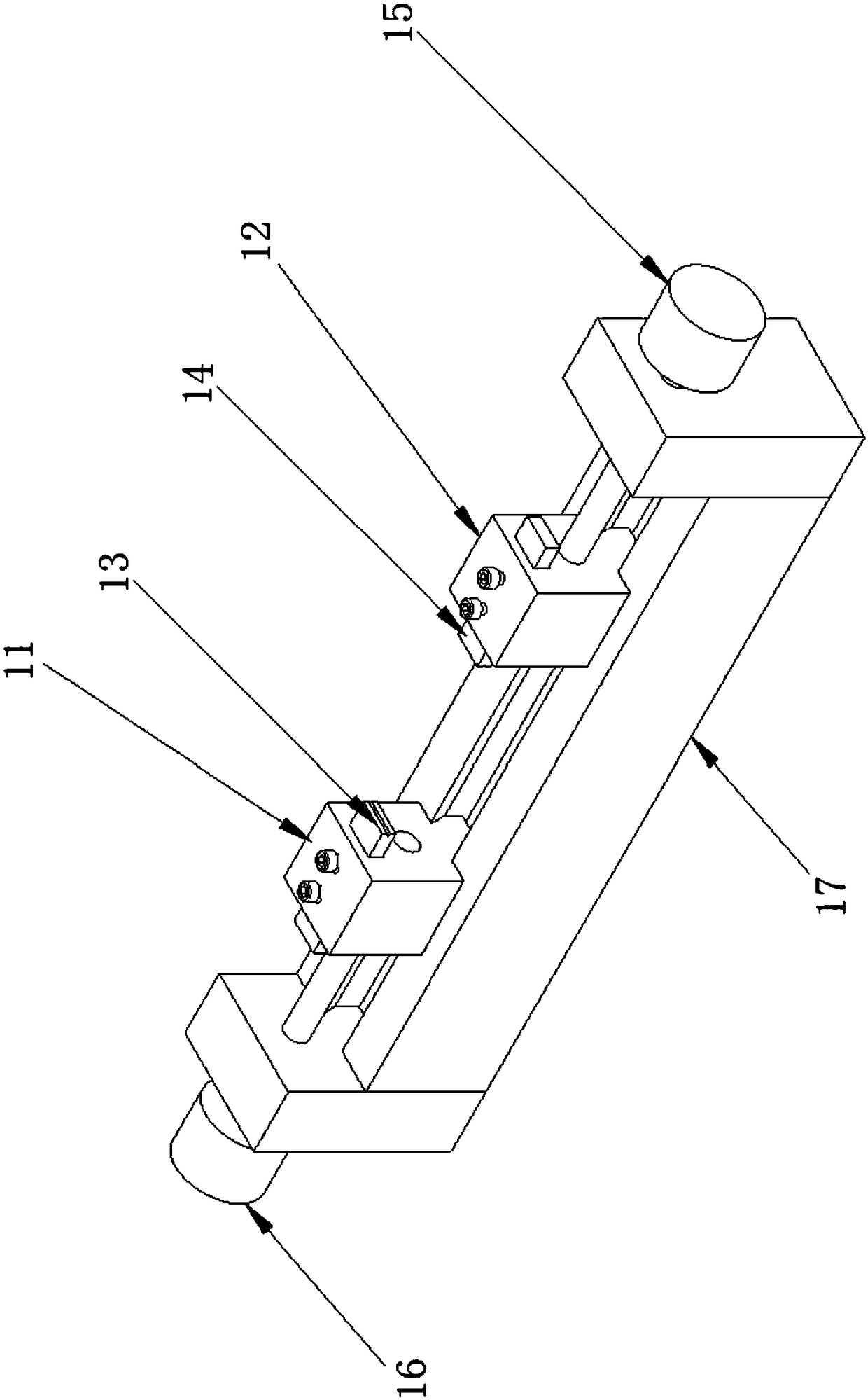

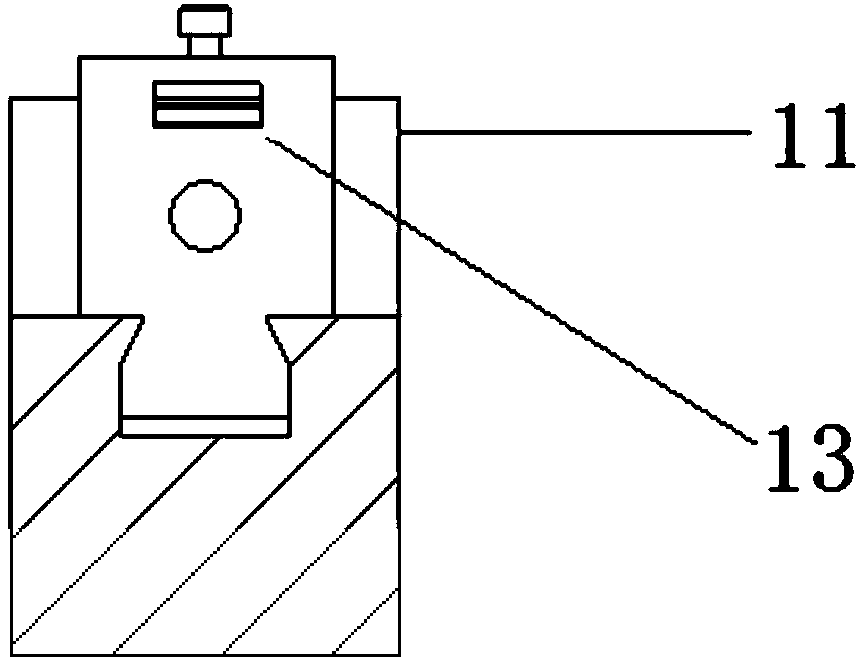

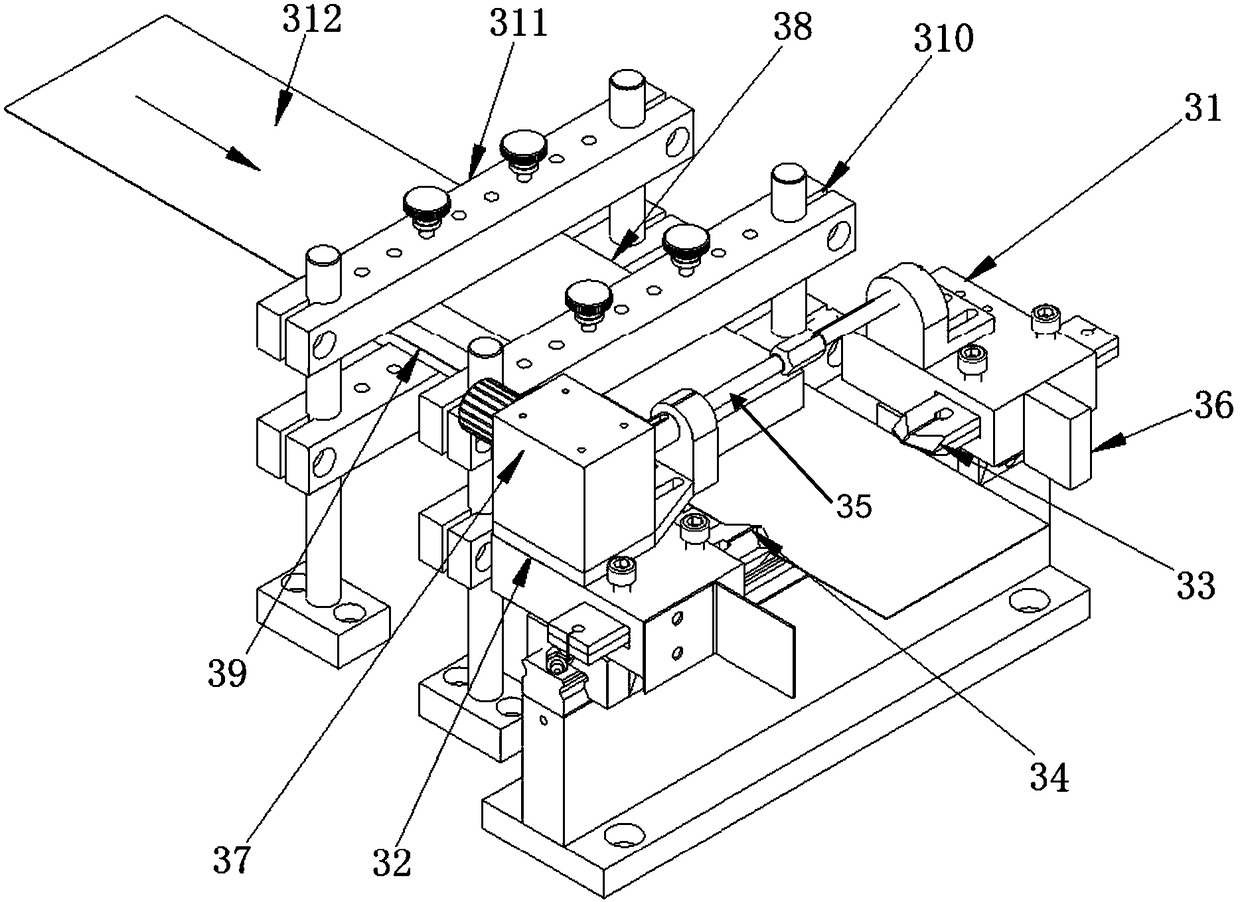

[0025] The invention discloses a self-adaptive knife holder for super-soft metal foil belt trimming, which is applied to a super-soft metal foil self-adaptive trimming machine. The main components of the trimming machine include a plurality of ultra-soft metal foil strip edge trimming self-adaptive tool holders (adaptive tool holder assembly) of the present invention, a plurality of equal high pressure plate assemblies, a machine table, a feeding device, and a receiving device . Multiple self-adaptive knife rest assemblies and multiple equal-high pressure plate assemblies are arranged in parallel and set on the machine table, and the self-adaptive knife rest assemblies and equal high-voltage plate assemblies are set at intervals, and the feeding device and receiving device are set on both sides of the machine table.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com