Structure of reinforced soil sewer supported by bored concrete piles of mini steel tubes

A technology of cast-in-situ piles and reinforced soil, which is applied in the direction of foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of long construction period, high cost, and long construction period, and achieve less construction site occupation, good construction safety, Apply low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

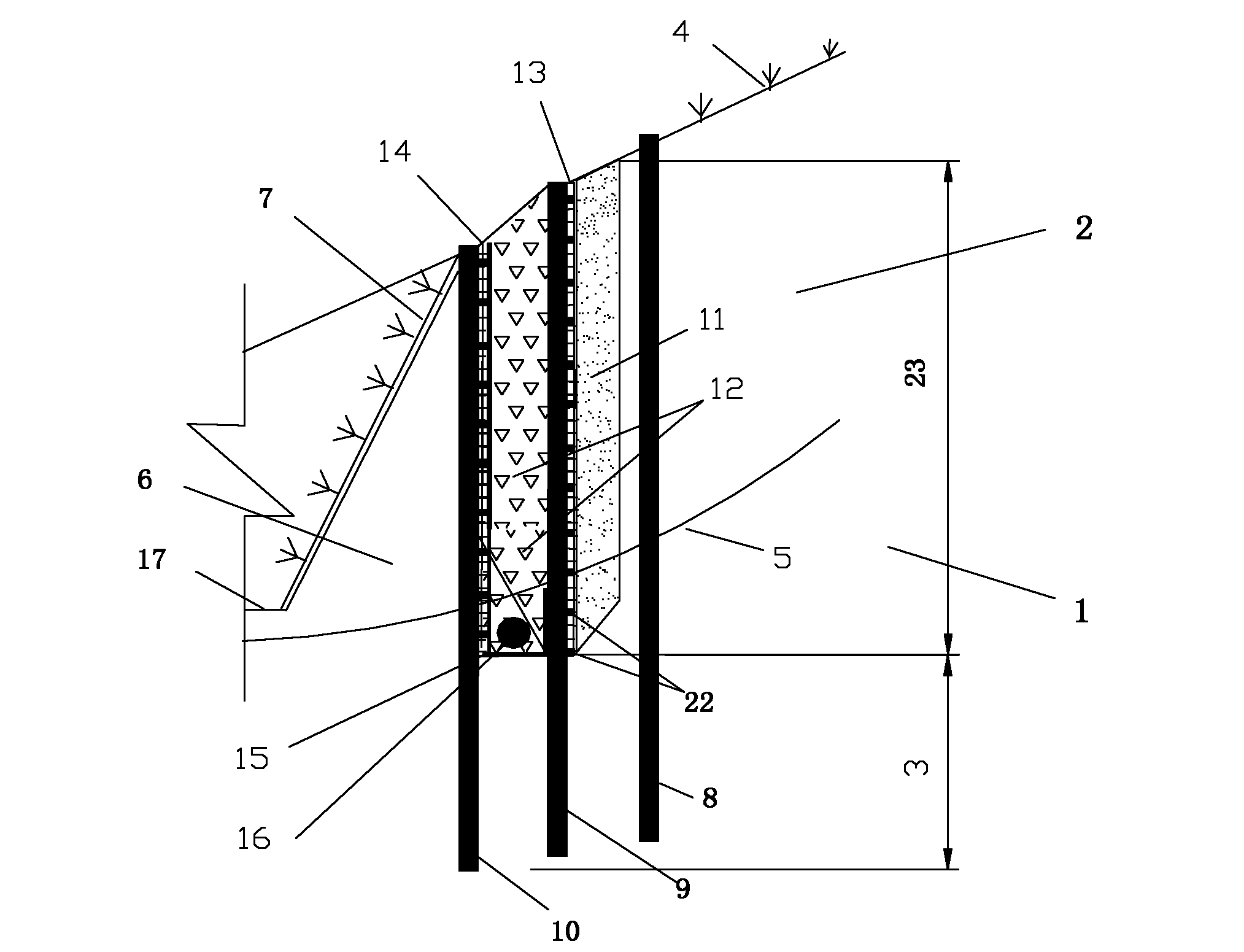

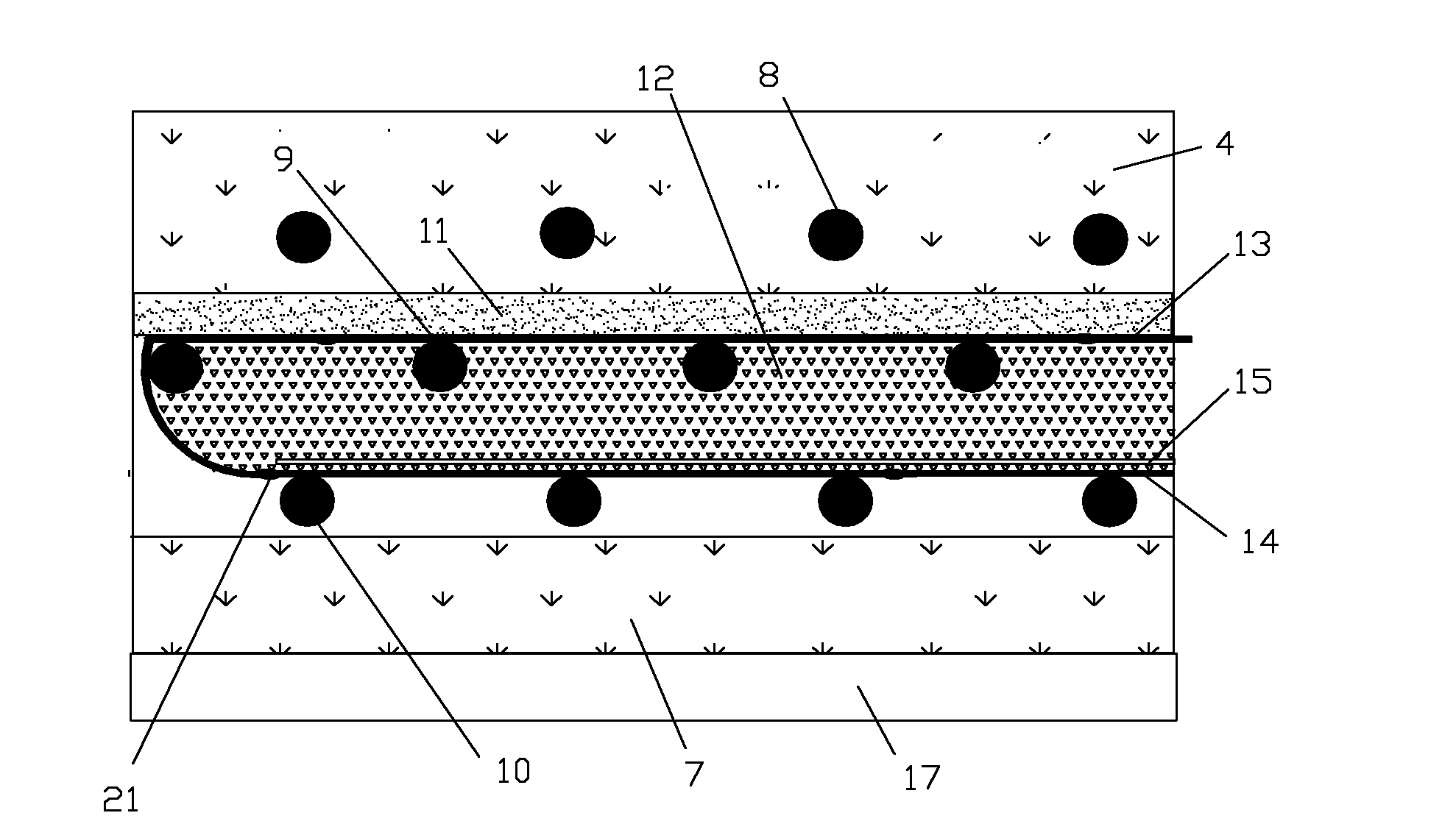

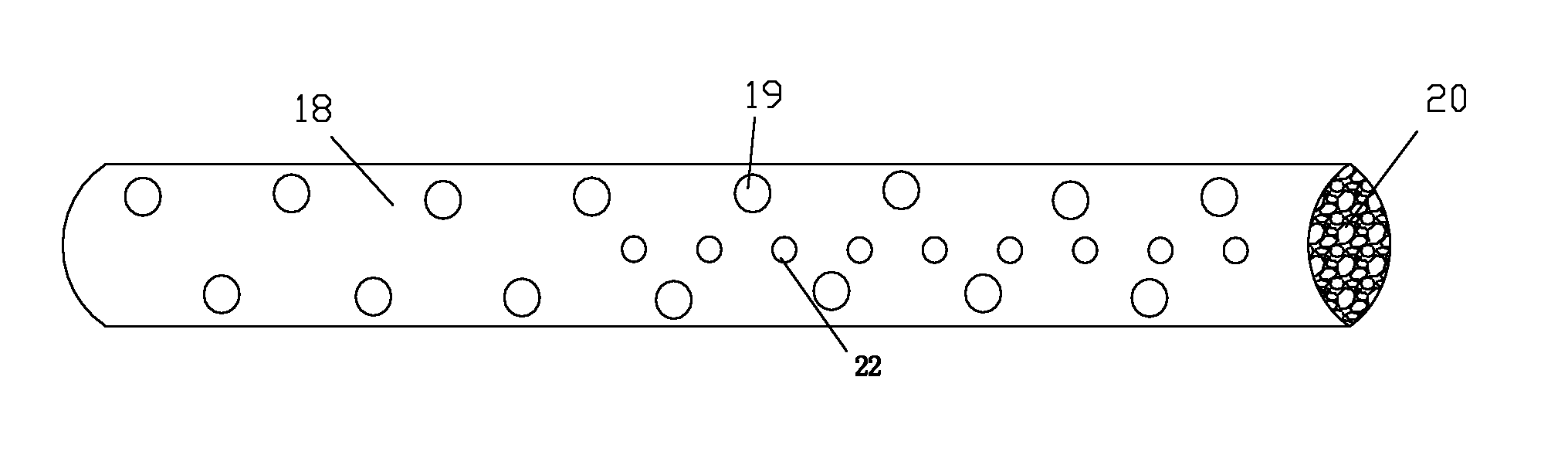

[0016] see figure 1 , figure 2 , image 3 and Figure 4 , a sliding surface 5 is formed between the landslide body 2 and the bedrock 1 of the non-landslide body, along the landslide body 2 from top to bottom, the first row of miniature Steel pipe cast-in-place piles 8, the second row of micro steel pipe cast-in-place piles 9 and the third row of micro steel pipe cast-in-place piles 10, the first row of micro steel pipe cast-in-place piles 8, the second row of micro steel pipe cast-in-place piles 9 and the third row of micro steel pipe cast-in-place piles 10 An anchorage section 3 is formed in the bedrock 1, and a reinforced soil seepage ditch 23 is excavated in the upper part between the first row of micro-steel pipe cast-in-place piles 8, the second row of micro-steel pipe cast-in-place piles 9 and the third row of micro-steel pipe cast-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com