Polyether modified polyurethane curing agent and preparation method thereof

A polyurethane curing agent and polyether modification technology, applied in polyurea/polyurethane coatings, coatings, primers, etc., can solve problems such as cracking, prevent cracking of the paint film, facilitate product performance balance, and excellent flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a kind of preparation method of above-mentioned polyether modified polyurethane curing agent, comprises the steps:

[0039] Mix the polyether, trimethylolpropane, toluene diisocyanate, a part of the auxiliary agent and the solvent to obtain a mixture A;

[0040] Heat up the mixture A at a temperature of 65°C±5°C, keep it warm for 1h-1.5h, continue to raise the temperature at a temperature of 75°C±5°C, keep it warm for 2h-3h, and obtain a mixture B;

[0041] When the content of NCO in the system is 11-14, add a part of the auxiliary agent and solvent to the mixture B to obtain the mixture C;

[0042] When the content of NCO in the system is 7-10, add a part of the auxiliary agent and solvent to the mixture C to obtain the mixture D;

[0043] Add a part of the auxiliary agent and solvent to the mixture D, and cool down to obtain the mixture.

[0044] The invention imparts excellent flexibility to the modified curing agent by introducing...

Embodiment 1

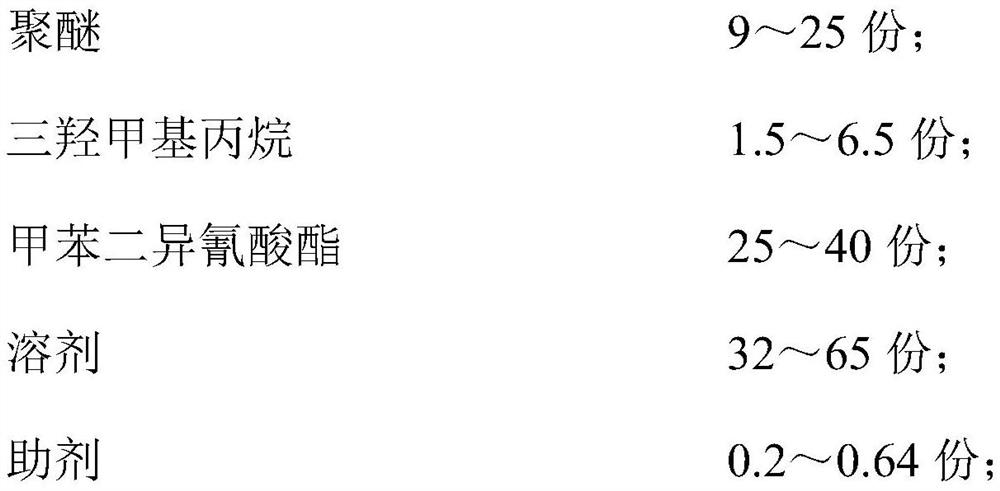

[0054] This embodiment provides a polyether modified polyurethane curing agent, which consists of the following components by weight:

[0055] 25 parts of polyether, 1.9 parts of trimethylolpropane; 25.0 parts of toluene diisocyanate; 20 parts of sec-butyl acetate; 3.65 parts of ethyl acetate; 0.15 parts of antioxidant stabilizer; 0.04 parts of catalyst; 0.028 parts of terminator; water absorbing agent 0.1 part; 24.132 parts of esters in dilute solvent, including 16.132 parts of sec-butyl acetate and 8.0 parts of dimethyl carbonate in the dilute solvent of esters;

[0056] The polyether is compounded by a difunctional polyether: a trifunctional polyether in a mass ratio of 6:4;

[0057] The difunctional polyether is DL-2000D of Shandong Bluestar Dongda Chemical Industry, the hydroxyl value is 54mgKOH / g-58mgKOH / g, and the number average molecular weight is 2000g / mol;

[0058] The trifunctional polyether is DV-125 produced by Shandong Bluestar Dongda Chemical Co., Ltd., the hyd...

Embodiment 2

[0067] This embodiment provides a polyether modified polyurethane curing agent, which consists of the following components by weight:

[0068] 18 parts of polyether; 2.1 parts of trimethylolpropane; 30.0 parts of toluene diisocyanate; 20 parts of sec-butyl acetate; 3.65 parts of ethyl acetate; 0.15 parts of antioxidant stabilizer; 0.06 parts of catalyst; 0.04 parts of terminator; 0.1 part; 25.9 parts of esters in dilute solvent, comprising 17.9 parts of sec-butyl acetate and 8.0 parts of dimethyl carbonate in the dilute solvent of esters;

[0069] The polyether is compounded from difunctional polyether: trifunctional polyether at a mass ratio of 5:5;

[0070] The difunctional polyether is DL-400 of Shandong Bluestar Dongda Chemical Industry Co., Ltd., the hydroxyl value is 270mgKOH / g-290mgKOH / g, and the number average molecular weight is 400g / mol;

[0071] The trifunctional polyether is DV-125 produced by Shandong Bluestar Dongda Chemical Co., Ltd., the hydroxyl value is 440 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com