Cyclic diol modified water-based polyisocyanate curing agent and its preparation method and application

A polyisocyanate, cyclic diol technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of reducing the NCO group functionality of the curing agent, the crosslinking density and water dispersibility of the coating film, and the medium resistance of the coating film. and mechanical properties, solvent resistance and mechanical strength of the coating film, etc., to achieve good transparency and gloss, improve and medium resistance, and good medium resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of cyclic diol modified water-based polyisocyanate curing agent

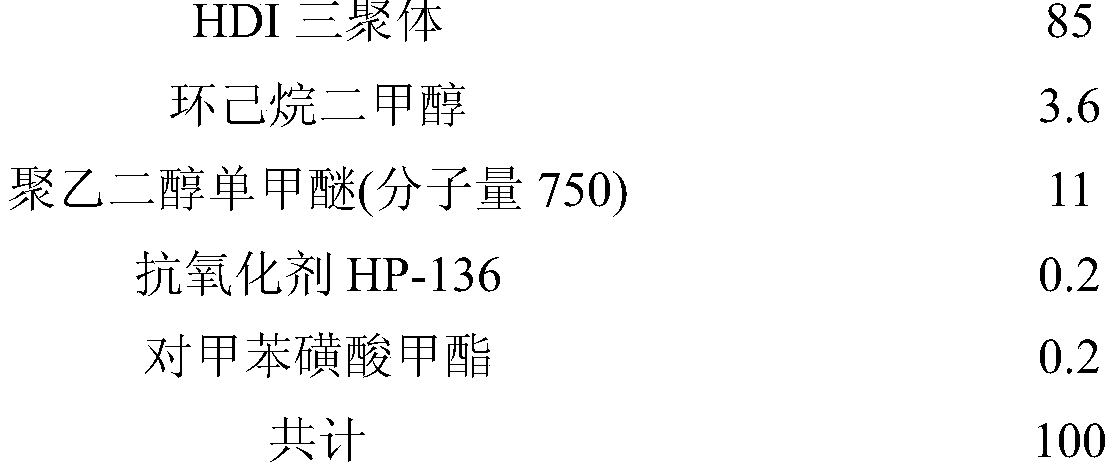

[0028] The type and mass percentage of each component raw material:

[0029]

[0030] Preparation process: Under the protection of nitrogen, add HDI trimer and antioxidant HP-136 to the reaction kettle in sequence, heat up to 60°C, and mix cyclohexane dimethanol and polyethylene glycol monomethyl ether (molecular weight 750) Add it dropwise into the system within 50 minutes, react for 6 hours, and when the NCO content of the system reaches the theoretical value, add the terminator methyl p-toluenesulfonate to terminate the reaction, and obtain a cyclic diol-modified water-based polyisocyanate curing agent .

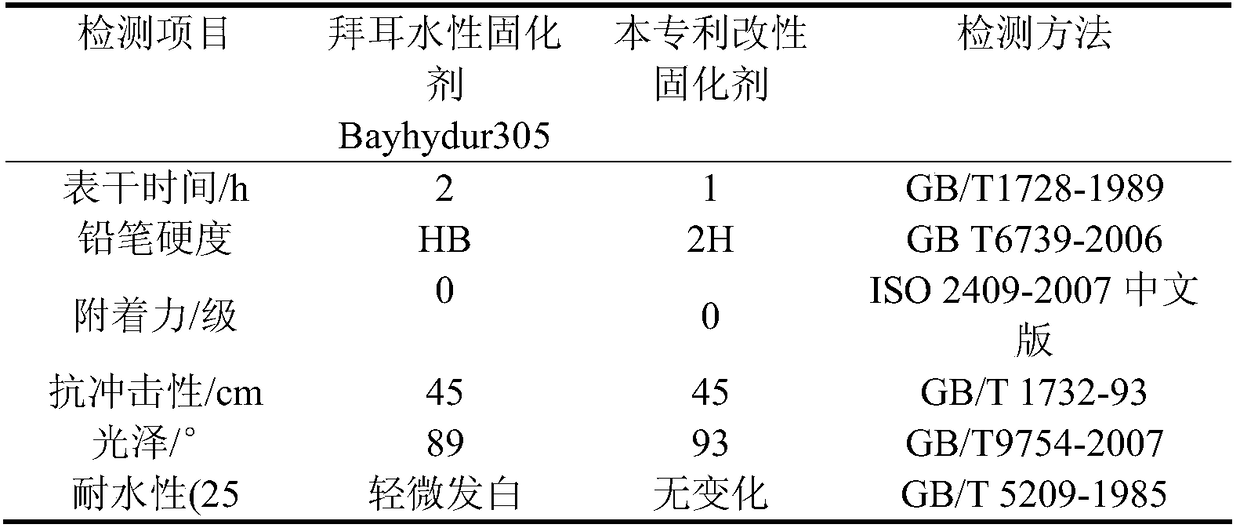

[0031] (2) Performance of cyclic diol-modified water-based polyisocyanate curing agent: a colorless transparent viscous liquid with a viscosity (25°C) of 3100mPa·s, an NCO content of 18.5%, and a solid content of 100%;

[0032] (3) Preparation of 2K-WPU coating:

[0033] The pre...

Embodiment 2

[0040] (1) Preparation of cyclic diol modified water-based polyisocyanate curing agent

[0041] The type and mass percentage of each component raw material:

[0042]

[0043] Preparation process: Under the protection of nitrogen, add HDI trimer, IPDI trimer mixture, antioxidant Irgafos 168 to the reaction kettle in sequence, raise the temperature to 55°C, add 1,4-cyclohexanedimethanol, polyethylene glycol Add the mixed solution of monomethyl ether (molecular weight 1000) into the system dropwise within 50 minutes, react for 8 hours, and when the NCO content in the system reaches the theoretical value, add the terminator p-benzoyl chloride to terminate the reaction, and the cyclic diol can be obtained Modified water-based polyisocyanate curing agent;

[0044] (2) Performance of cyclic diol-modified water-based polyisocyanate curing agent: a colorless transparent viscous liquid with a viscosity (25°C) of 5000mPa·s, an NCO content of 14.9%, and a solid content of 100%;

[00...

Embodiment 3

[0051] (1) Preparation of cyclic diol modified water-based polyisocyanate curing agent

[0052] The type and mass percentage of each component raw material:

[0053]

[0054]

[0055] Preparation process: under the protection of nitrogen, add HDI-TDI mixed trimer, antioxidants (Irganox 245 and Irgafos 264), hydroquinone bishydroxyethyl ether (HQEE) to the reactor in sequence, and heat up to 65 ° C. Add polyethylene glycol monomethyl ether (molecular weight: 400) into the system dropwise within 25 minutes, react for 6 hours, and when the NCO content in the system reaches the theoretical value, add the terminator phosphoric acid to terminate the reaction, and the cyclic diol can be obtained Modified water-based polyisocyanate curing agent;

[0056] (2) Performance of cyclic diol-modified water-based polyisocyanate curing agent: a colorless transparent viscous liquid with a viscosity (25°C) of 8500mPa·s, an NCO content of 13.8%, and a solid content of 100%;

[0057] (3) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com