Integral inlaying type ventilation steel die

A vapor-permeable steel and mosaic technology, which is applied in the field of integral mosaic-type vapor-permeable steel molds, can solve the problems of inability to carry out large-scale industrial production, long molding time, and low product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

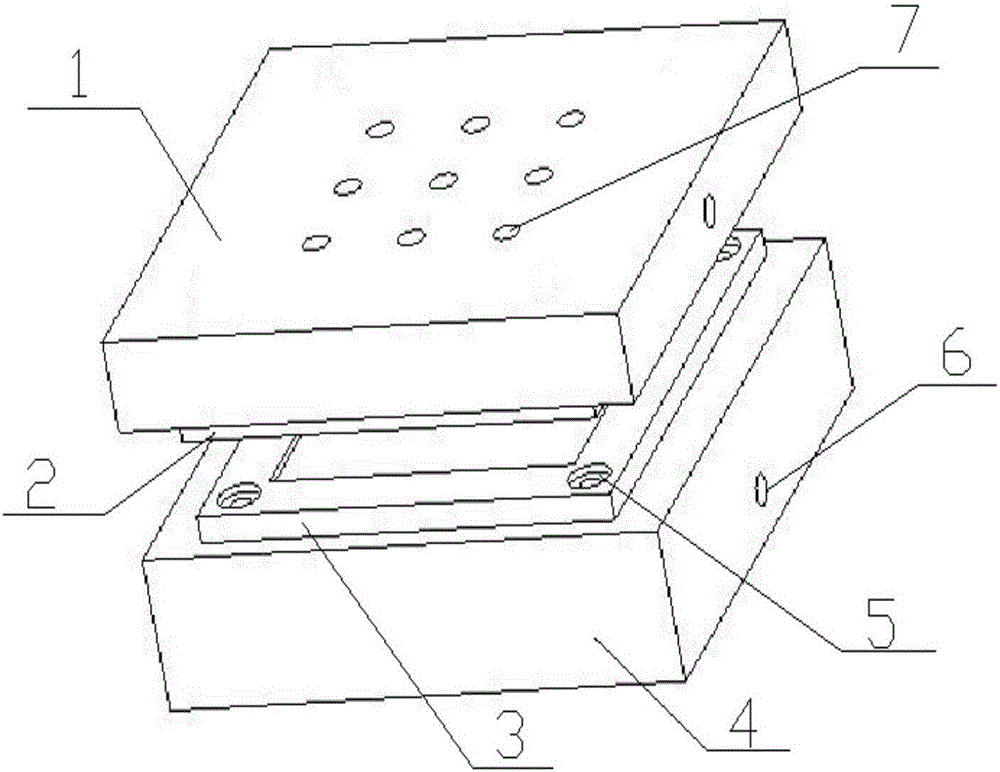

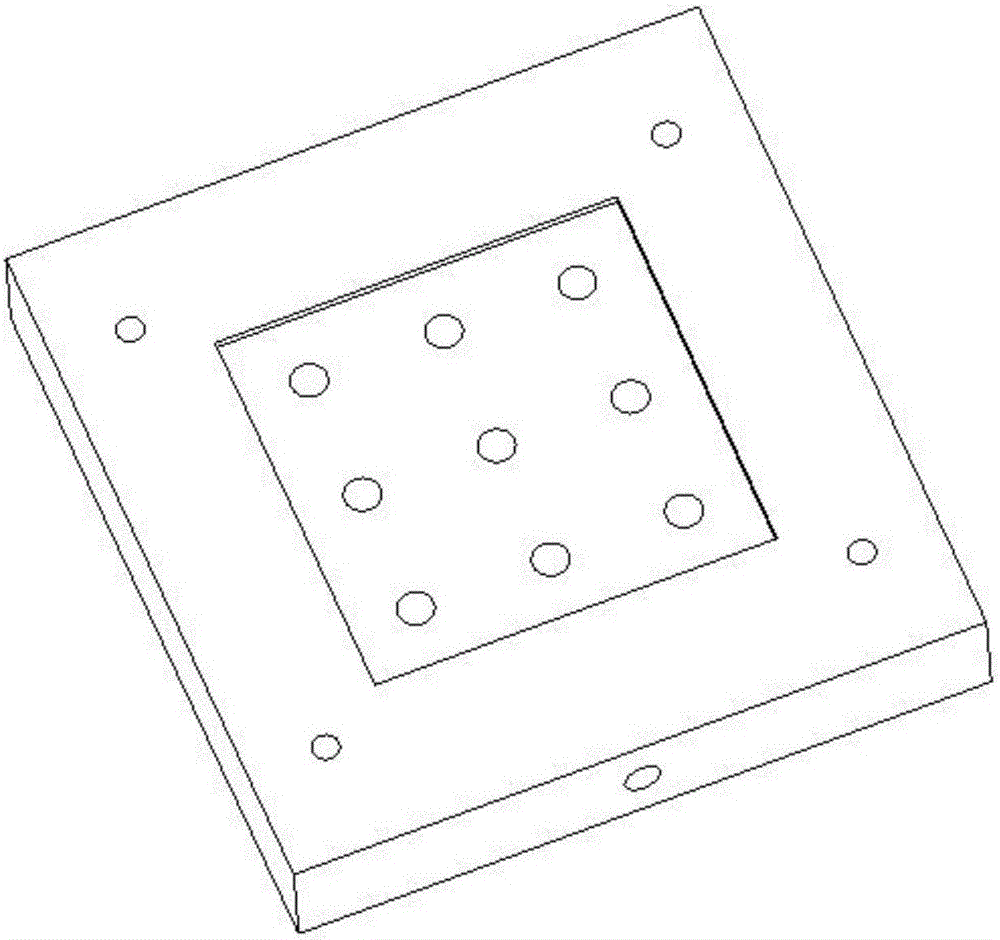

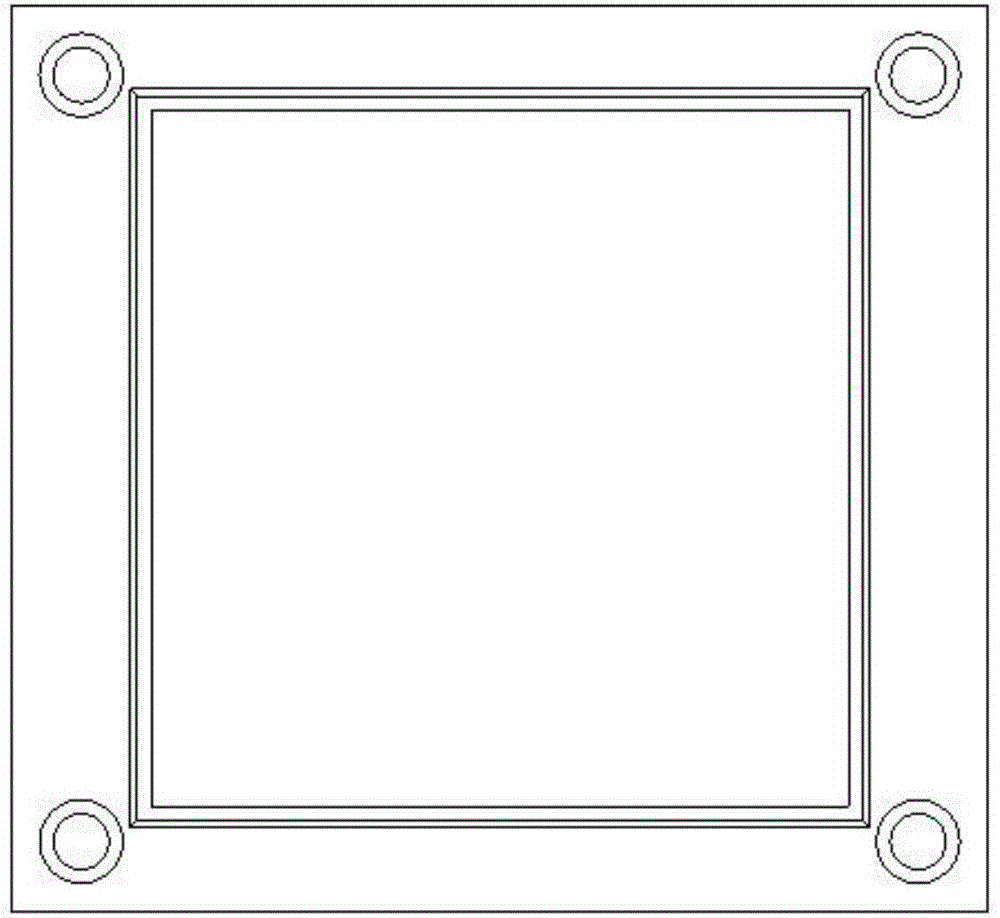

[0022] Below in conjunction with accompanying drawing, the present invention / invention are described in detail as follows:

[0023] Such as Figure 1-5 As shown, an integral mosaic type steam-permeable steel mold includes mosaic base upper mold 1, vapor-permeable steel upper mold 2, vapor-permeable steel lower mold 3, mosaic base lower mold 4, link bolt holes 5, temperature sensor installation Hole 6, vent hole 7. The integral mosaic adopts bolt connection, which is easy to disassemble and easy to clean and maintain the mould. Convex wedges are designed for the upper die of vapor-permeable steel, and corresponding concave cavities are designed for the lower die of vapor-permeable steel. The wedge-shaped automatic positioning structure formed in this way can realize the precise positioning of the upper and lower dies.

[0024] Among them: the material of the upper and lower molds of the inlaid base is a cheap metal material (such as aluminum alloy, magnesium alloy, mold steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com