Whitening process of veneer/square

A technology of veneer and craftsmanship, used in wood processing appliances, wood treatment, manufacturing tools, etc., can solve the problems of soft touch, poor hand feel, complicated process, etc., and achieve the effect of increasing flatness, wide application and comfortable hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

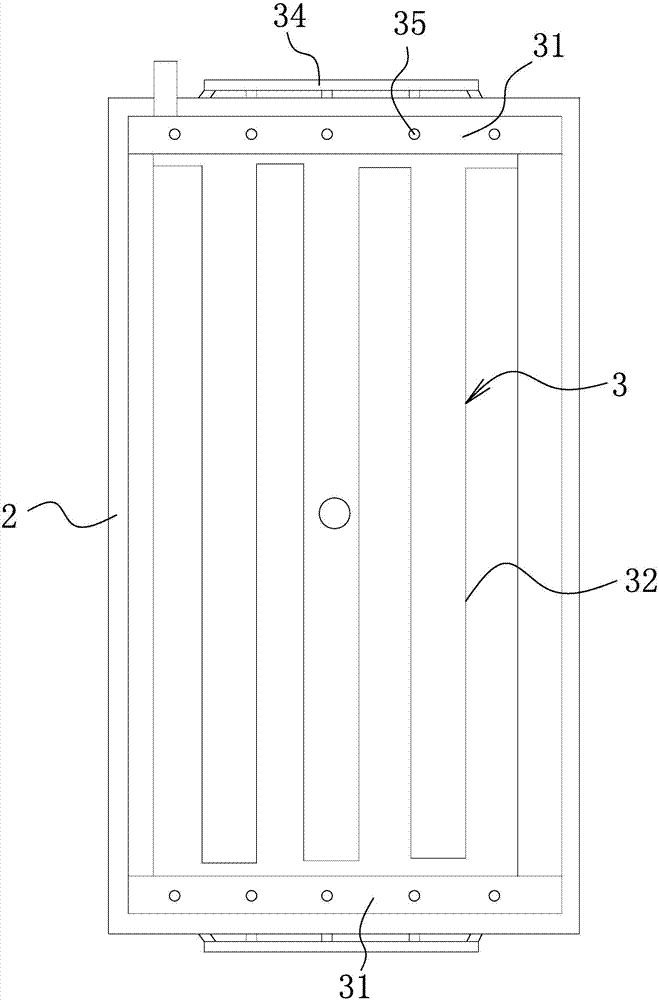

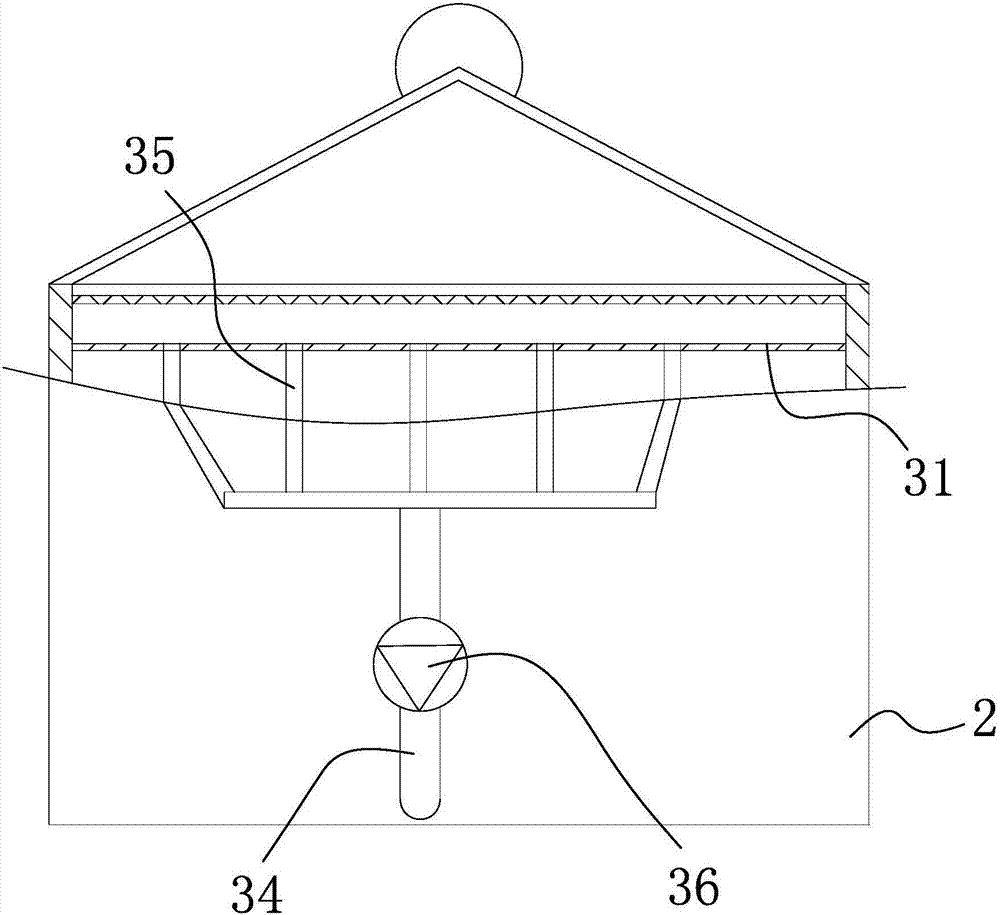

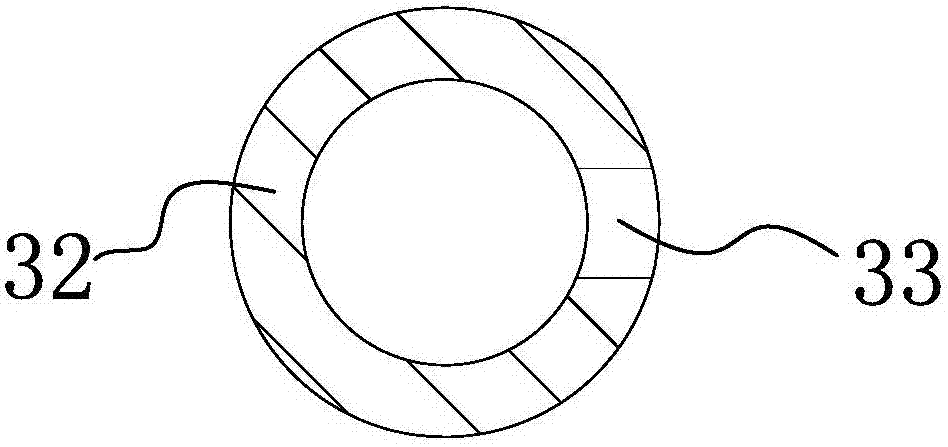

[0057] Such as Figure 4-5 with Figure 7 As shown, the cage 1 includes a rectangular cage body 11 with an opening, and a closing cover 12 capable of closing the opening, and a locking cover 12 is provided between the rectangular cage body 11 and the closing cover 12. The locking structure on the rectangular cage body 11 is provided with plastic partitions 13 that are respectively in a vertical state when the rectangular cage body 11 is placed in the dyeing vat 2 in the rectangular cage body 11. The rectangular cage body 11 is a The side is provided with several suspension rings 17.

Embodiment 2

[0059] Such as Image 6 Shown, hanging cage 1 comprises the square cage body 14 that has opening, is provided with some pumping boxes 15 in square cage body, and described pumping box 15 is vertically arranged when square cage body is placed in dye vat 2, in square cage body One side of the body 14 is provided with several lugs 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com