An automatic winding machine dual-channel intubation device and intubation method

An automatic winder and intubation technology, which is applied in the directions of transportation and packaging, thin material handling, and transportation of filamentous materials, etc., can solve the problems of intubation capacity restricting the overall efficiency, unacceptable to textile enterprises, and high use and maintenance costs. , to achieve the effect of simple structure, reduced manufacturing cost and improved intubation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

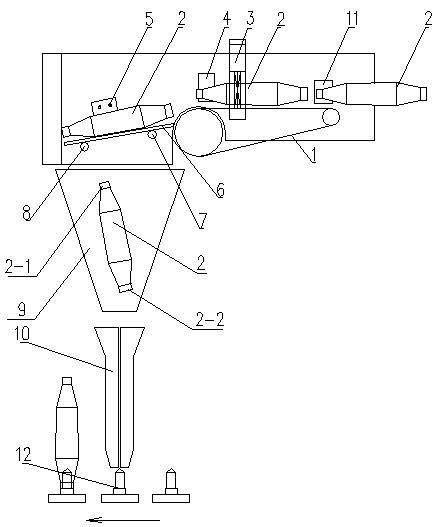

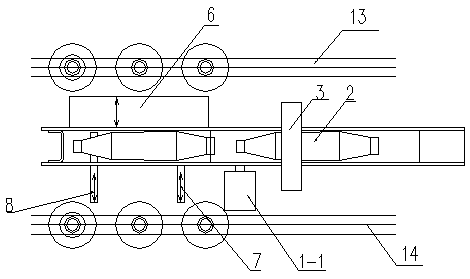

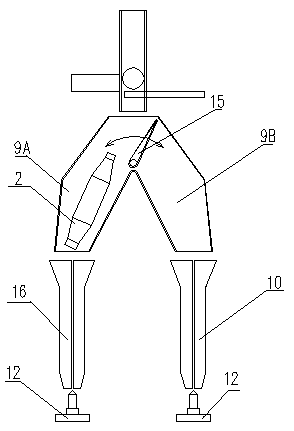

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] see Figure 1-Figure 4 , a two-way intubation device for an automatic winder of the present invention, comprising a bobbin conveying device, a bobbin size judgment device, a bobbin releasing device arranged near the output end of the bobbin conveying device, a two-way guiding and positioning device, The first tray channel 13 and the second tray channel 14 , the two-way guiding and positioning device includes an upper funnel 9 , a first lower funnel 16 and a second lower funnel 10 . The upper funnel 9 is a three-way pipe structure, the top of the upper funnel 9 is a bobbin inlet, the lower part of the upper funnel 9 is bifurcated into the first row of bobbin pipes 9A and the second row of bobbin pipes 9B, the first row of bobbins The lower ports of the pipeline 9A and the second row of bobbin pipelines 9B are respectively aligned with the upper ports of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com