A kind of flame-retardant graphene polyurethane composite foam material and preparation method thereof

A technology of syntactic foam and graphene, applied in the field of materials, can solve the problems of accelerating heat loss and burning speed, death by suffocation, increase in apparent density of polyurethane foam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

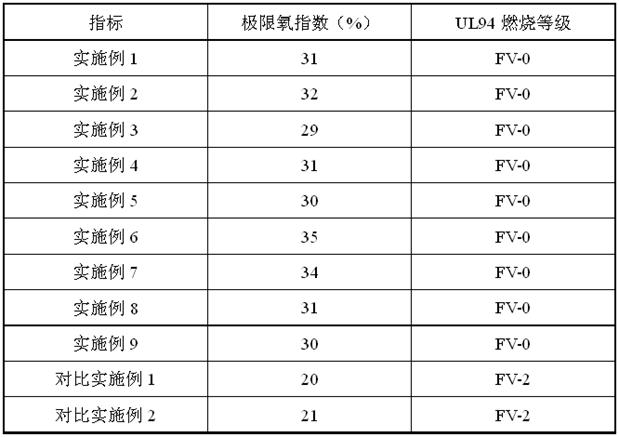

Examples

Embodiment 1

[0027] Example 1 A flame-retardant graphene polyurethane composite foam material is prepared from a component of mass (g / g): 20% ethylene glycol, 20% aliphatic polyester polyol, 50% isocyanate. , 3%, trivin diamine 2%, graphene-inorganic salt flame retardant 4%, and 1% dimethylsilicone oil.

[0028] Among them: the blowing agent refers to a mixture of monofluoroethane and azo dimethylamide in combination of 1: 2 mass ratio (g / g).

[0029] The graphene-inorganic salt flame retardant refers to dissolving 60 g of graphene and inorganic salts in 1L deionized water, with a non-covalent interaction between graphene and inorganic salts, such as hydrogen bonds, Van Dew Hui, electrostatic interaction The equal interface assembles a super molecule flame retardant, which is then frozen to give a solid graphene-inorganic salt flame retardant. Ordinary graphene: sodium chloride: ammonium phosphate = 3: 1: 2 (g / g).

[0030] The preparation method of the flame retardant graphene polyuretha...

Embodiment 2

[0035] Example 2 A flame-retardant graphene polyurethane composite foam material is prepared from a component of mass (g / g): polyether polyol 20%, aromatic cyclic polyester polyol containing aromatic ring structure 15%, isocyanate 47%, 1,1,1,3,3-pentafluorobutane 6%, N, N-dimethylcyclohexylamine 5%, graphene-inorganic salt flame retardant 6%, dimethyl The base silicone oil is 1%.

[0036] The preparation method of the flame retardant graphene polyurethane composite foam material is in Example 1.

[0037] Among them: The polyether polyol refers to a mixture of a mixture of a mixture of diethylene glycol and ethylene glycol in a mass ratio (g / g) of 2: 1.

[0038] The preparation method of graphene-inorganic salt flame retardant is in Example 1, an oxide: ammonium chloride: s2: 2: 1: 2 (g / g).

Embodiment 3

[0039]Example 3 A flame retardant polyurethane graphene embodiment composite foam material which is prepared from the following mass% (g / g) of the components: 15% of diethylene glycol, an aliphatic polyester polyol of 25%, 45% isocyanate, the foaming agent 4%, N, N- dimethylbenzylamine 3%, graphene - inorganic flame retardants 7%, 1% polyethylene diethyl silicone.

[0040] The preparation method of the flame retardant graphene polyurethane composite foam material is in Example 1.

[0041] Wherein: the blowing agent refers to diisopropyl azodicarboxylate and n-heptane at 3: 1 mixture mass ratio (g / g) obtained by mixing.

[0042] Graphene - inorganic flame retardant prepared in Example 1, modified graphene: reduced graphene oxide: sodium: potassium = 2: 2: 1: 1 (g / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com