New energy vehicle parts handling detachable tooling and handling method

A new energy vehicle and dismantling tooling technology, which is applied in the direction of transportation and packaging, manual conveying devices, conveyors, etc., can solve the problems of lower production efficiency, large space occupied by transfer racks, inconvenient transfer operation of transfer racks, etc., to improve loading Efficiency of parts, convenient transportation, and the effect of meeting transshipment needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

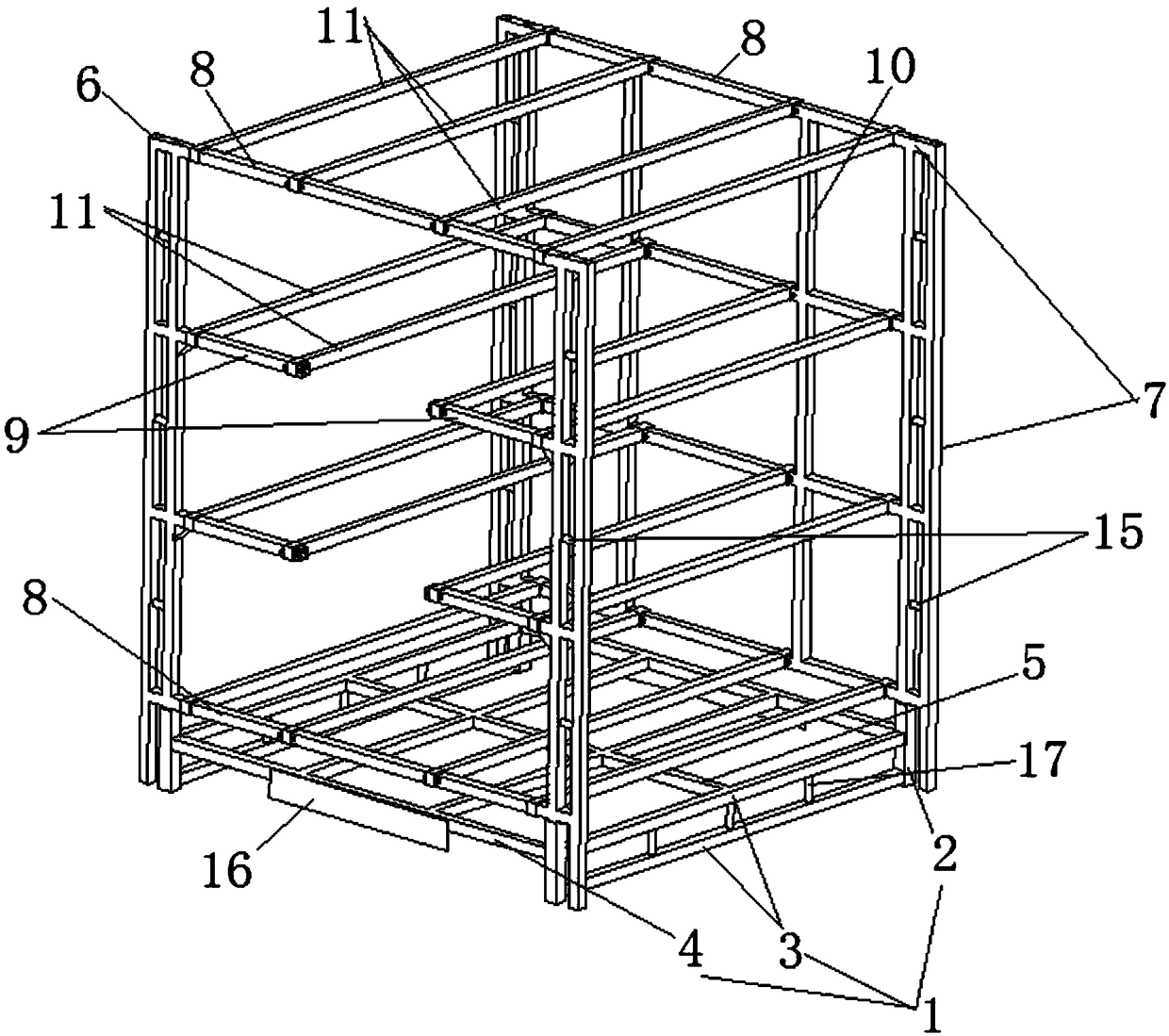

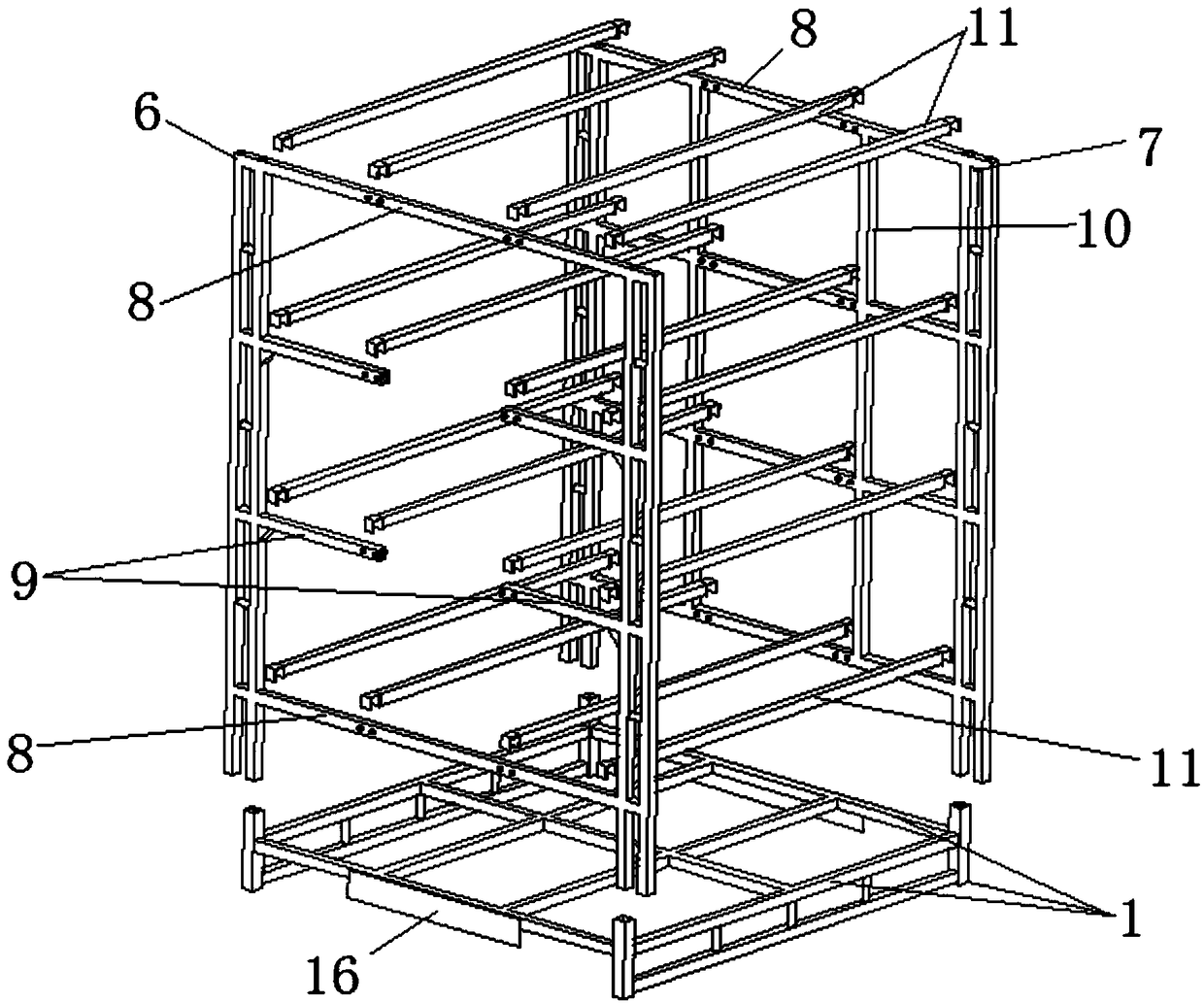

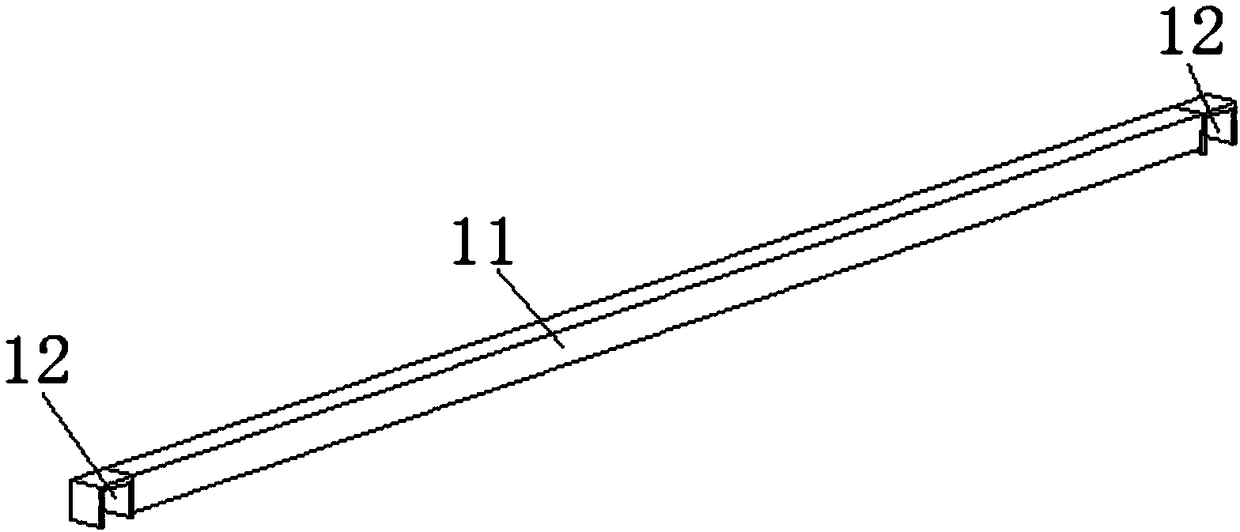

[0024] Such as figure 1 and figure 2 As shown, this kind of detachable tooling for the handling of new energy automobile parts includes a square base 1, hollow columns 2 are provided on the four corners of the base 1, and two parallel sides of the four sides of the base 1 are provided with connecting The double-layer crossbar 3 on the hollow column 2, the other parallel side of the four sides of the base 1 is provided with a single-layer crossbar 4 connected to the hollow column 2, and the middle part of the single-layer crossbar 4 is provided with a guide plate 16. The upper-layer cross-bar of the double-layer cross-bar 3 and the single-layer cross-bar 4 are connected by reinforcing beams 5, and the reinforcing beams 5 are intersected to improve the structural strength of the base 1; inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com