On-line measurement method and measurement device for viscosity of hydrocarbon fuel high temperature and high pressure cracking products

A hydrocarbon fuel and cracking product technology, applied in the field of viscosity measurement method and supporting measuring device of hydrocarbon fuel cracking product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

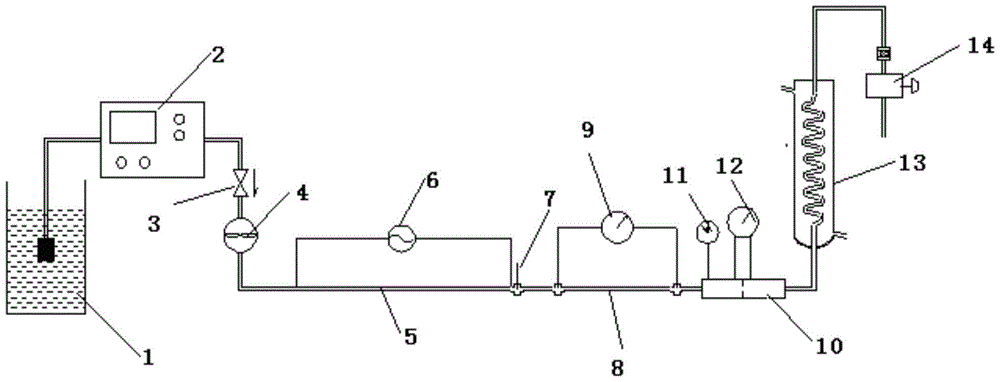

[0054] In this embodiment, the structure of the on-line measurement device for the viscosity of the high-temperature and high-pressure cracking product of the hydrocarbon fuel is as follows: figure 1 As shown, it includes an oil storage tank 1, a high-pressure constant-flow pump 2, a mass flow meter 4, a heating pipe 5, a pressure gauge 11, a viscosity measuring pipe 8, an orifice plate pressure collector 10 equipped with a second differential pressure transmitter 12, A condenser 13 and a back pressure valve 14; the liquid inlet end of the high-pressure constant-flow pump 2 is connected to the oil storage tank 1 through a pipe fitting, and the liquid outlet end of the high-pressure constant-flow pump 2 is connected to the liquid inlet of the mass flow meter 4 through a pipe fitting , a check valve 3 that prevents the hydrocarbon fuel from flowing back to the high-pressure constant-flow pump is arranged on the pipe fitting connecting the outlet end of the high-pressure constant-...

Embodiment 2

[0057] In this embodiment, the flow field coefficient A of the capillary is calibrated, and the steps are as follows:

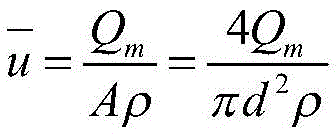

[0058] Calibrate with nitrogen with a purity of 99.99%, look up the viscosity and density of nitrogen in the table, pass nitrogen into the online measuring device with the structure described in Example 1, adjust different temperatures, and measure the mass flow Q of nitrogen m and the differential pressure Δp at both ends of the viscosity measuring tube 8 at different temperatures, the viscosity, density and mass flow Q of the measured nitrogen gas m , differential pressure Δp into the following formula:

[0059] Calculate the value of A, and the calculation results are shown in Table 1. Take the average of multiple measurements It is used to measure the viscosity of aviation kerosene pyrolysis products under high temperature and high pressure.

[0060] Table 1 Calibration of thin tube flow field coefficient A

[0061]

[0062] Note: 1. In the onli...

Embodiment 3

[0065] In this example, the measuring device with the structure described in Example 1 and the capillary flow field coefficient calibrated in Example 2 are used to measure the viscosity of aviation kerosene high-temperature and high-pressure cracking products online.

[0066] Hydrocarbon fuel: aviation kerosene;

[0067] mass flow Q m : 1g / s;

[0068] Cracking pressure p: 1.0MPa;

[0069] Viscosity measurement tube inner diameter: 2mm; length: 20cm;

[0070] Inner diameter of heating tube: 2mm, length: 100cm;

[0071] Cracking temperature: see Table 2.

[0072] The specific operation steps are as follows:

[0073] ① Turn on the high-pressure constant-flow pump 2, so that the hydrocarbon fuel to be measured enters the heating tube 5 according to the set mass flow rate, and uses the mass flow meter 4 to measure the mass flow rate Q of the hydrocarbon fuel m ;

[0074] ② Turn on the AC power supply 6 of the heating tube 5, adjust the cracking temperature and cracking press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| cracking temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com